Battery inspection system

A technology for inspection devices and batteries, which is applied in the directions of measuring devices, secondary battery manufacturing, and secondary battery repair/maintenance, etc., can solve the problems of shaking electrode contours, large amount of handover movement of batteries 102, and inability to increase inspection speed, etc. Check the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

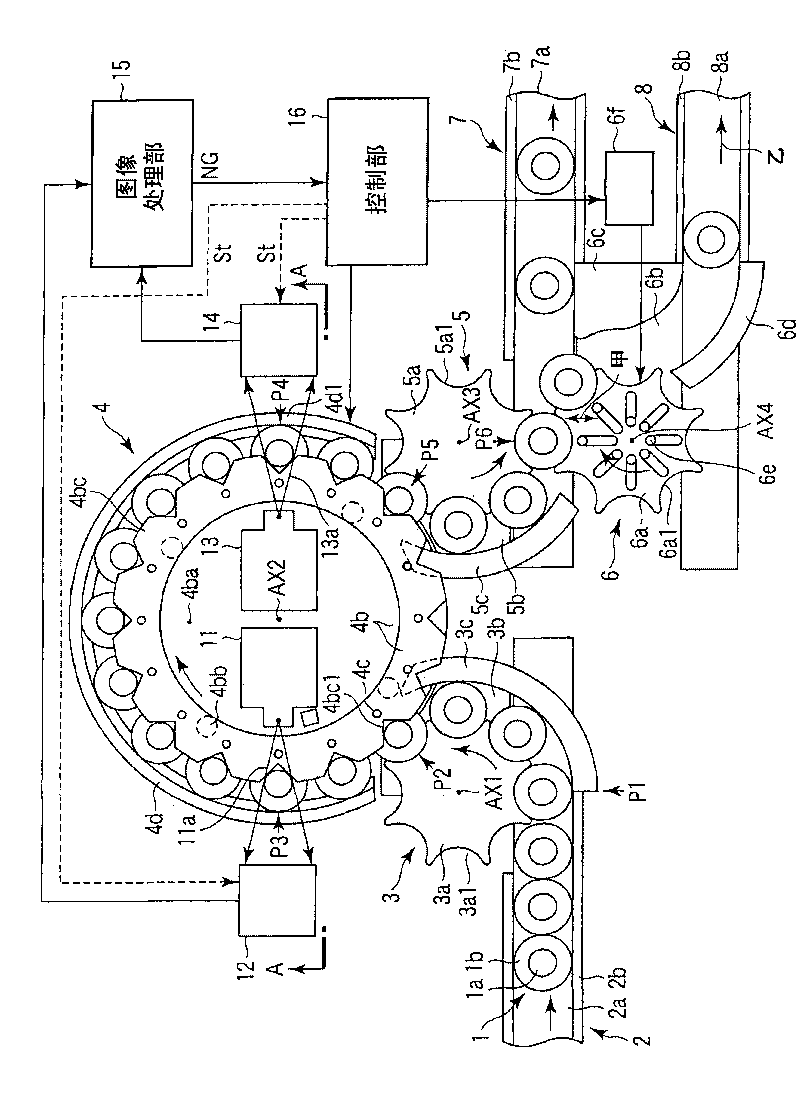

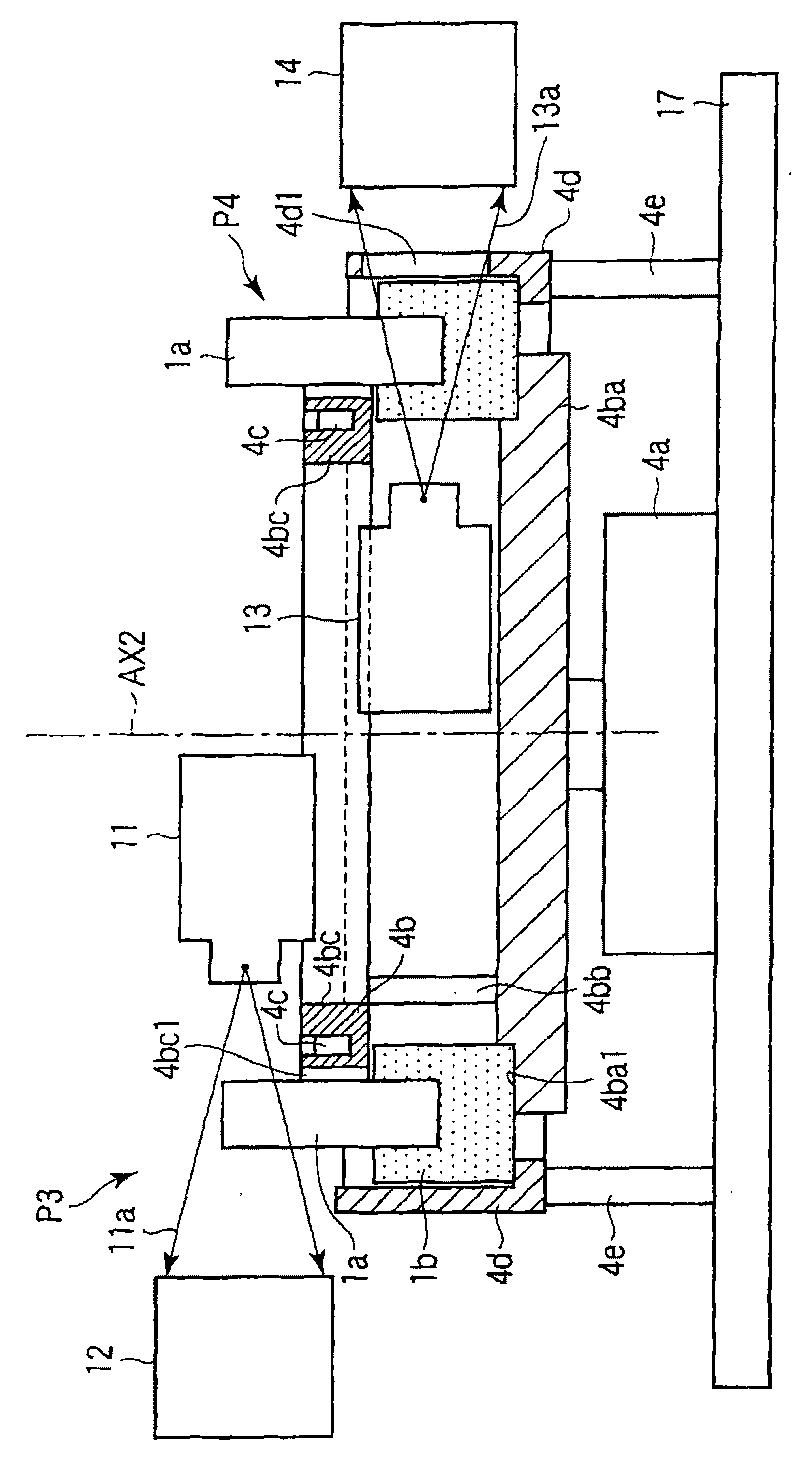

[0049] figure 1 and figure 2 is a composition diagram showing Embodiment 1 of the present invention, figure 1 is a top view, figure 2 yes figure 1 The A-A line shown is the sectional view.

[0050] The battery inspection device consists of a battery delivery system and a battery detection system.

[0051] The components of the battery conveying system include: conveying conveyor belt 2 for conveying batteries 1 in a specified direction, input mechanism 3, rotating conveying part 4, take-out mechanism 5, unqualified product take-out mechanism 6, qualified product conveying conveyor belt 7, and unqualified product conveying conveyor belt8.

