Marking method of material strips and compact type full-automatic IC (integrated circuit) material strip laser marking machine

A laser marking machine, laser marking technology, applied in the direction of conveyor objects, printing, electrical components, etc., to achieve the effect of improving efficiency and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

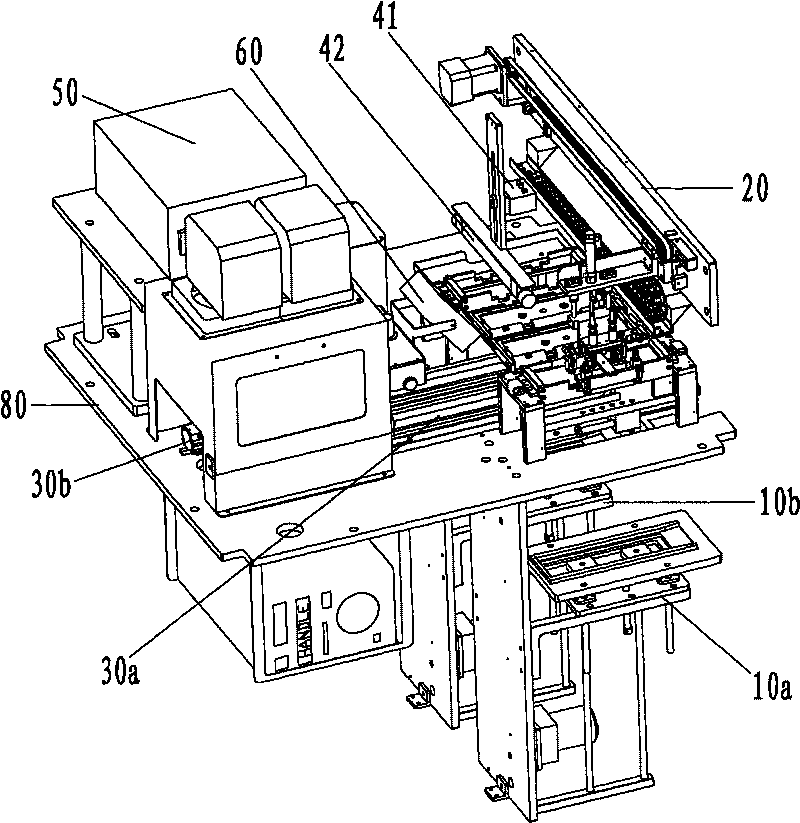

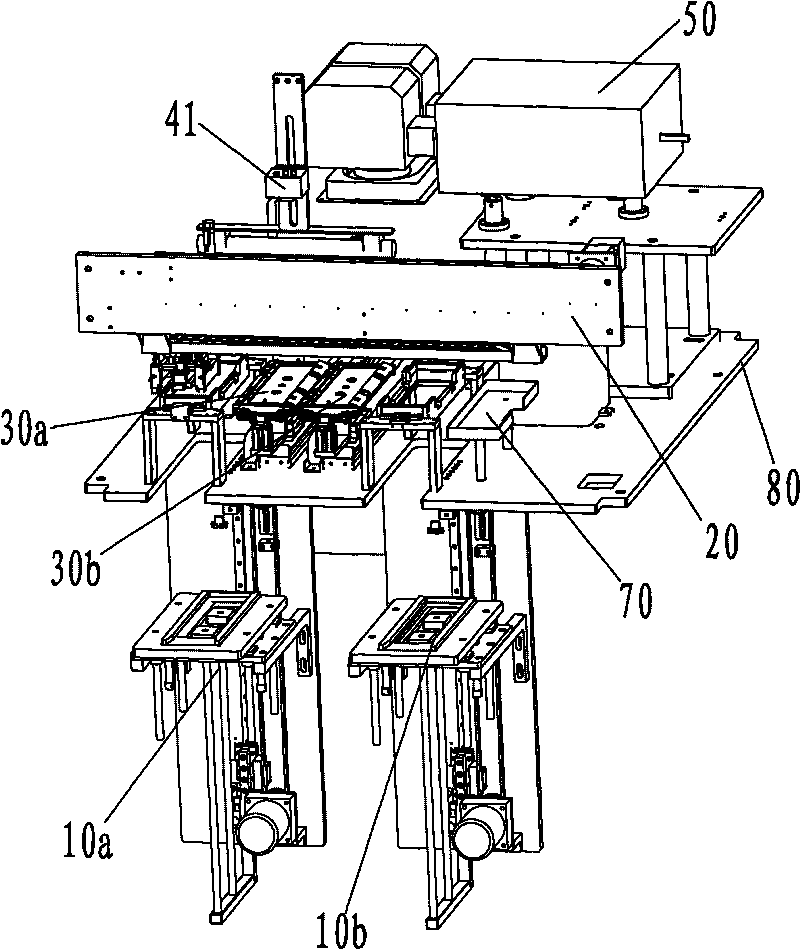

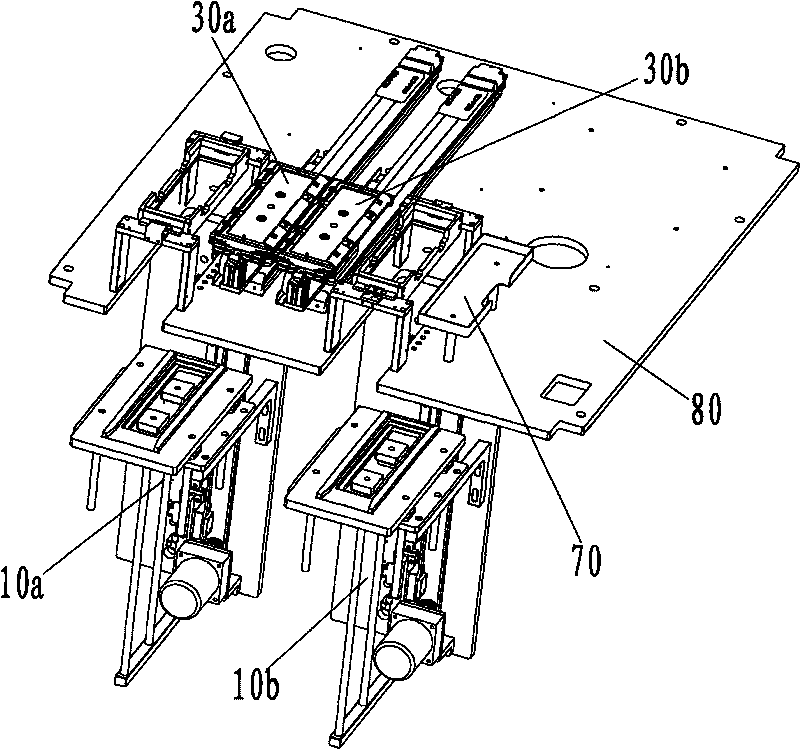

[0040] The compact automatic laser marking machine of the present invention is as figure 1 , 2 As shown in and 3, it includes an installation table panel 80, and a double-channel material ship material strip conveying device is installed on the installation table panel 80. Strip conveying device 30a and the second runner material boat material strip conveying device 30b; the two sides of the first runner material boat material strip conveying device 30a and the second runner material boat material strip conveying device 30b are respectively equipped with material strip lifting devices 10a and the strip descending device 10b; the outside of the strip descending device 10b is provided with a defective product box 70 installed on the installation table panel 80; Right above the device 10a, the strip descending device 10b and the defective product box 70, the pick-and-place h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com