Method and device for simultaneous desulphurization and denitration by flue gas-seawater method

A desulfurization and denitrification, seawater technology, applied in separation methods, chemical instruments and methods, climate sustainability, etc., can solve problems such as secondary pollution, high construction and operation costs, complex processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

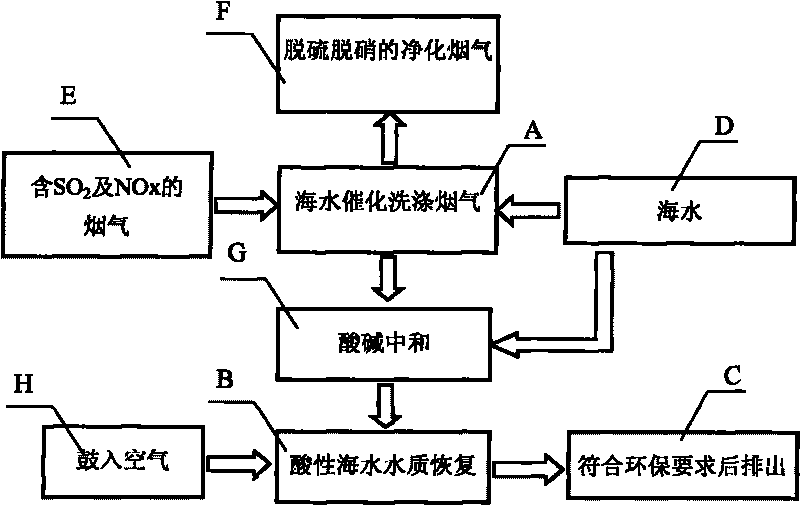

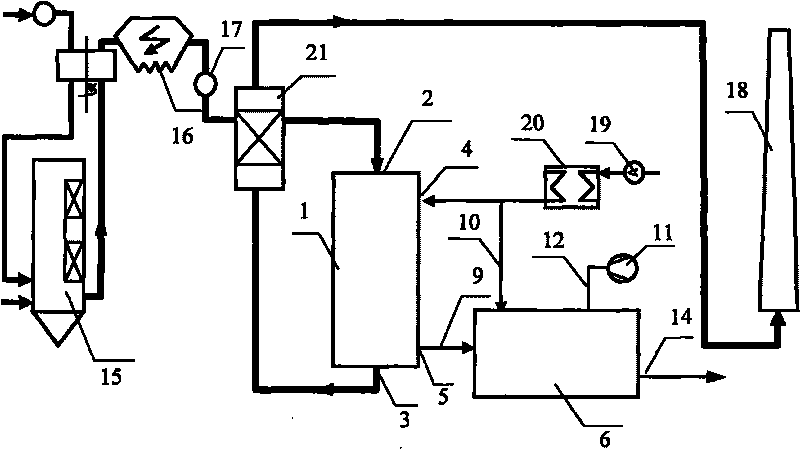

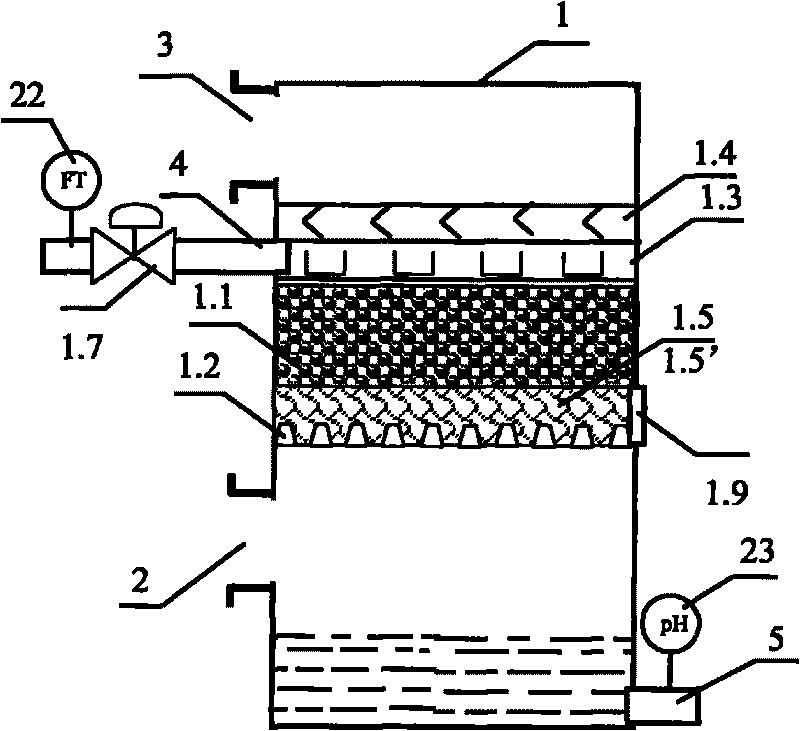

[0050] like figure 1 Shown is a schematic diagram of the steps of the simultaneous desulfurization and denitrification method of flue gas and seawater method of the present invention, figure 2 It is the process program of the present invention applied in thermal power plants; the steps of the method for simultaneous desulfurization and denitrification of flue gas by seawater method in this embodiment are: A) seawater catalytic cleaning flue gas: use seawater to contain SO 2 and NOx flue gas for catalytic scrubbing to remove SO in the flue gas 2 and NOx, and then discharge the purified flue gas through simultaneous desulfurization and denitrification and discharge the acidic seawater formed in the washing process; the catalytic washing of the present invention is iron catalytic washing with seawater having or adding a certain amount of iron ions, or / and Make seawater or / and flue gas go through magnetic catalytic washing with an additional magnetic field. As far as this embodi...

Embodiment 2

[0063] What is different from the above-mentioned embodiment 1 is that the iron catalytic washing carried out with seawater is to add iron ions through a device that can add iron-containing solution during washing; the main parameters of this embodiment are:

[0064] Flue gas volume 1,100,000Nm 3 / h

[0065] Raw flue gas SO 2 Concentration 1900mg / Nm 3 , NOx concentration 650mg / Nm 3

[0066] Alkaline-acid ratio of washed seawater flue gas 1

[0067] The concentration of iron ion after washing seawater is 106μg / kg

[0068] Clean flue gas SO 2 76mg / Nm 3 , NOx 380mg / Nm 3

[0069] Sea water quality recovery device drainage pH > 6.8

[0070] Drainage COD increment <0.5mg / l

Embodiment 3

[0072] The difference from the above-mentioned embodiments is that the iron catalytic washing is a method in which a metal with lower electrochemical activity than iron is used as a cathode to make part of the iron material in the washing environment become a sacrificial anode to release iron ions; this implementation For example, the main parameters are: flue gas volume 2,100,000Nm 3 / h

[0073] Raw flue gas SO 2 1680mg / Nm 3 , NOx 580mg / Nm 3

[0074] The alkali-acid ratio of the washed seawater flue gas is 200

[0075] Washing seawater iron ion concentration 300μg / kg

[0076] Clean flue gas SO 2 80mg / Nm 3 , NOx 180mg / Nm 3

[0077] Sea water quality recovery device drainage pH > 6.8

[0078] Drainage COD increment <4.3mg / l

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com