Yellow and red ramie peeler

A kenaf peeling machine and technology of kenaf are applied in mechanical treatment, fiber mechanical separation, textile and papermaking, etc., and can solve the problems of low peeling efficiency, high peeling labor intensity, and poor peeling quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

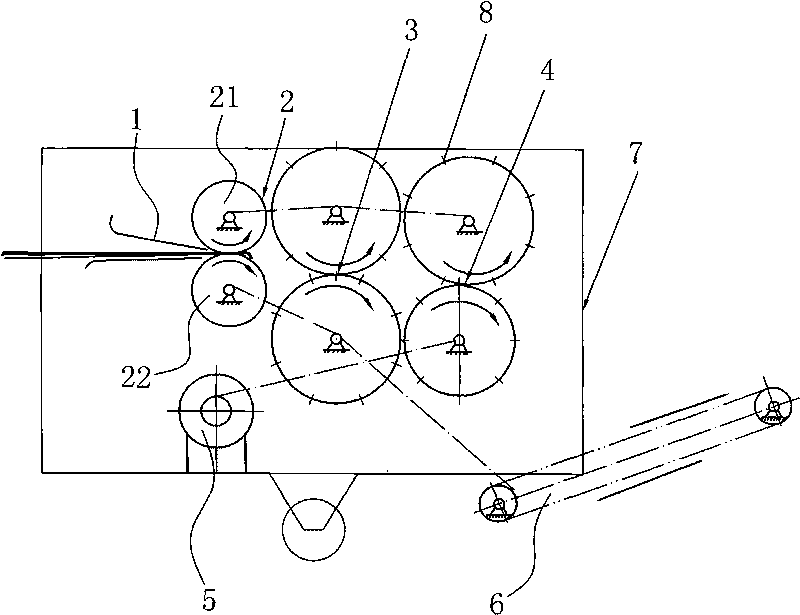

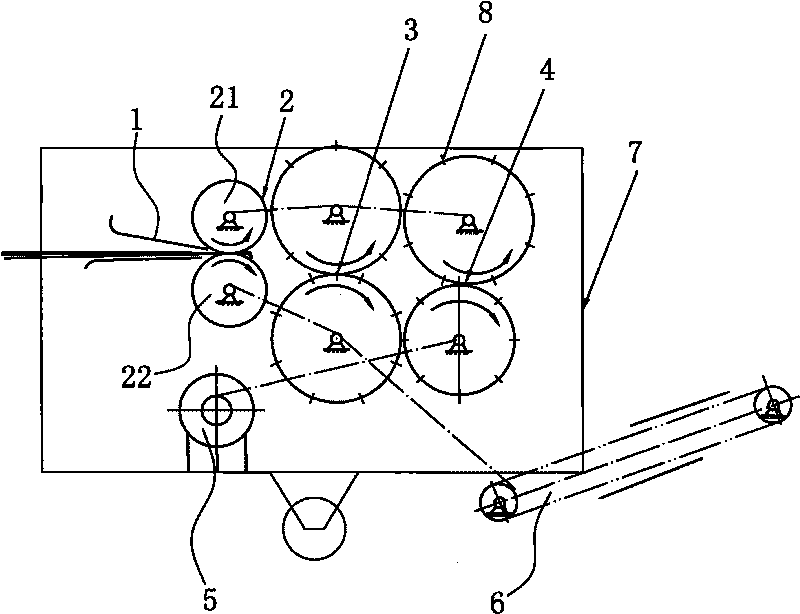

[0008] From figure 1 It can be seen that this yellow and kenaf peeling machine of the present invention comprises feeding hopper 1, pressure roller 2, first-level peeling cylinder 3, secondary peeling cylinder 4, power 5, hemp output belt 6 and frame 7, wherein The pressure roller 2 includes an upper pressure roller 21 and a lower pressure roller 22 with the same structure, and the power 5 uses an electric motor or a diesel engine to drive the pressure roller 2 and the peeling cylinder through a pulley. There are 8-10 pulsator teeth evenly distributed on the upper and lower pressure rollers, and the two-stage peeling cylinders have beating plates for scraping the fresh stems of yellow and kenaf to separate the skin and bones. The hemp output belt 6 is positioned at the below of the secondary peeling cylinder 4, and the hemp bark is sent outside the machine. There are wheels below the frame 7, which can be easily promoted. The inventor has found through repeated tests that wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com