Prefabricated track slab combined track beam

A technology of track slabs and track beams, applied in the field of track beams, can solve the problems of high cost and high structural height, and achieve the effects of simple shape, reduced construction difficulty, and improved noise directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

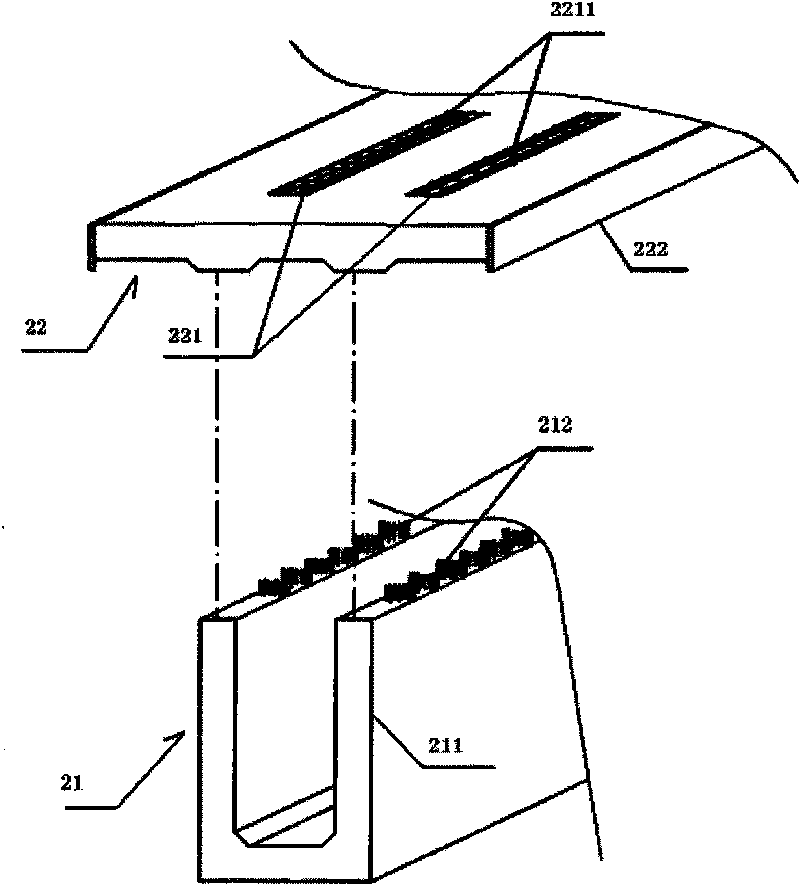

[0029] based on the following figure 2 and image 3 , to further illustrate the preferred embodiment of the present invention.

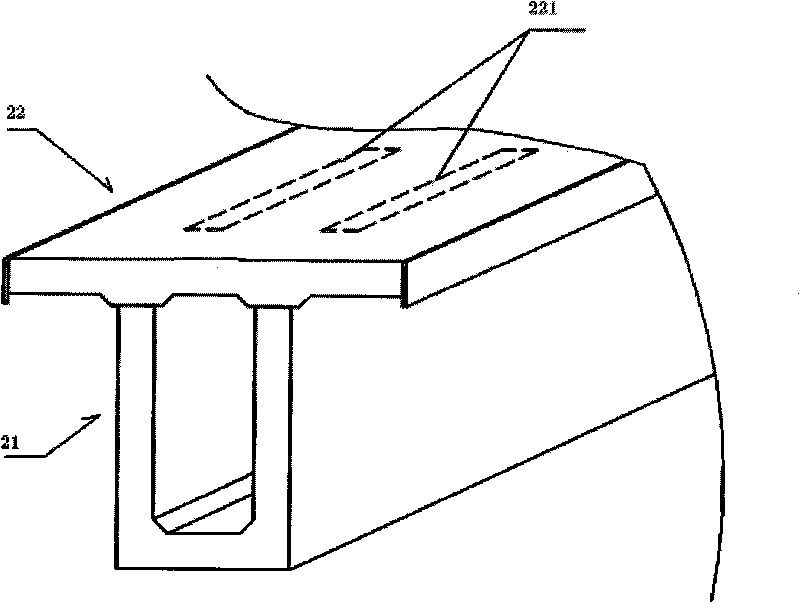

[0030] Such as figure 2 As shown, it is a prefabricated track slab combined with a track beam 20 of the present invention, the upper part of which is a prestressed track slab 22, and the lower part is a prestressed groove-shaped support beam 21. The two are post-cast by reinforced concrete, effectively combined into one structure, and jointly bear load.

[0031] Two notches 221 are reserved on the track plate 22 , and the grid-like steel bars 2211 are exposed in the notches 221 , and the positions of the notches 221 correspond to the positions of the support beam webs 211 . During pouring, a set of steel molds with adjustable cross slopes are made. The position of the embedded part of the track function area 222 and the position of the notch 221 of the track plate 22 are reserved on the mold, and a certain accuracy can be guaranteed. In the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com