Probiotic active product and preparation method thereof

A probiotic and active technology, applied in the field of active probiotic products and their manufacturing, can solve problems such as microbial imbalance and affect the survival of beneficial bacteria, and achieve the effects of cost reduction and survival rate improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

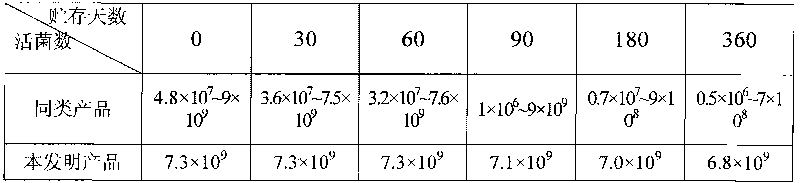

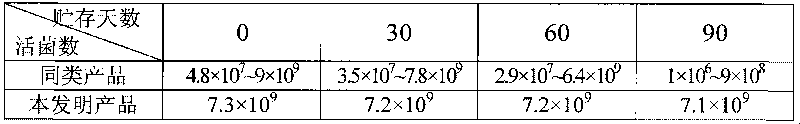

Examples

Embodiment 1

[0029]Take 5 parts of milk powder, 5 parts of soybean powder and 90 parts of water to prepare a culture medium. The prepared culture medium is sterilized at 110°C for 20 minutes, and then cooled to 35°C; the percentage by weight is 3% for bifidobacteria and 97% for the medium Inoculate the strains at a ratio of 37°C for 20 hours, when the acidity is 55°T, cool the fermentation broth to 5°C, and end the cultivation; take another sterilized medium, cool it to 45°C, press 2% Lactobacillus bulgaricus, 2% Streptococcus thermophilus, 96% of the culture medium was inoculated with strains, and then cultured at 43°C for 3 hours. At this time, the acidity was 60°T, and the fermentation liquid was cooled to 5°C to end the cultivation .

[0030] Centrifuge the above two cultured fermentation liquids at a temperature of 15°C and a rotational speed of 3500r / min for 15 minutes, pour off the supernatant, collect the obtained bacteria, and then add 20 parts of trehalose as a freeze-drying prot...

Embodiment 2

[0032] Take 7 parts of milk powder, 7 parts of soybean powder and 86 parts of water to prepare a culture medium. The prepared culture medium is sterilized at 115°C for 15 minutes, and cooled to 37°C; the percentage by weight is 2% for bifidobacteria and 98% for the culture medium Proportionally inoculated strains, and then cultured at 37°C for 15 hours. At this time, the acidity was 50°T. The fermentation broth was cooled to 9°C to end the cultivation; Bacillus 1%, Streptococcus thermius 1%, 98% of the culture medium was inoculated with strains, and then cultured at 43°C for 5 hours. At this time, the acidity was 50°T. The fermentation broth was cooled to 9°C to end the cultivation.

[0033] Centrifuge the above two cultured fermentation liquids at a temperature of 20°C and a rotational speed of 3000r / min for 10 minutes, pour off the supernatant, collect the obtained bacteria, and then add 10 parts of trehalose as a freeze-drying protective agent. Put it in a vacuum freeze dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com