Drinking yoghourt and making method thereof

A production method and drinking-type technology, applied in milk preparations, applications, dairy products, etc., can solve the problems of increasing the difficulty of packaging recycling and reuse, sticking to the inner wall of the packaging container, and being difficult to drink, etc., to achieve good taste and flavor , good flavor, full-bodied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

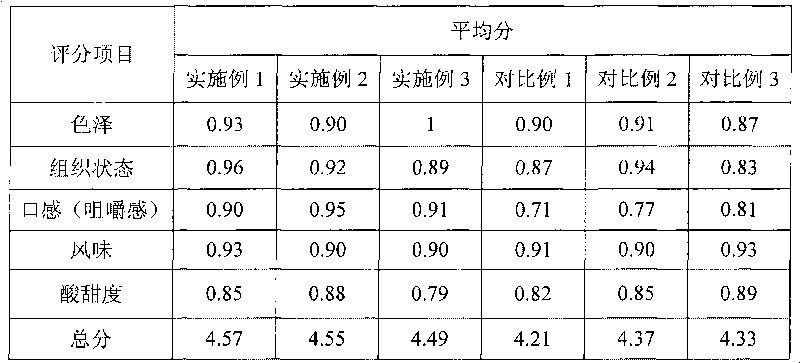

Embodiment 1

[0036] Embodiment 1, plain drinking yoghurt and its preparation method

[0037] 1. Yogurt formula: 47.84% milk for ingredients, 2.5% cream (38% fat content), 7.45% white sugar, 0.53% tapioca starch, 6.4% whey powder, 0.02% pectin, 0.01% gelatin, appropriate amount of bacteria , the balance of water for ingredients.

[0038] 2. Production method:

[0039] 1) Raw milk: select high-quality, safe and qualified fresh milk as the main raw material for standardization;

[0040] 2) Ingredients: Raise the temperature of the raw milk to 60°C, dry mix white granulated sugar and powdered raw materials, add them to the raw milk for compounding, and the time is about 25 minutes to obtain a prepared liquid;

[0041] 3) Stand still at low temperature: cool down the melted feed solution to 5°C, and let stand for 30 minutes;

[0042] 4) Homogenization: preheat the above-mentioned feed liquid after standing still to 65°C for homogenization, and the homogenization pressure is 200Bar;

[0043]...

Embodiment 2

[0049] Embodiment 2, real fruit grain drinking yogurt and its preparation method

[0050] 1. Yogurt formula: 90% yogurt base, 10% fruit jam; of which:

[0051] Yogurt base formula: milk for ingredients 58.3%, cream 2.35% (fat content 40%), white sugar 6.0%, tapioca starch 0.55%, whey powder 6.4%, pectin 0.01%, gelatin 0.01%, strain Appropriate amount, the balance of water for ingredients;

[0052] Fruit jam: commercially available sweet orange velvet jam, soluble solids Brix (%) 28, pH value (20°C) about 4.3, fruit net content about 30% (commercially available coconut fruit jam, yellow Peach fruit jam, etc., the diameter of the fruit should be controlled at about 3mm×3mm×3mm, and it should not be too large, otherwise it will easily cause choking).

[0053] 2. The method for making the yogurt base material: the production method is basically the same as in Example 1, and the fermented yogurt base material is obtained;

[0054] 3. Mixing and filling of jam and yogurt base mat...

Embodiment 3

[0056] Embodiment 3, sugar-free plain drinking yoghurt and its preparation method

[0057] 1. Yogurt formula: milk for ingredients 55.3%, cream 2% (fat content 55%), xylitol 7.5%, tapioca starch 0.45%, whey powder 6.9%, pectin 0.02%, gelatin 0.02%, bacteria Appropriate amount of ingredients, balance of water for ingredients.

[0058] 2. Production method:

[0059] 1) Raw milk: select high-quality, safe and qualified fresh milk as the main raw material for standardization;

[0060] 2) Ingredients: heat the raw milk to 55°C, dry mix xylitol and powdered raw materials into the raw milk for about 25 minutes, and obtain a prepared liquid;

[0061] 3) Stand still at low temperature: cool down the melted feed solution to 10°C and let stand for about 20 minutes;

[0062] 4) Homogenization: preheat the static feed liquid to 70°C for homogenization, and the homogenization pressure is 180Bar;

[0063] 5) Sterilization: Sterilize the homogenized material liquid, and the sterilization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com