Milk oligopeptide added liquid milk and preparation method thereof

A liquid milk and oligopeptide technology, which is applied in milk preparations, dairy products, applications, etc., can solve the problems of high production cost and high energy consumption, and achieve the effect of high absorption rate, good taste and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

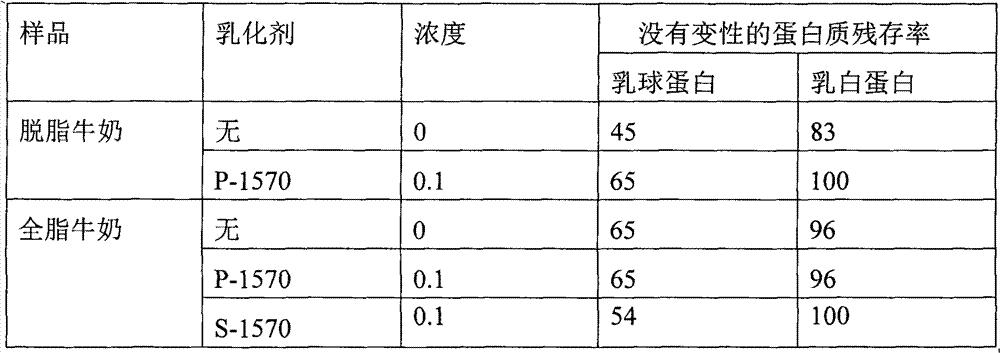

Method used

Image

Examples

Embodiment 1

[0027] The composition of every 1000 parts of liquid milk (by weight):

[0028] Milk 993.8 parts

[0029] Milk oligopeptide 3.0 parts

[0030] Carrageenan 0.1 parts

[0031] Sodium alginate 0.5 parts

[0032] Sucrose fatty acid ester S-1570 (HLB value 15) 0.8 parts

[0033] Glyceryl monostearate 0.7 parts

[0034] Edible essence 1.0 parts

[0035] Iron element multi-nutrient package 0.1 part

[0036] Among them, the HLB value of the total emulsifier is 9.63

[0037] Preparation:

[0038] 1. Milk inspection: the fat, protein, dry matter and other indicators should meet the secondary standards set by the applicant: fat ≥ 3.3%, protein ≥ 3.00%, dry matter ≥ 11.85%, acidity ≤ 17°, the Raw milk should be refrigerated below 4°C;

[0039] 2. Ingredients: Put an appropriate amount of the above-mentioned milk into the chemical material tank, heat it to 65-70°C, add carrageenan, sodium alginate, monostear fatty acid glyceride, sucrose fatty acid ester, and use three Stir with ...

Embodiment 2

[0050]The composition of every 1000 parts of liquid milk (by weight):

[0051] Milk 946.85 parts

[0052] Milk oligopeptide powder 5 parts

[0053] 45 parts white sugar

[0054] Sodium alginate 0.5 parts

[0055] Glyceryl monostearate 0.5 parts

[0056] Sucrose fatty acid ester S-1570 (HLB value 15) 0.95 parts

[0057] 1 serving spices

[0058] Iron element multi-nutrient package 0.2 servings

[0059] Among them, the HLB value of the total emulsifier is 11

[0060] The preparation method and product characteristics of the liquid milk are the same as in Example 1. Adding dissolved white sugar in the batching process

[0061] process.

Embodiment 3

[0063] The composition of every 1000 parts of liquid milk (by weight):

[0064] Milk 991.2 parts

[0065] 4 servings of milk oligopeptide

[0066] 1 part honey

[0067] Diglycerin fatty acid ester 0.4 parts

[0068] Sucrose fatty acid ester P-1570 (HLB value 15) 1.1 parts

[0069] 1 part microcrystalline cellulose

[0070] 1 serving spices

[0071] 0.3 servings of complex nutrients

[0072] The preparation method and product characteristics of the liquid milk are the same as in Example 1. The process of dissolving honey is added to the batching process.

[0073] Among them, the HLB value of the total emulsifier is 10.97

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com