Take-up winding facility

A spinning and equipment technology, applied in the field of spinning and winding equipment, can solve the problems of complicated spinning and winding equipment, and achieve the effects of lowering the device height, ensuring silk quality, and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

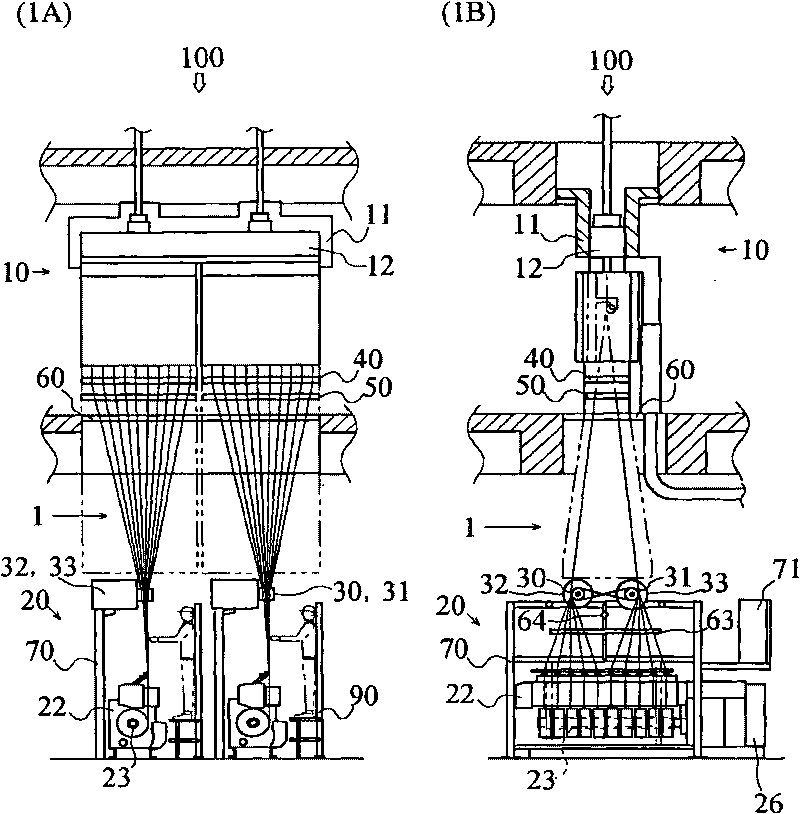

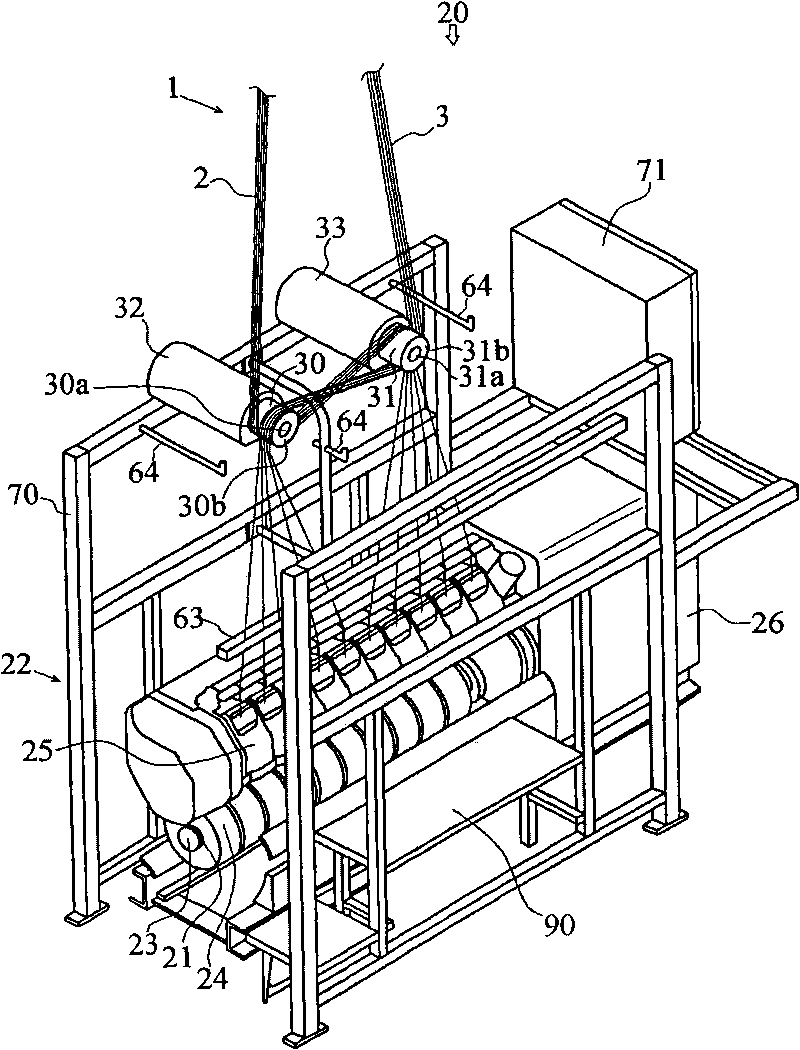

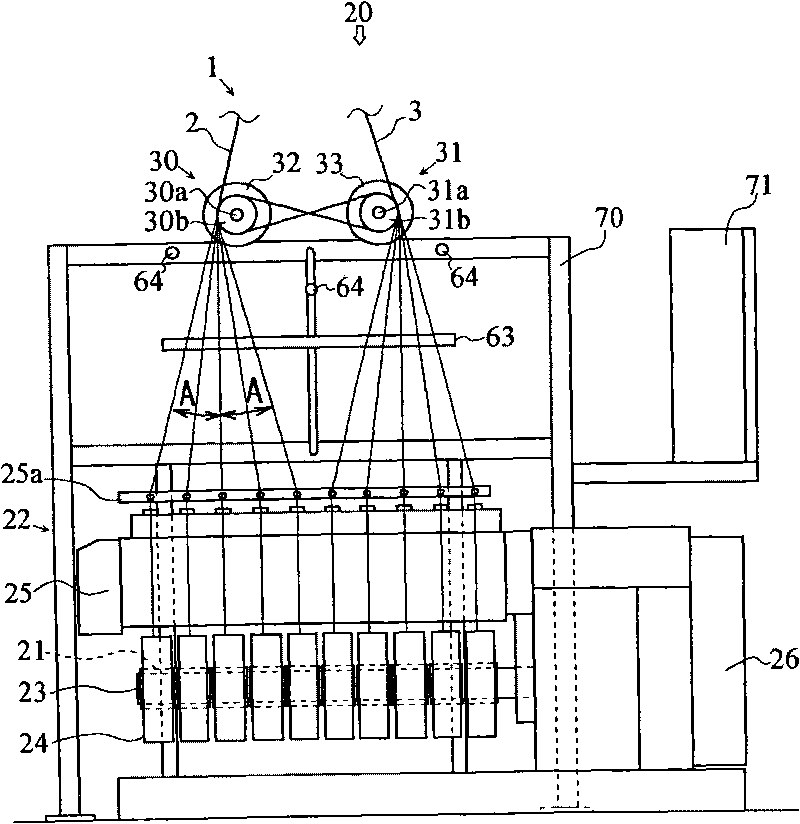

[0064] Next, a spinning winding facility 100 according to a first embodiment of the present invention will be described with reference to the drawings. figure 1 A is a front view of the spinning winding device 100 according to the first embodiment of the present invention, figure 1 B is a side view of the spinning winding device 100 according to the first embodiment of the present invention, figure 2 is a perspective view of the spinning winding device 20, image 3 It is a side view of the spinning winding device 20 . In addition, in the following description, the acting direction of gravity is taken as the vertical direction, and the axis direction of the bobbin holder shaft 23 included in the winding machine 22 described later is taken as the front-rear direction. The side to which the device 26 is connected is referred to as the rear side, and the other side is referred to as the front side. In addition, the winding machine 22 is viewed from the front side, and the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com