Clamping and positioning device of K-shaped linear ultrasonic motor based on continuous amplitude transformer principle

A linear ultrasonic motor, clamping and positioning technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Guaranteeing the stability of stator motion and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

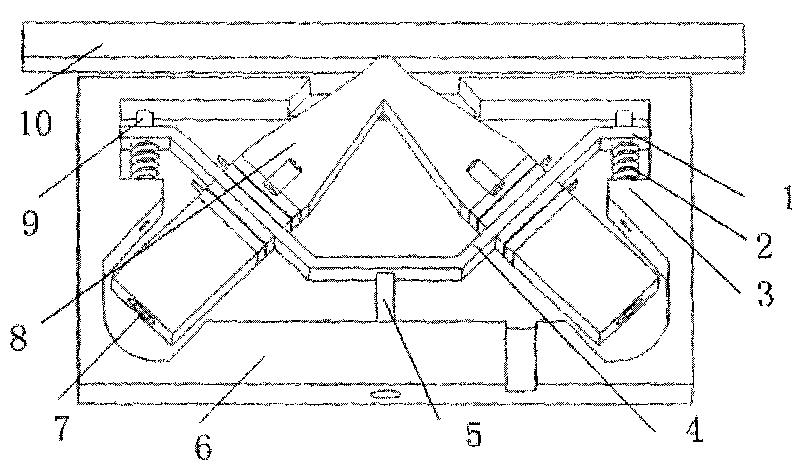

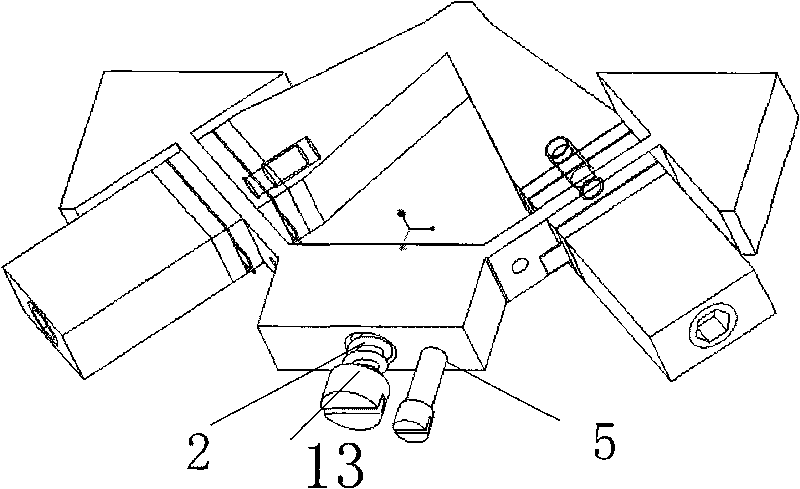

[0016] Specific embodiment 1: A clamping and positioning device for a linear ultrasonic motor such as figure 1 shown. Its characteristics are: 1. The stator and the supporting part 1 are connected by a compression spring 2 and a cylindrical rail 9, and the clamping parts include a cylindrical rail 9, a compression spring 2, and an open rectangular outer frame 6. The cylindrical rail 9 is fixedly connected with the open rectangular outer frame 6 with screws. The compression spring 2 and the cylindrical rail 2 are divided into two left and right sides, and the axial direction is perpendicular to the direction of motion of the guide rail 10 . The arm tail 1 is a transverse rectangular plate, on which there are circular holes equivalent to the diameter of the cylindrical rail. The compression spring 2 is installed on the cylindrical rail 9, and is clamped between the arm tail 1 and the boss 2. The two Langevin vibrators are fixed on the clamping part, so the Langevin vibrators...

specific Embodiment approach 2

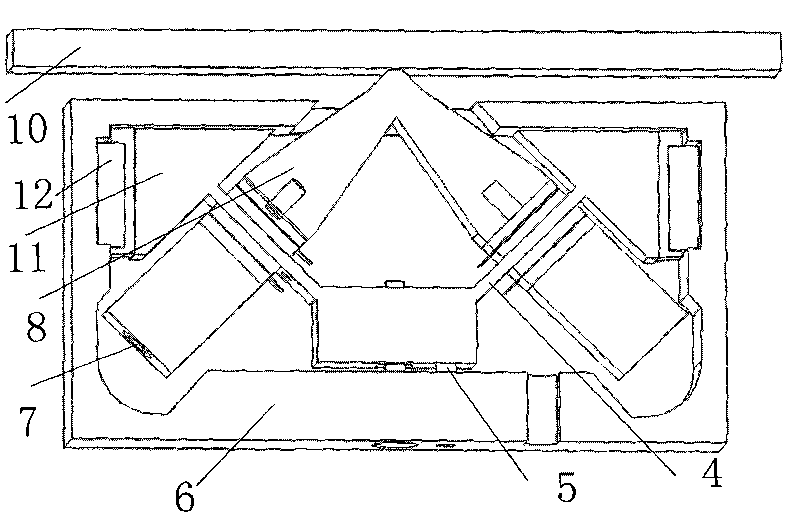

[0018] Specific embodiment 2: A clamping and positioning device for a linear ultrasonic motor such as figure 2 shown. Its characteristics are: 1. The stator and the clamping part are connected by slide rails, and the clamping part includes a slide block 11, a limit slide rail 12 and an open rectangular outer frame 6. Between the limit slide rail 12 and the open rectangular outer frame, between the support arm 4 and the slide block 11, all are fixedly connected with screws. The slide rail is divided into two left and right sides, and its sliding direction is perpendicular to the moving direction of the guide rail 10 . The clamping part fixes the two Langevin vibrators, so the movement of the Langevin vibrators is realized through the slide rail. This device limits the displacement and rotation of the stator in other directions, thereby reducing the useless work of the stator and improving efficiency. 2. The preload can be applied and measured, including the compression bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com