Electrostatic atomizer

An electrostatic sprayer, high-voltage electrostatic generation technology, applied in the direction of electrostatic spraying device, spraying device, spraying electric energy device, etc., can solve the problems of poor reliability of electrostatic generator, abnormal operation of oscillator, not easy to be small and compact, etc., and achieve small appearance and volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

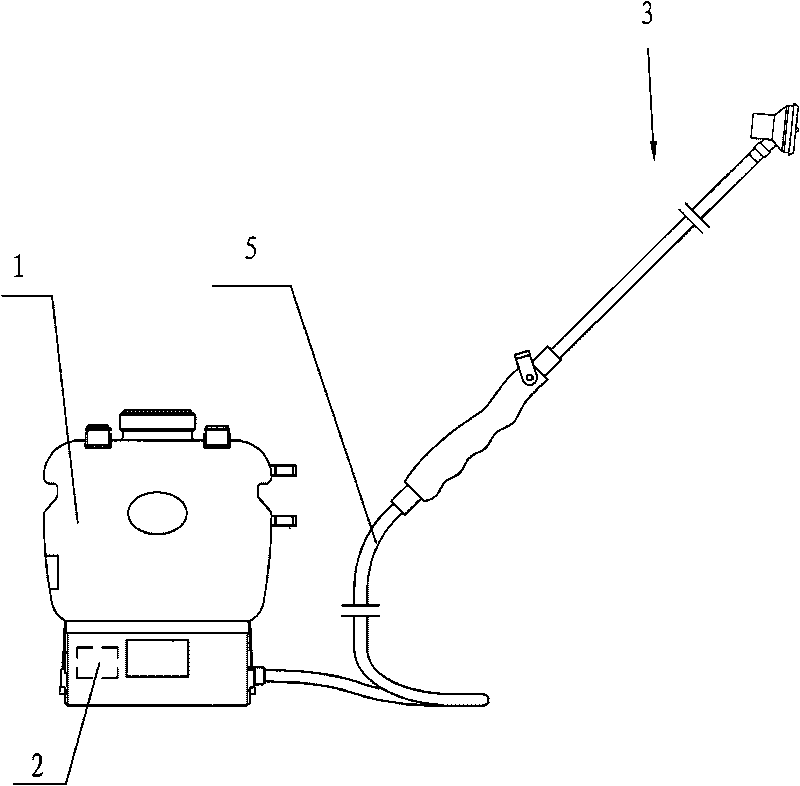

[0031] as attached image 3 An electrostatic sprayer shown includes a liquid storage container 1 , a high-voltage electrostatic generating device 2 with positive and negative electrodes, a connecting hose 5 , and a spray gun 3 . One end of the connecting hose 5 communicates with the liquid storage container 1 , and the other end of the connecting hose 5 communicates with the rear end of the spray gun 3 .

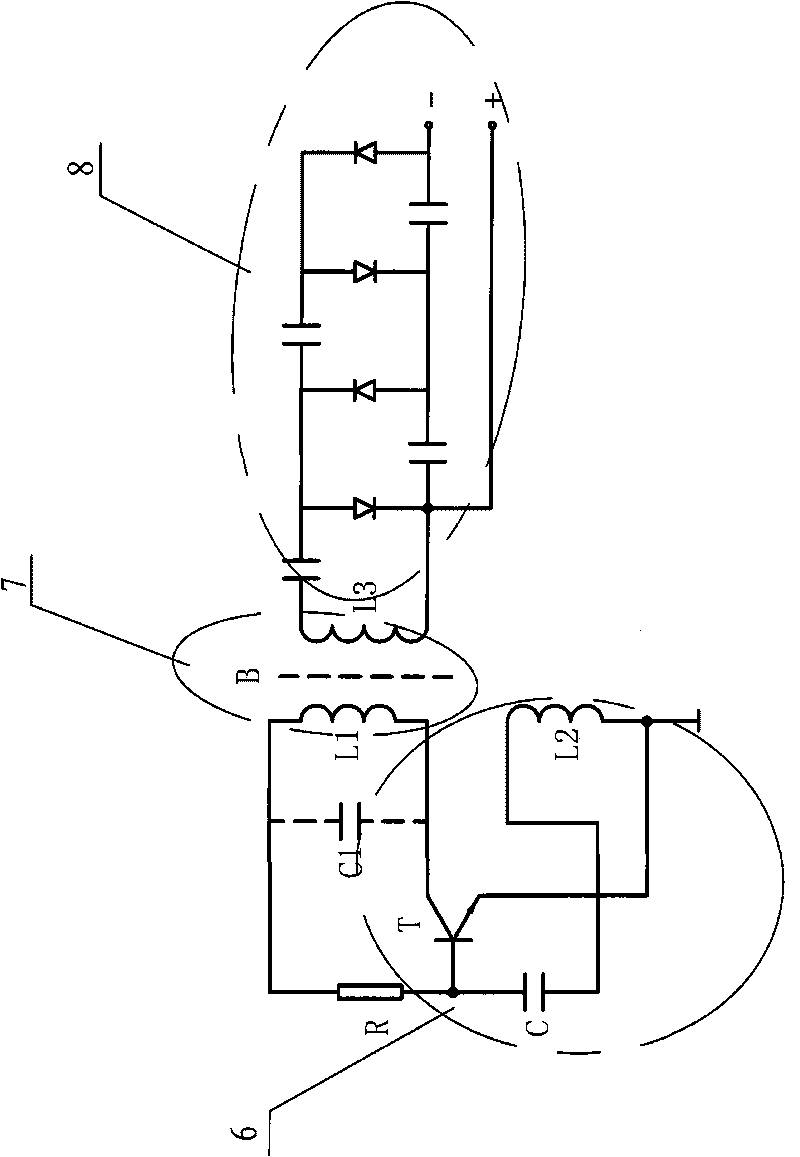

[0032] as attached Figure 4 Shown, described high-voltage electrostatic generator 2 comprises:

[0033] A power inverter circuit 6, the power inverter circuit 6 is used to transform a low-voltage DC power supply into a high-frequency AC power supply;

[0034] High-frequency transformer 7, its input end is electrically connected with the output end of described power inverter circuit 6, and described high-frequency transformer 7 is used fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap