Device for drying fabric and method

A drying device and fabric technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of low production efficiency, poor drying quality, short service life, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

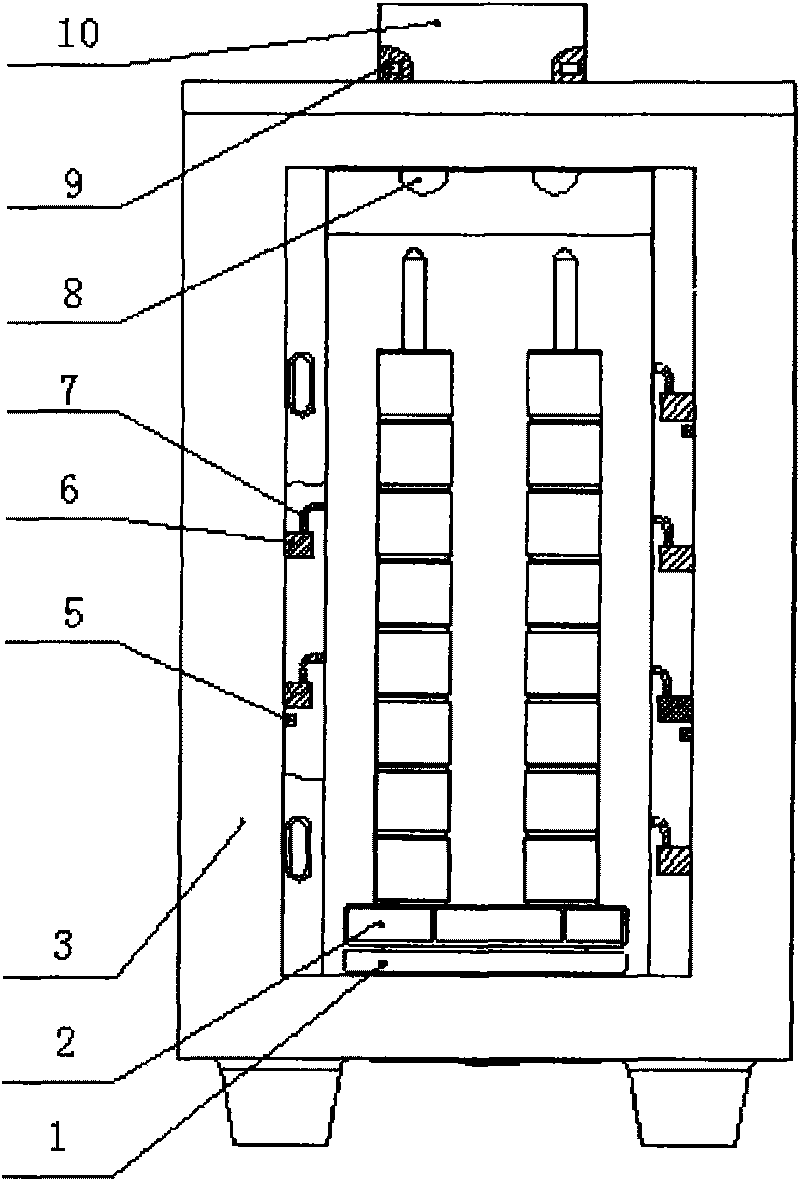

[0030] An embodiment of the present invention provides a fabric drying device, which is mainly composed of a roller table, a drying tray, box parts, an online detection system, and a PLC control system.

[0031] Wherein, the roller table traverses through the interior of the box body part, and is located above the bottom of the box body part, parallel to the bottom of the box body part; the drying tray is placed on the roller table, and follows the rolling of the roller table through the box body part, The on-line detection system is installed inside the box body, detects relevant data inside the box body in real time, and feeds back the relevant data to the PLC control system. The PLC control system is located outside the box body and can be operated manually or automatically.

[0032] The various components of the drying device are described in detail below:

[0033] (1) Roller table

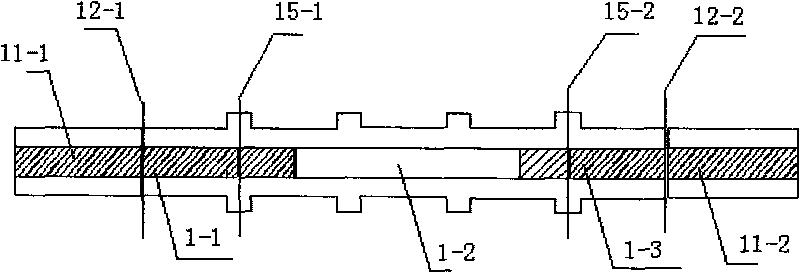

[0034] According to the physical structural characteristics of the roller table, the roll...

Embodiment 2

[0091] An embodiment of the present invention provides a fabric drying method using the fabric drying device in Example 1, comprising:

[0092] The fabrics are sequentially passed through a plurality of microwave-dried heating cabinets, and the drying power of these heating cabinets decreases one by one according to the passing order of the fabrics.

[0093] Further, the method also includes:

[0094] The fabric passes through the cooling transition box during the process from one heating box to another heating box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com