Method for preparing cyhalothrin

A technology of cyhalothrin and chlorocyanamide trifluoride, which is applied in the field of preparation of pyrethroids, can solve the problems of reduced raw powder yield, low purity, black color, etc., and achieves reduced production costs, simple separation, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

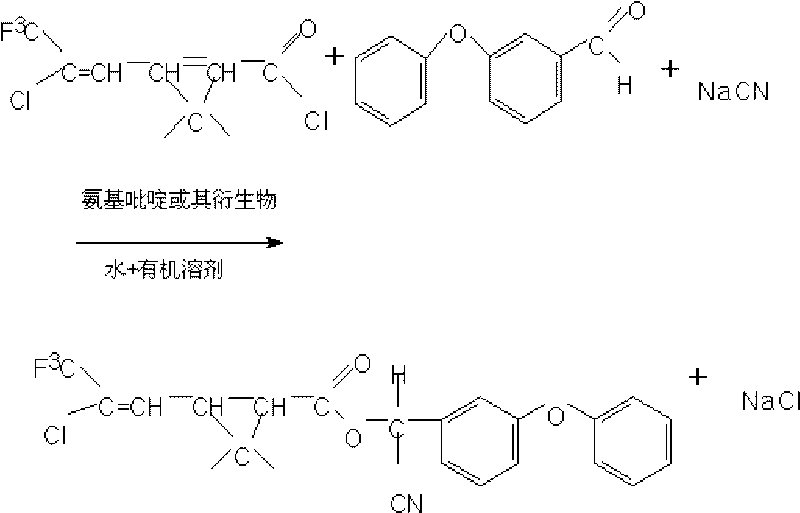

Image

Examples

Embodiment 1

[0019] The method for preparing cyhalothrin of the present embodiment has the following steps:

[0020] ① Prepare a mixed solution. 200kg purity is 99% ether aldehyde (1kmol), the concentration of 235.2kg is 25% sodium cyanide aqueous solution (1.2kmol), the toluene solvent of 800kg, the 2,2-dimethylaminopyridine of 200g mixes and obtains mixed solution .

[0021] ② Preparation of crude product containing cyhalothrin. By trifluorochlorocyanoyl chloride, step 1. ether aldehyde and sodium cyanide in the mixed solution as reactants, by step 1. 2,2-dimethylaminopyridine in the mixed solution is a catalyst, by step 1. the toluene in the mixed solution Carry out the following chemical reaction of generating cyhalothrin for the solvent: the 269kg purity that the preparation example gained is 97% chlorocyanoyl chloride (1kmol) dropwise in the above-mentioned mixed solution in 4h at the temperature of 17 ℃, then in Stirring at 20°C for 8 hours gave a crude product containing cyhalot...

Embodiment 2~ Embodiment 7

[0024] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0025] Table 1

[0026]

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com