Clean smoke gas fogging method and device of wet method smoke gas desulfuration system for thermal power plant

A wet flue gas desulfurization and flue gas purification technology is applied to the wet flue gas desulfurization system of thermal power plants to purify flue gas condensate mist and simulate acid condensation in the tail chimney of wet desulfurization, which can solve problems such as difficulty in condensing liquid, To achieve the effect of simple operation, accurate fog condensation results, and easy access to fog condensation devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

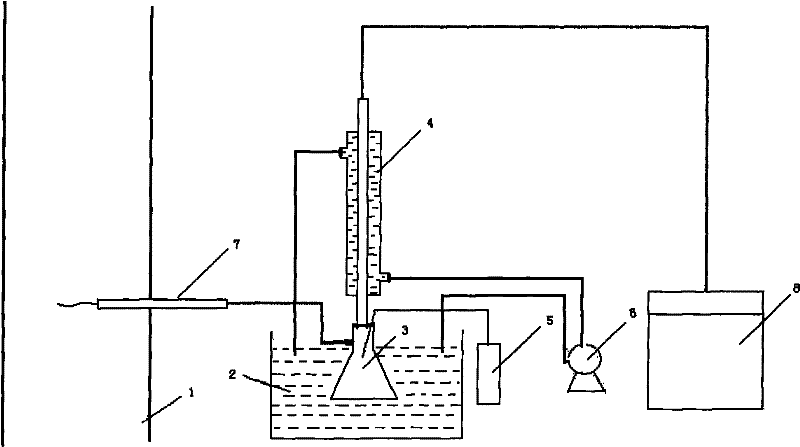

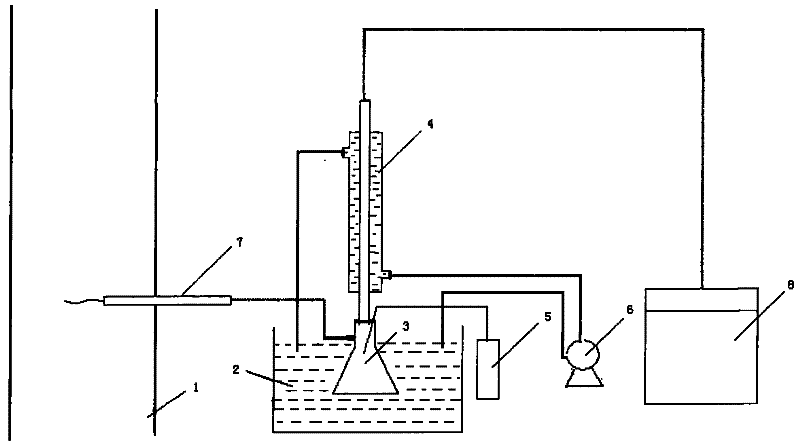

[0036] A device for cleaning flue gas and condensing fog in a wet flue gas desulfurization system of a thermal power plant. Sampler8.

[0037] Its connection mode is divided into gas path connection and water path connection.

[0038] For gas connection: connect the outlet end of the sampling gun with the side port of the filter bottle 3 and seal it; the upper port of the filter bottle 3 is connected with the lower port of the inner tube of the condenser tube 4 and seal it, and place the filter bottle 3 at a constant temperature The water bath 2 contains a hygrometer 5, and the upper opening of the inner tube of the condenser tube 4 communicates with the sampler 8 and seals it. The flue gas enters the side port of the filter bottle through the sampling gun, enters the inner tube of the condenser tube from the upper port, enters the flue gas sampler through the upper port of the inner tube of the condenser tube, and flows out from the exhaust port of the sampler.

[0039] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com