Positive electrode material of alkali dry battery and preparation method thereof and alkali dry battery

A positive electrode material and dry battery technology, applied in the direction of battery electrodes, primary battery electrodes, circuits, etc., can solve the problems that cannot meet the requirements of digital cameras well, and the performance of high-current and high-power pulses is not satisfactory, and achieve a large improvement. Current constant power discharge performance, improved high power discharge performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

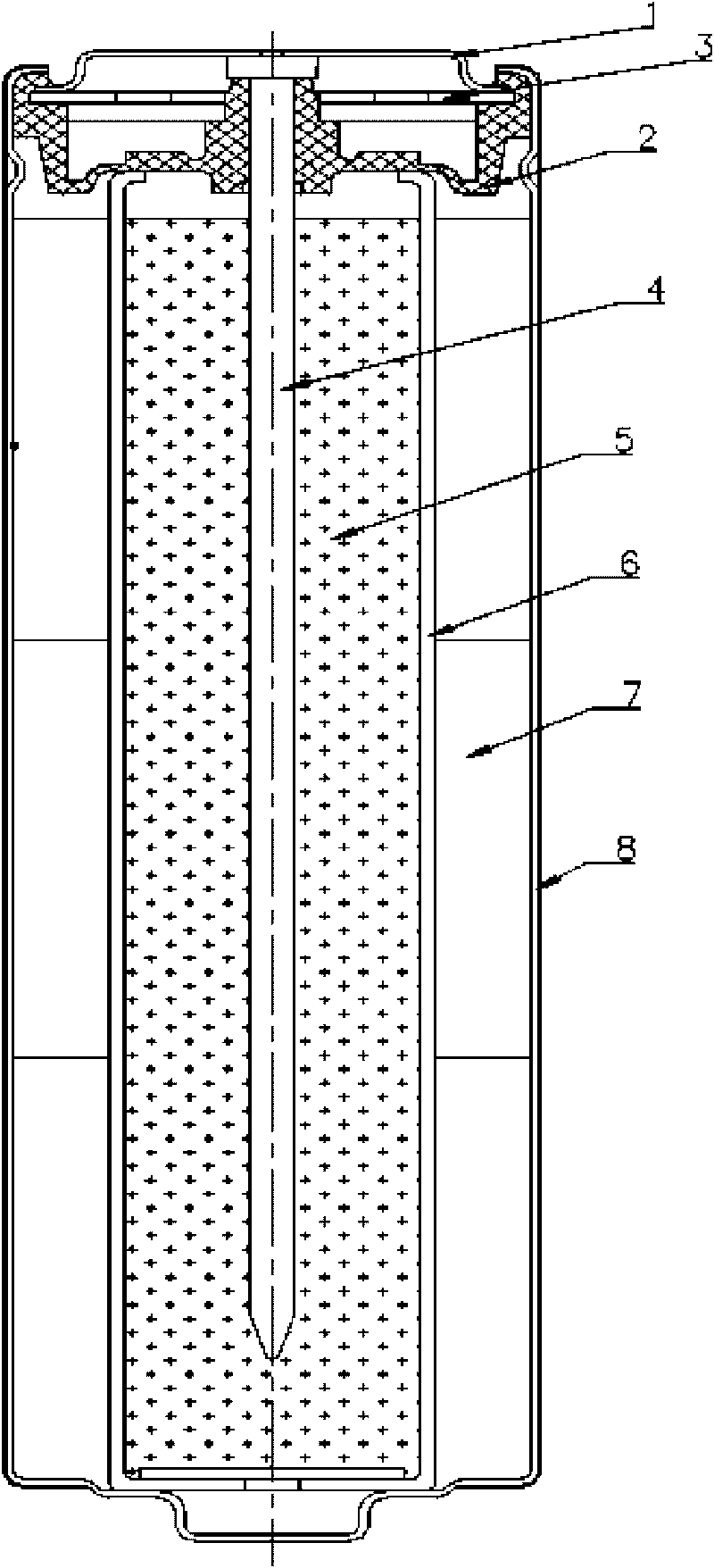

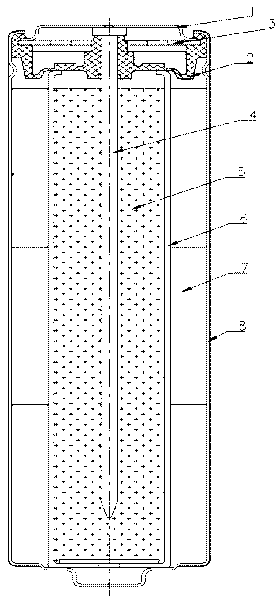

Image

Examples

Embodiment 1

[0025] Preparation and discharge performance test of embodiment 1 common alkaline dry battery

