Device for continuous extrusion forming of copper waterstop on slope surfaces

A molding device, copper water-stop technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of manual packing of rubber rods, easy folding of copper water-stop flanges, etc., to save time, prevent edge overlap, reduce The effect of welding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

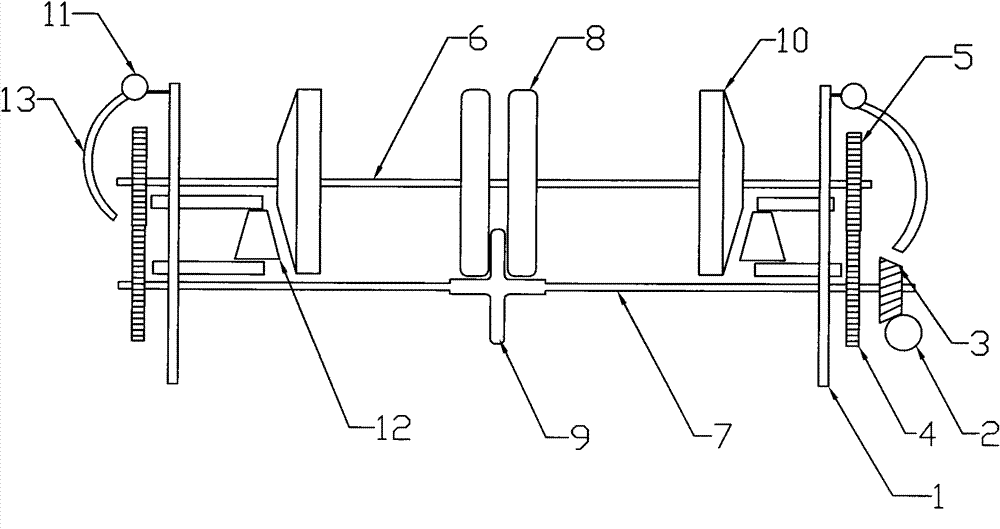

[0019] Such as figure 1 , 2 As shown, the extrusion device of the present invention includes a worktable 1, a driving system, an upper roller group, a lower roller group and a loading mechanism, and the driving system includes a motor, a sprocket, a transmission shaft 2, a worm wheel 3, a transmission wheel 4, and a driven wheel 5. The upper roller group includes upper rolling shaft 6, concave extrusion wheel 8, flange extrusion wheel 10, the lower roller group includes lower rolling shaft 7, cam 9 and passive conical wheel 12, and the loading mechanism includes push rod and tension spring.

[0020] Workbench 1 is a rectangular three-dimensional frame with side plates installed on both axial sides. The workbench is divided into front and rear parts in the axial direction. The front part is the initial pressing section, and the rear part is the forming section. end, the transmission shaft 2 is installed on the axial side of the workbench, and multiple rows of upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com