Health protection rust preventing energy-saving quick-fried pan

A technology of stir-frying and health care, which is applied to frying pans, cooking utensils, special materials, cooking utensils, etc., and can solve the problems of wasting raw materials, low content, and unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

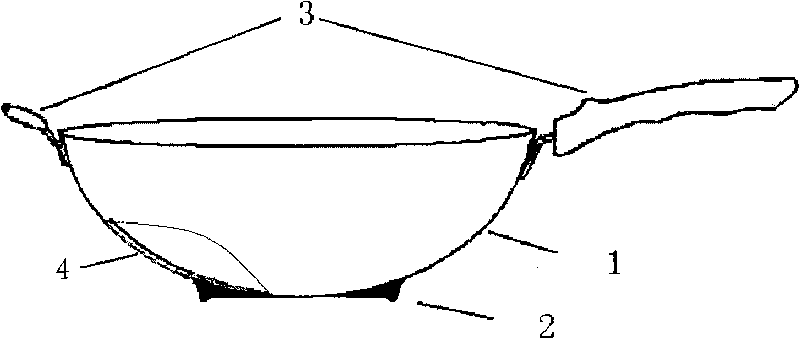

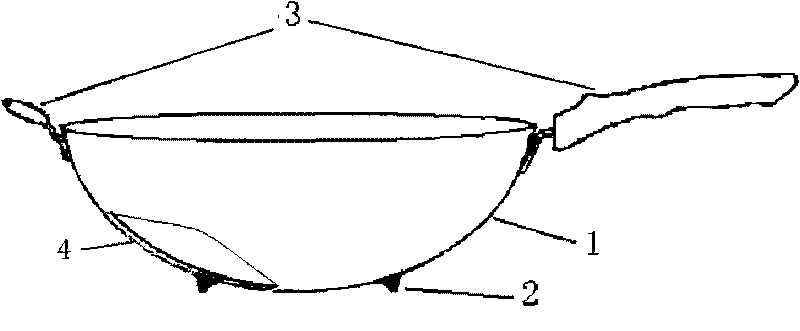

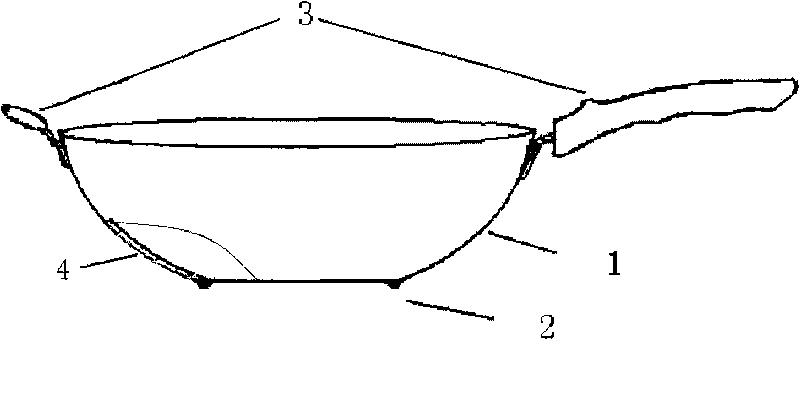

[0011] 1. Use 0.5---2.0mm stainless steel or refined iron according to figure 1 , figure 2 , image 3 As shown, the outer layer of the pot (or the pot blank obtained in Embodiment 1) is obtained by stamping or die-casting with a mold, and the inner surface is cut and processed according to the needs of the second step so as to fix and implement the second step. The special shape of the component aluminum alloy layer.

[0012] 2. The outer surface is covered with an enamel (ceramic) porcelain layer for sintering.

[0013] 3. Melt zinc-tin-selenium alloy or directly add zinc-selenium into aluminum or aluminum alloy in an appropriate proportion to obtain a multi-component aluminum alloy melt, and then inject it into the mold to cover the inner layer of the outer layer of the pot obtained in the first step On the surface, a pan is obtained.

[0014] 4. Cut the pot billet, drill holes, and install the handle.

[0015] The pan provided by the invention is suitable for various ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com