[0026] Fully mix the active ingredient manganese dioxide and conductive graphite at a weight ratio of 120:4~8, then add 3.5% alkaline electrolyte (KOH or NaOH), stir evenly and use 140~280kgf / cm 2 Tablets are pressed under a certain pressure, and then granulated and sieved to form positive electrode particles with a certain particle size distribution. Then, 0.1-0.3% of stearic acid additive is added to the positive electrode particles, and the positive electrode ring is formed by molding. ; First mix sodium polyacrylate and indium compound at a ratio of 40-60:1, and then add it to the alkaline electrolyte (in which the concentration of KOH is 32-42%, and the content of zinc oxide in the negative electrode is 1-5%) to obtain the condensate Colloidal electrolyte solution, then vacuumize and stir zinc powder and gel electrolyte solution at a ratio of 300:130-180, and the obtained collo...

Embodiment 2

[0030] Embodiment 2 Preparation and discharge performance test of alkaline dry battery of the present invention

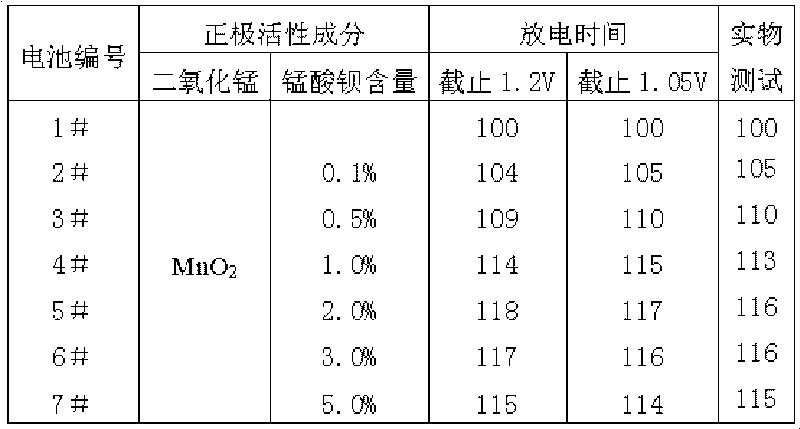

[0031] A two-component mixed substance composed of barium manganate and manganese dioxide is used to replace the manganese dioxide in Example 1 as the positive electrode active component of the alkaline dry battery, wherein the barium manganate addition is 0.1% of the positive electrode active component, according to the embodiment The method of 1 is used to make the positive electrode ring, and the negative electrode zinc paste to form the alkaline dry battery 2#.

[0032] Perform constant power discharge on 2# alkaline dry battery, and discharge items shall be carried out according to 7.1.5 of the IEC60086-2-2006 standard.

[0033] In a constant temperature environment of 20°C±2°C, take 9 2# batteries and perform 10 cycles of pulse discharge every 1 hour until the closed-circuit voltage drops to 1.05V; the pulse discharge is repeated at a constant power of 1500mW...

Embodiment 3

[0034] Embodiment 3 Preparation and discharge performance test of alkaline dry battery of the present invention

[0035] A two-component mixed substance composed of barium manganate and manganese dioxide is used to replace the manganese dioxide in Example 1 as the positive electrode active component of the alkaline dry battery, wherein the barium manganate addition is 0.5% of the positive electrode active component, according to the embodiment 1 method to make positive ring, and negative zinc paste to form alkaline dry battery 3#.

[0036] Perform constant power discharge on the 3# alkaline dry battery, and the discharge items shall be carried out in accordance with the provisions of 7.1.5 in the IEC60086-2-2006 standard.

[0037] In a constant temperature environment of 20°C±2°C, take 9 3# batteries and perform 10 cycles of pulse discharge every 1 hour until the closed circuit voltage drops to 1.05V; the pulse discharge is repeated at a constant power of 1500mW A cycle of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com