Mine single-rope hoisting balance wheel brake rope anti-case-crashing device

A single-rope hoisting and balancing wheel technology, which is used in mine lifting equipment, elevators, transportation and packaging, etc., can solve the problem that the braking force of the steel rope spiral buffer is difficult to accurately calibrate, the deceleration is large, and the occupant's health is damaged and the system is affected. problems such as deformation resistance of moving wire ropes, to achieve ideal safety protection performance, long braking distance, and small investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

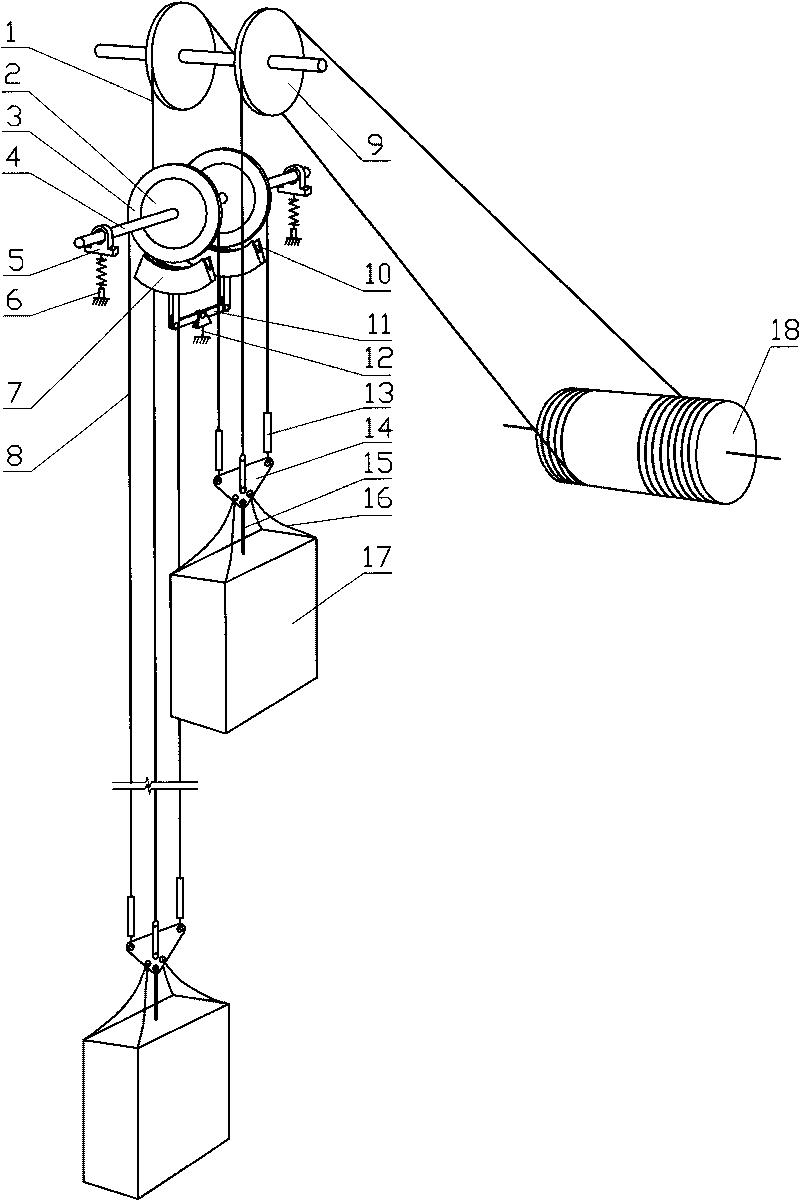

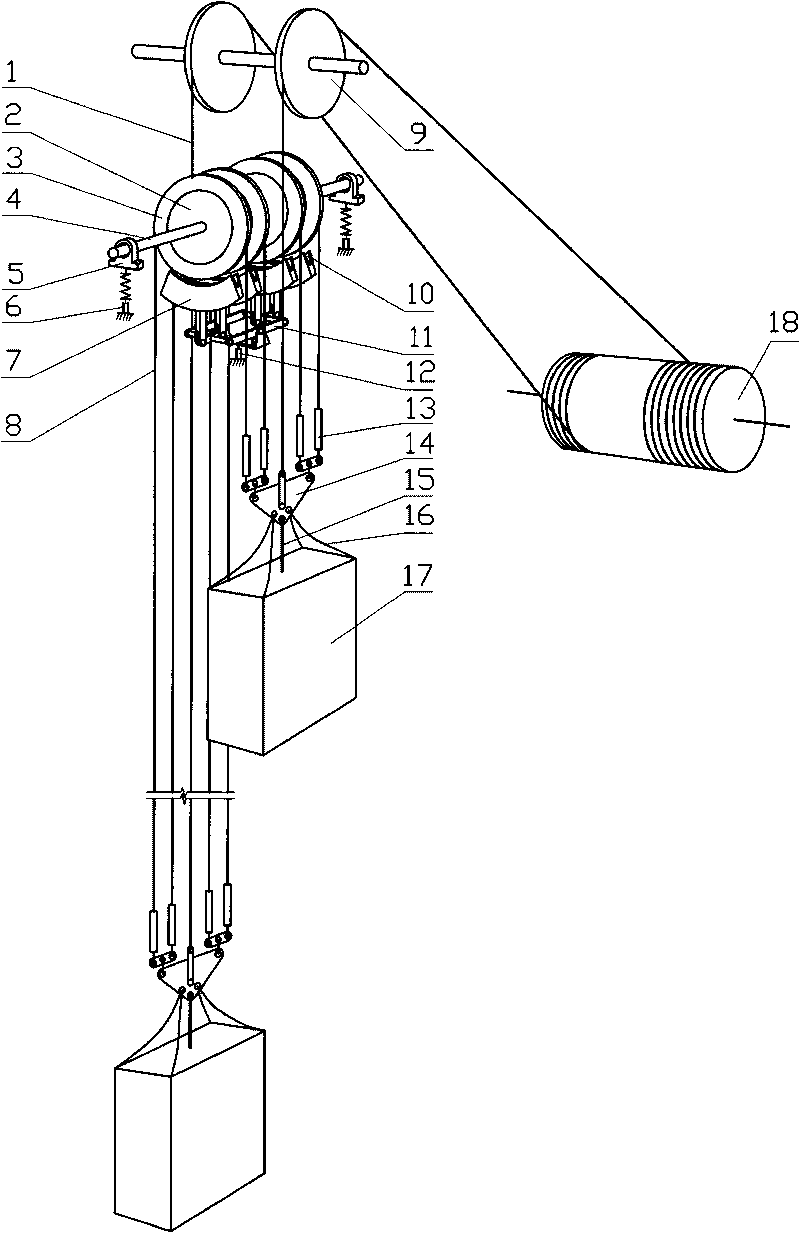

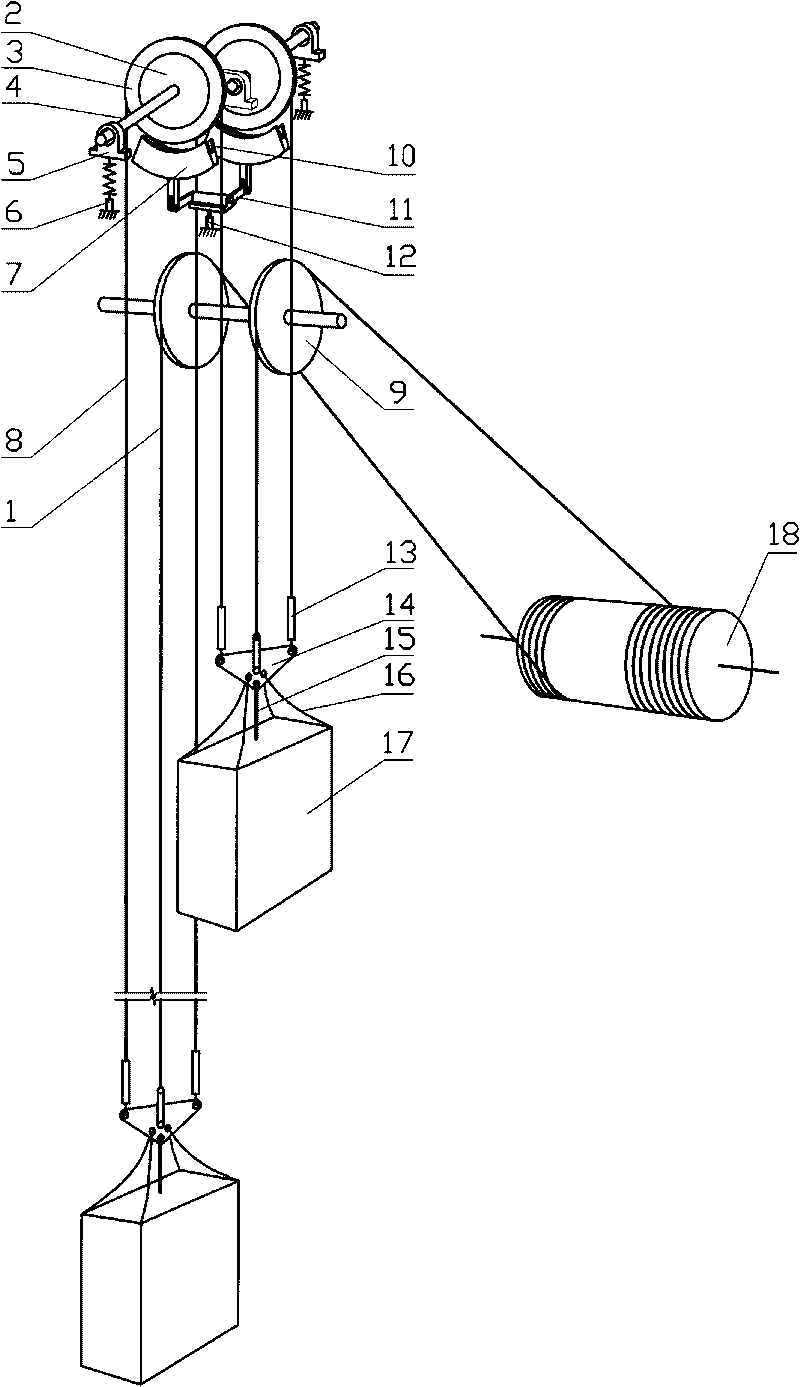

[0040] as attached figure 1 As shown, the balance wheel braking rope anti-fall tank device of the present invention is composed of a balance wheel 2, a balance wheel shaft 4, an elastic bearing device 5, a brake brake 7, a brake rope 8, a lifting connection device 14, etc.; the balance wheel 2 is provided with Two, two brake ropes 8 are suspended on the two balance wheels 2, and the two brake ropes 8 are formed on the same side on both sides of the balance wheel 2, and are respectively lifted in the lifting container 17 and the balance by the lifting connection device 14. The container 19 is connected in parallel with the lifting rope 1, and the lifting connection device 14 is a triangular cross-arm type; two lifting ropes 1 are respectively forwardly and reversely wound on the hoist drum 18; the balancing lifting container 19 can also be a counterweight; The wheel 2 is installed on the balance wheel shaft 4, and the balance wheel 2 can rotate freely on the balance wheel shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com