Zinc oxide medium and high temperature coal gas fine desulfurizer and preparation method

A desulfurizer, medium-high temperature technology, applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve the problems of low desulfurization precision and poor thermal stability of desulfurizer, and achieve low price, good thermal stability, Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

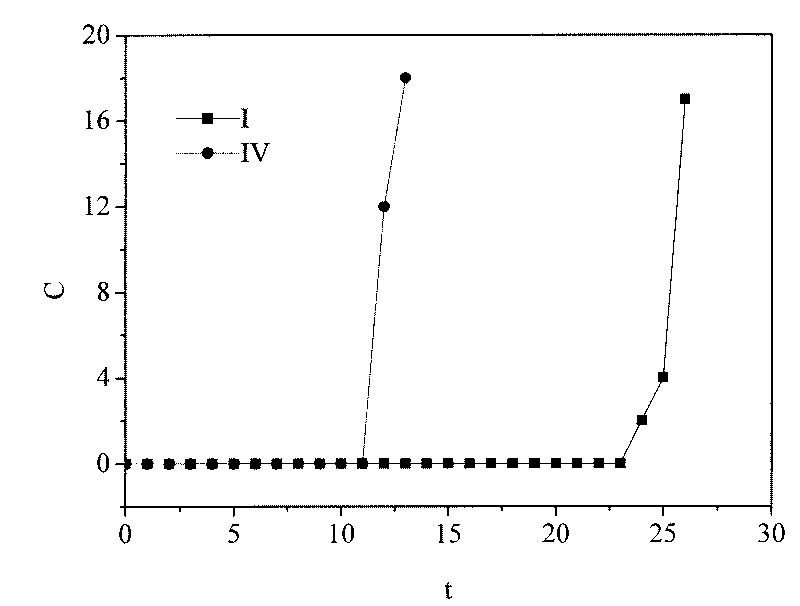

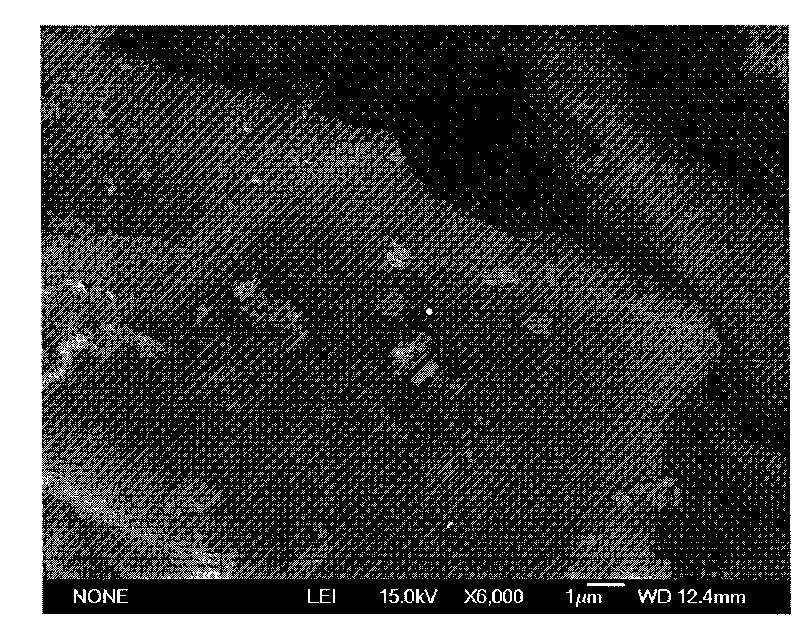

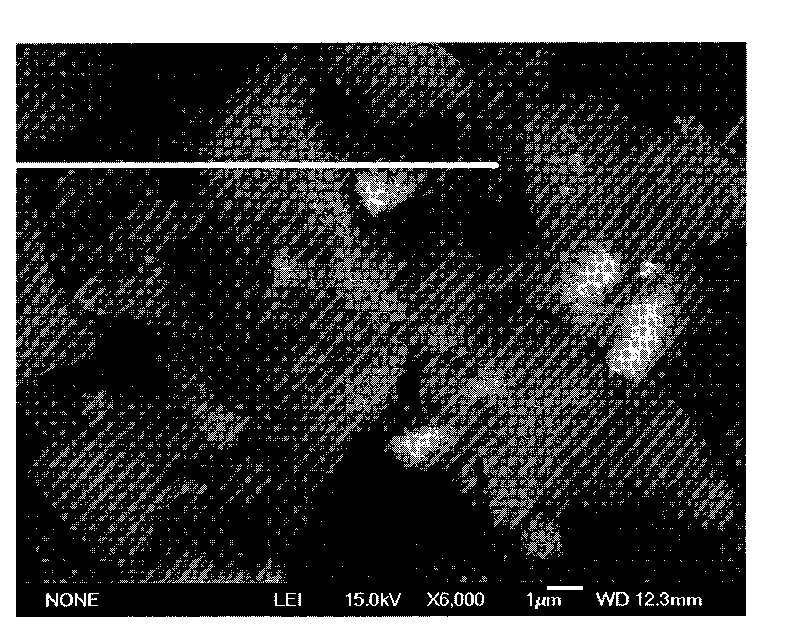

[0019] Embodiment 1: Sieve the semi-coke to obtain 4-8 mesh particles, mix it with a zinc nitrate solution with a mass concentration of 20% at a volume ratio of 0.7:1, put it in an autoclave, and pressurize and impregnate it at 28 atm for 5 hours , and then naturally cooled to room temperature, the sample was taken out, filtered, and dried at 50°C for 5 hours, and then at 100°C for 5 hours, and then dried in N 2 Calcined under purging for 5 hours, and naturally cooled to room temperature to obtain desulfurizer I. The vulcanization experiment was carried out at a temperature of 500°C, and the reaction gas composition (volume ratio) was CO (33%), H 2 (39%), H 2 O (5%), H 2 S (300ppm), N 2 As a balance gas, the air speed is 2000h -1 . h 2 When the S outlet concentration is greater than 1ppm, the sulfur capacity of the desulfurizer is 4.46gS / 100g desulfurizer, and the breakthrough time is 23h. Using the desulfurizing agent preparation method published by patent CN 100443161...

Embodiment approach 2