[0052] The components of the battery inspection system include: the first X-ray source 11 and the first X-ray detector 12 for X-ray inspection on the upper side of the battery 1, the second X-ray source 13 and the first X-ray detector for X-ray inspection on the lower side of the battery 1 2. X-ray detector 14, image processing un...

Embodiment approach 2

[0133] Embodiment 2 (corresponding to claims 5 and 6)

[0134] Compared with Embodiment 1, Embodiment 2 differs in that the cylindrical table 4b is continuously rotated at a predetermined rotation speed and that X-ray detectors 12', 14' with shake correction functions are used instead of X-ray detectors 12, 14. The X-ray detectors 12', 14' with shake correction have a function of capturing a transmission image of a moving object without movement and shake.

[0135] Therefore, as Embodiment 2, except for the above two points, the configuration of Embodiment 1 can be applied as it is, so the description of the overall configuration of the battery inspection device will be omitted.

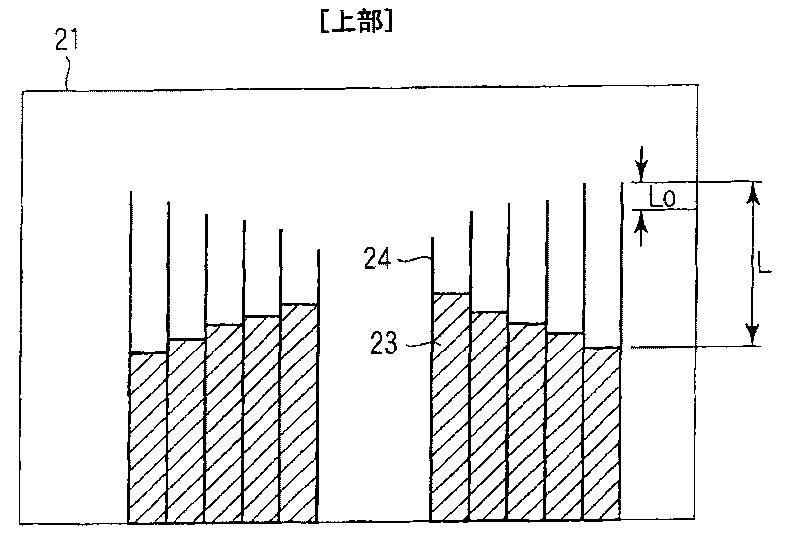

[0136] Figure 4 It is a configuration diagram (plan view) of the X-ray detectors 12', 14' with a shake correction function. Such X-ray detectors 12', 14' with shake correction are known from the laid-open publication (Japanese Unexamined Patent Publication No. 2003-114279).

[0137] Specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com