Additive for cellulose ester resin, cellulose ester resin composition using same, and film

A technology of cellulose ester resin and composition, applied in the field of additives for cellulose ester resin, to achieve the effect of excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

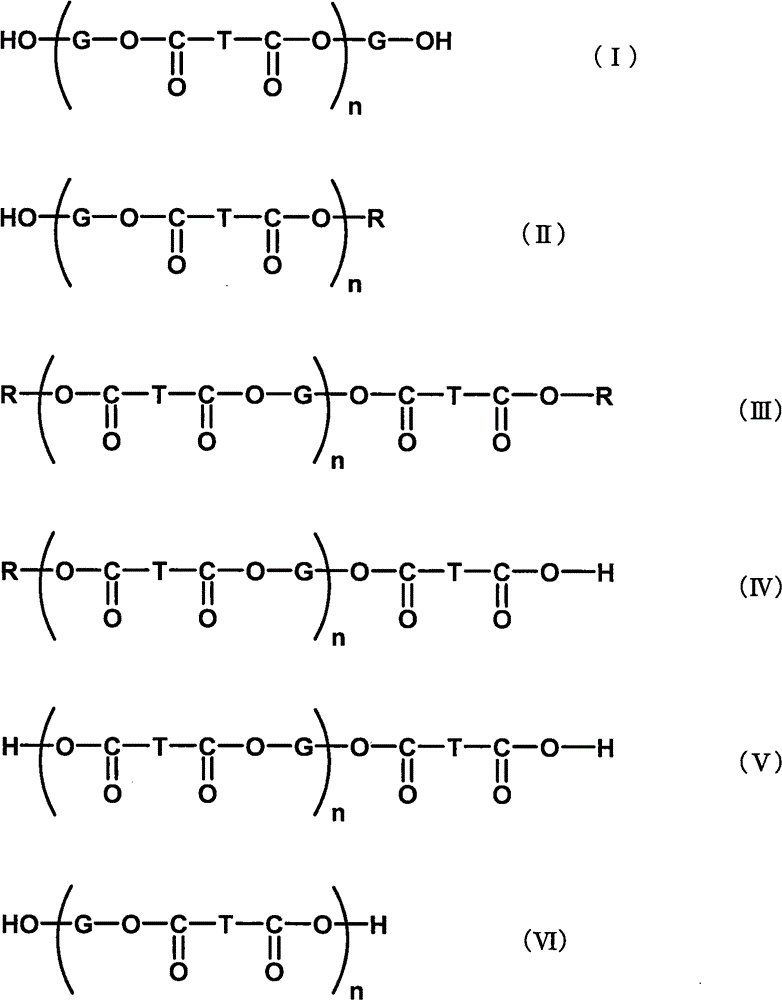

Method used

Image

Examples

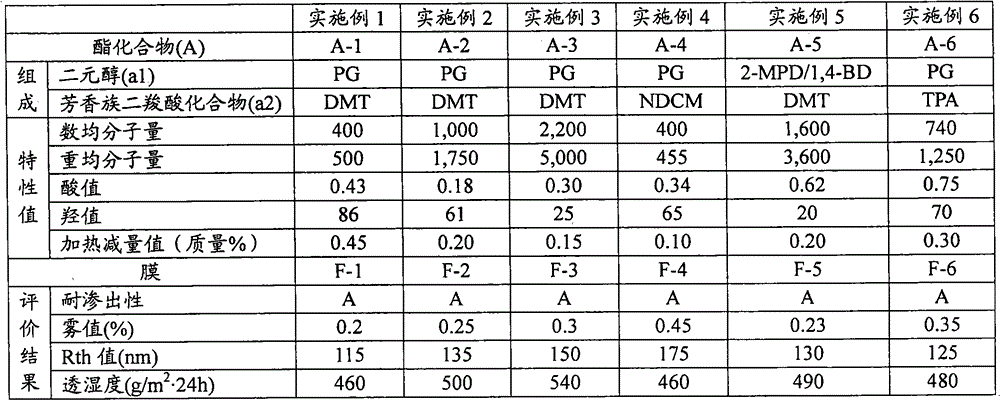

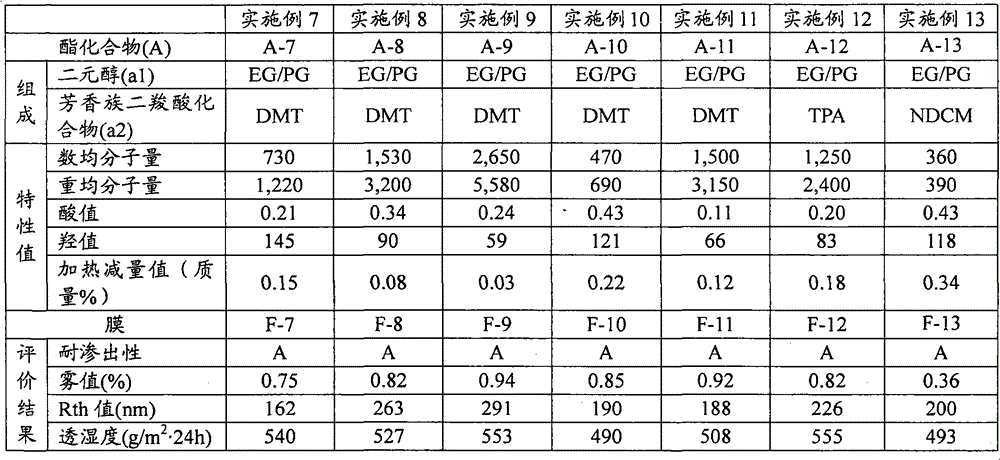

Embodiment 1

[0109] The manufacture of embodiment 1 ester compound (A-1)

[0110] Add 392 g of 1,2-propanediol (hereinafter referred to as "PG") and dimethyl terephthalate (hereinafter referred to as "DMT") to a four-necked flask with an internal volume of 3 liters equipped with a thermometer, a stirrer and a reflux cooler. ”)800g and heat up. When the temperature in the flask reached 130°C, tetraisopropyl titanate as an esterification catalyst was added at 60 ppm relative to the total amount of PG and DMT, and the generated methanol was distilled off at 185°C while stirring under a nitrogen stream, and the reaction 15 hours. After the reaction, when the temperature in the flask reached 190° C., the pressure was reduced at about 4000 Pa for 2 hours to obtain an ester compound (A-1) (acid value: 0.43, hydroxyl Value: 86).

Embodiment 2

[0111] The manufacture of embodiment 2 ester compound (A-2)

[0112] 940 g of PG and 1,600 g of DMT were put into a four-necked flask with an internal volume of 3 liters equipped with a thermometer, a stirrer, and a reflux cooler, and the temperature was raised. When the temperature in the flask reached 130°C, tetraisopropyl titanate as an esterification catalyst was added at 60 ppm relative to the total amount of PG and DMT, and the generated methanol was distilled off at 185°C while stirring under a nitrogen stream, and the reaction 10 hours. After the reaction, when the temperature in the flask reached 190°C, the pressure was reduced at about 4,000 Pa for 2 hours, and further at about 133 Pa for 1 hour to obtain an ester compound (A- 2) (acid value: 0.18, hydroxyl value: 61).

Embodiment 3

[0113] The manufacture of embodiment 3 ester compound (A-3)

[0114] 1,500 g of the ester compound (A-2) obtained in Example 2 was charged into a four-necked flask with an internal volume of 2 liters, and the temperature was raised. When the temperature in the flask reached 190°C, the pressure was reduced at about 133 Pa for 1.5 hours to obtain an ester compound (A-3) with a number average molecular weight of 2,200 and a weight average molecular weight of 5,000 (acid value: 0.30, hydroxyl value: 25) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com