Automatic test device of flatness and thickness of metal sheet

An automatic detection device, metal sheet technology, applied in electromagnetic measurement device, electric/magnetic thickness measurement, electric/magnetic roughness/irregularity measurement, etc., can solve the problems of large human error, high price, slow test speed, etc. , to achieve the effect of convenient operation and maintenance, easy promotion and application, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment, but can not be regarded as the limitation of the present invention.

[0019] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

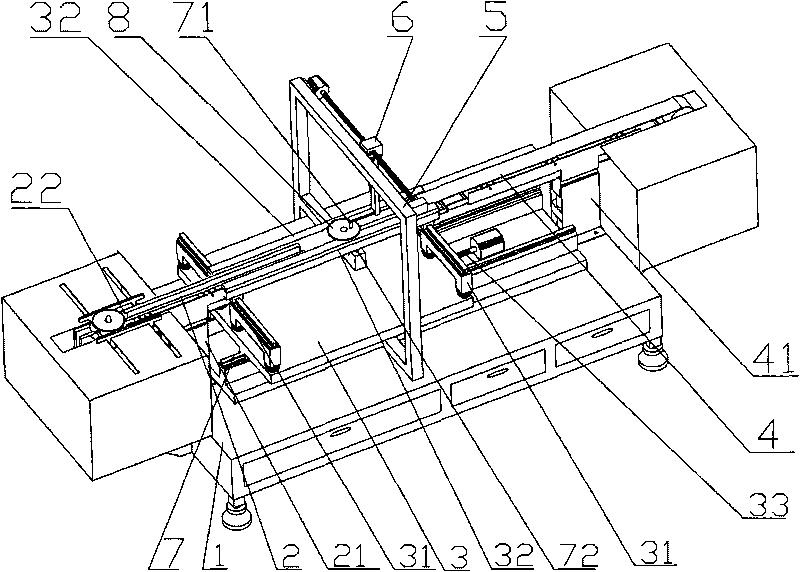

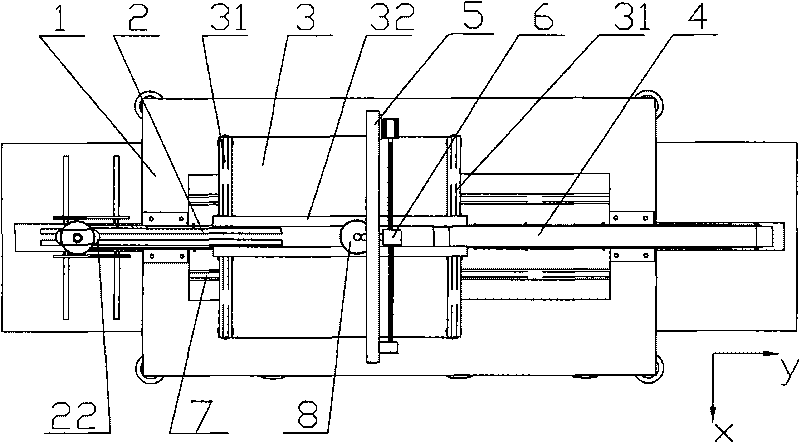

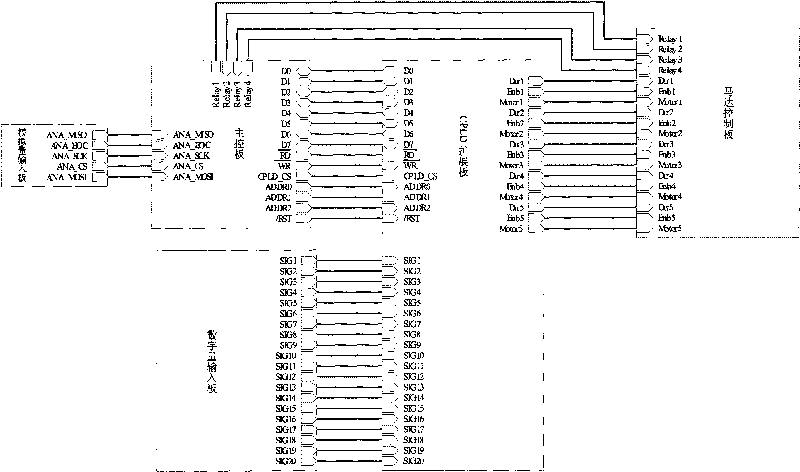

[0020] The automatic detection device for the flatness and thickness of the metal sheet includes a frame 1, a feeding mechanism 2, a detection platform, and a discharge mechanism 4. The frame and the detection platform are connected by a Y-direction track 7. The detection platform includes a detection frame 3. Guide rail 31, detection beam 32, cantilever fixing frame 5, cantilever 6, upper test probe 71, lower test probe 72, ball screw mechanism 33 and measurement circuit in the Y-axis direction, and the detection frame 3 is fixedly provided with two along the X-axis direction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com