Bone China and preparation method thereof

A technology of bone china and bone powder, applied in the field of bone china, to achieve the effect of improving mechanical strength and light transmittance, good fluidity, and solving the instability of slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

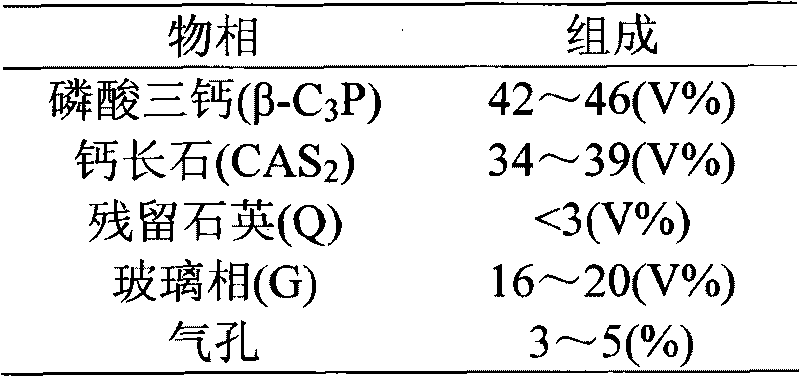

Image

Examples

Embodiment 1

[0033] The blank is prepared according to the following mass percentages, bone meal 42.45%; feldspar 14.15%; quartz 11.32%; clay 32.08%.

[0034] 1) After drying the bone meal in an oven at 70°C, according to the heating rate of 5°C / min, calcining at 1200°C for 1 hour, cooling with the furnace, ball milling to a particle size of 1-2 μm, washing with water, and drying as a follow-up experiment. Bone meal raw material.

[0035] 2) Clay is not ball-milled, feldspar is ball-milled to a particle size of 2-3 μm, and quartz is ball-milled to a particle size of 4-5 μm.

[0036] 3) The ingredients are weighed according to the mass percentage of the raw materials, and then put into the mill for wet ball milling, and 0.2% water glass and 0.075% sodium citrate composite debonding agent added with the total dry material are used as the dispersant of the bone china slurry. The grinding medium adopts zirconium balls, and the balls are graded: small balls account for 50%, medium balls accoun...

Embodiment 2

[0041] The blank is prepared according to the following mass percentages, bone meal 51.89%; feldspar 14.15%; quartz 9.43%; clay 24.53%.

[0042] 1) After drying the bone powder in an oven at 70°C, according to the heating rate of 5°C / min, calcining at 1200°C for 1 hour, cooling with the furnace, ball milling to a particle size of 2-3 μm, washing with water, and drying as a follow-up experiment. Bone meal raw material.

[0043] 2) Clay is not ball-milled, feldspar is ball-milled to a particle size of 4-5 μm, and quartz is ball-milled to a particle size of 5-6 μm.

[0044] 3) The ingredients are weighed according to the percentage of the raw materials, and then put into the mill for wet ball milling, and 0.2% water glass and 0.075% sodium citrate compound debonding agent added with the total dry material are used as the dispersant of the bone china slurry. The grinding medium adopts zirconium balls, and the balls are graded: small balls account for 50%, medium balls account for...

Embodiment 3

[0049] The blank is prepared according to the following mass percentages, bone meal 50.93%; feldspar 10.19%; quartz 11.11%; clay 27.78%.

[0050] 1) After drying the bone powder in an oven at 70°C, according to the heating rate of 5°C / min, calcining at 1200°C for 1 hour, then cooling with the furnace, ball milling to a particle size of 3-4 μm, washing with water and drying as a follow-up experiment. Bone meal raw material.

[0051] 2) Clay is not ball-milled, feldspar is ball-milled to a particle size of 3-4 μm, and quartz is ball-milled to a particle size of 8-9 μm.

[0052] 3) The ingredients are weighed according to the percentage of the raw materials, and then put into the mill for wet ball milling, and 0.2% water glass and 0.075% sodium citrate compound debonding agent added with the total dry material are used as the dispersant of the bone china slurry. The grinding medium adopts zirconium balls, and the balls are graded: small balls account for 50%, medium balls accoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com