Mechanical boiling bagasse drier

A dryer and boiling technology, used in drying solid materials, heating to dry solid materials, drying, etc., can solve problems such as dead bed, explosion, and unsatisfactory drying effect, and achieve the effect of improving thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be noted that the examples do not limit the protection scope of the present invention.

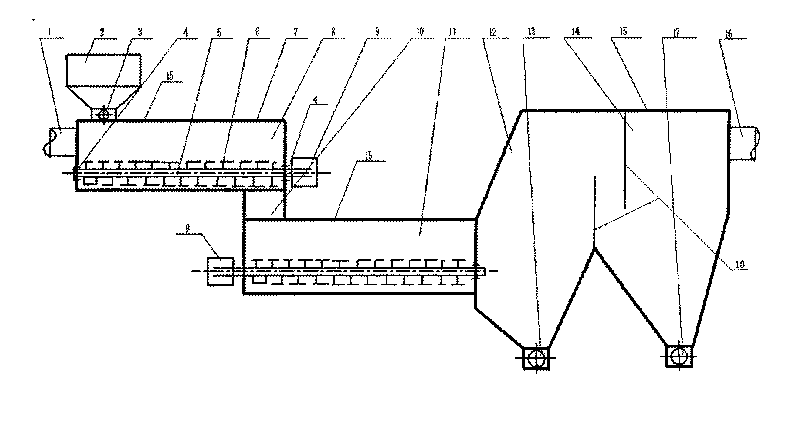

[0014] Such as figure 1 As shown, the appearance of the primary dryer 8 and the secondary dryer 11 is a long or arched box up and down, with a hopper 2 and a feeder 3 on the front and upper part of the box, and a throwing lifter inside the box. The throwing roller is composed of a shaft 5, a bearing 4 and a set of rake teeth 6. The throwing roller is connected with the power and transmission device 9. The dryer is connected in two stages. The outlet of the first stage dryer 8 is on the body Below or on both sides, the feed port of the second stage dryer 11 is docked by the connection port 10, and the discharge port of the second stage dryer 11 is connected with the feed port of the primary separation chamber 12; the separation chamber is a The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com