Rail-bound heavy-load carrier vehicle adopting non-contact power supply technology

A non-contact, transportation vehicle technology, applied in the direction of transportation of passenger cars, electric locomotives, transportation and packaging, etc., to achieve the effect of convenient factory design, convenient layout of general layout, and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

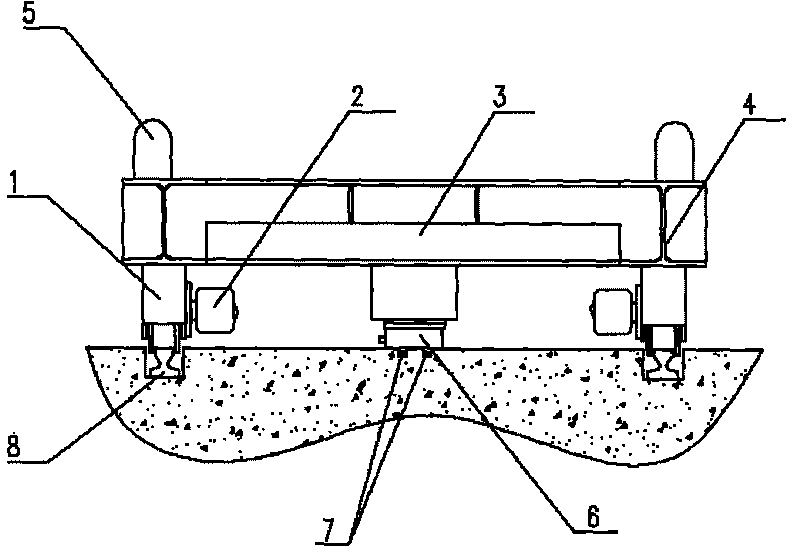

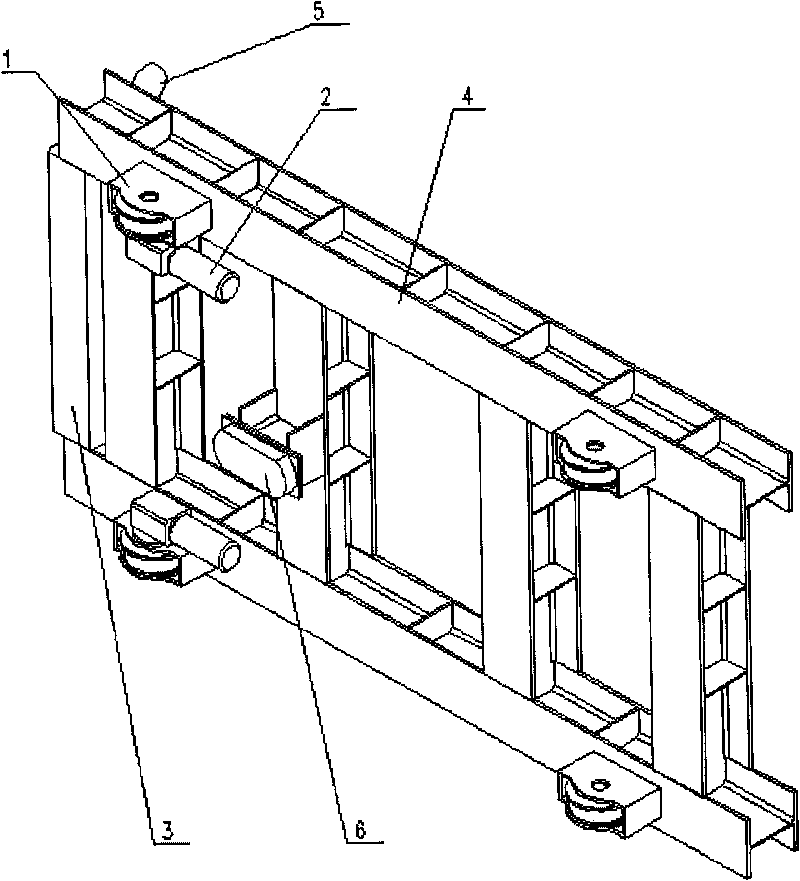

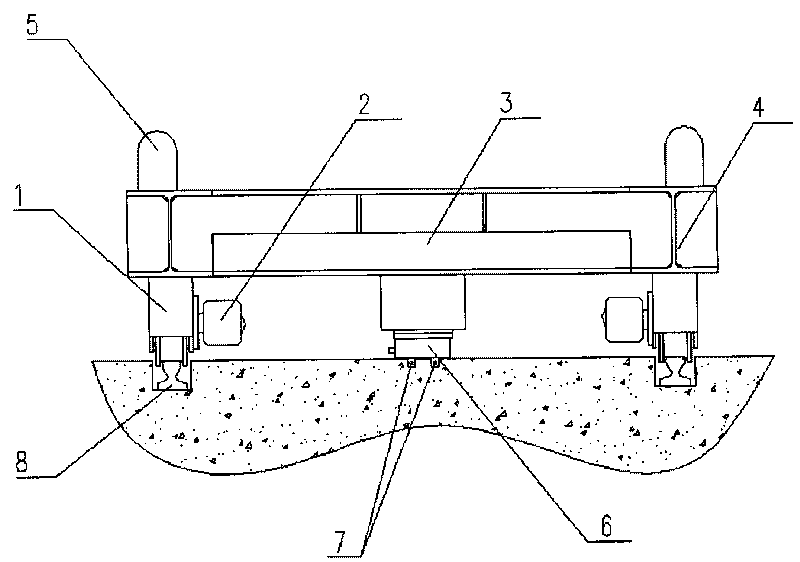

[0012] Such as figure 1 As shown, two gear motors 2 drive the moving cassette integrated wheel 1 to realize walking on the rail 8, and the gear motor 2 realizes the turning of the trolley through differential speed control.

[0013] Two cables 7 buried under the ground provide electromagnetic energy, which is converted into electric energy by the pick-up device 6 through electromagnetic induction to supply power to the electric point on the car.

[0014] The structure of the car body 4 is welded with section steel, and the ribs are welded on the section steel to strengthen the strength of the car body. The car body adopts a symmetrical structure, so that the whole car body can evenly transfer the weight of the goods to the box-type integrated wheel 1 .

[0015] An audible and visual alarm device 5 is installed on the car body; an anti-collision device 3 is arranged in the forward direction of the car.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com