Synthesis method of N-methyl-2-hydroxyethyl hydroxyethyl

A technology of hydroxyethylpyrrolidine and a synthesis method, applied in directions such as organic chemistry, can solve problems such as high production cost and low yield, and achieve the effects of short synthesis route, mild reaction conditions and high industrial production value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

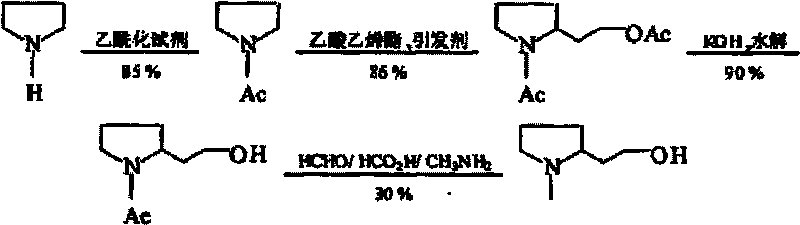

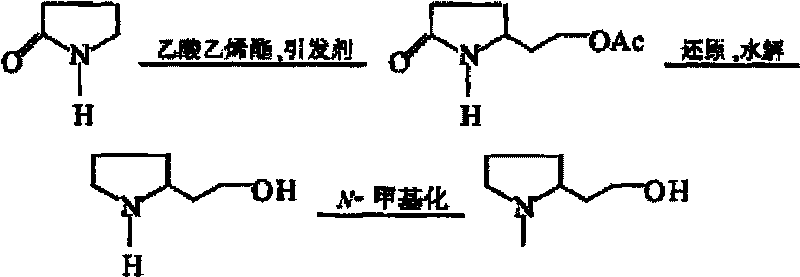

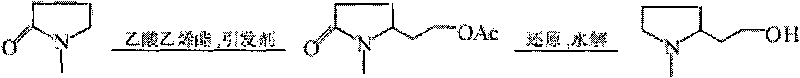

Method used

Image

Examples

Embodiment 1

[0029] Take a 1000ml three-neck flask, add 140ml of dimethyl sulfate and 140ml of N-methylpyrrolidone, raise the temperature to 60°C, and keep the temperature at 60-75°C for 3 hours. After completion, cool to 5°C, add 145ml of ethyl cyanoacetate dropwise, and react below 20°C for 3 hours, filter, and dry to obtain about 240g of intermediate (I), with a yield of 86.7%.

Embodiment 2

[0031] Take a 1000ml three-neck flask, add 140ml dimethyl sulfate and 140ml N-methylpyrrolidone, raise the temperature to 50°C, and keep it at 50-60°C for 3 hours. After completion, cool to 5°C, add 145ml of ethyl cyanoacetate dropwise, and react below 20°C for 3 hours, filter, and dry to obtain about 205g of intermediate (I), with a yield of 74.0%.

Embodiment 3

[0033] Take a 1000ml three-neck flask, add 140ml of dimethyl sulfate and 140ml of N-methylpyrrolidone, raise the temperature to 75°C, and keep it at 75-80°C for 3 hours. Finished, then cooled to 5°C, added dropwise 145ml of ethyl cyanoacetate, after dropping, reacted below 20°C for 3 hours, filtered, and dried to obtain about 130g of intermediate (I), with a yield of 46.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com