[0022] Embodiment 2: Sieve the semi-coke to obtain 4-8 mesh particles, mix it with a zinc nitrate solution with a mass concentration of 20% at a ratio of 0.7:1, put it in an autoclave, and pressurize it at 28 atm for 7 hours Naturally cool to room temperature, take out the sample, filter, and dry at 70°C for 5 hours, then at 120°C for 5 hours, and then in N 2 Calcined under purging for 5 hours, and naturally cooled to room temperature to obtain desulfurizer II. The vulcanization experiment was carried out at 500°C, and the reaction gas composition (volume ratio) was CO (33%), H 2 (39%), H 2 O (5%), H 2 S (1000ppm), N 2 As a balance gas, the air speed is 2000h -1 . h 2 When the S outlet concentration is greater than 1ppm, the sulfur capacity and breakthrough time are 4.55gS / 100g desulfurizer and 7.5h, respectively.

Embodiment approach 3

[0023] Embodiment 3: Sieve the semi-coke to obtain 4-8 mesh particles, mix it with a zinc nitrate solution with a mass concentration of 20% at a ratio of 0.7:1, put it in an autoclave, and pressurize it at 20 atm for 5 hours. Naturally cool to room temperature, take out the sample, filter, and dry at 50°C for 5 hours, then at 100°C for 5 hours, and then in N 2 Calcined under purging for 6 hours, and naturally cooled to room temperature to obtain desulfurizer III. The vulcanization experiment was carried out at 500°C, and the reaction gas composition (volume ratio) was CO (33%), H 2 (39%), H 2 O (5%), H 2 S (1000ppm), N 2 As a balance gas, the air speed is 2000h -1 . h 2 The sulfur capacity and breakthrough time when the S outlet concentration is greater than 1ppm are 6.57gS / 100g desulfurizer and 16h, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com