Device for measuring breakthrough sulphur capacity and using method thereof

A technology of sulfur capacity and hydrogen sulfide, which is applied in the direction of chemical analysis by precipitation, can solve the problems of reducing the accuracy of measurement results, complicated operation, etc., and achieves the effect of mild operating conditions, simple measurement process, and simplified measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

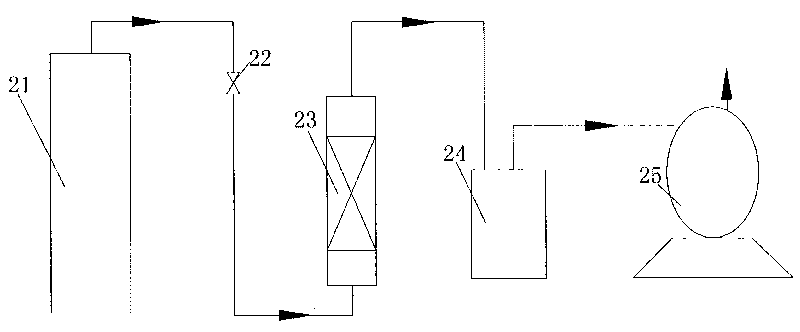

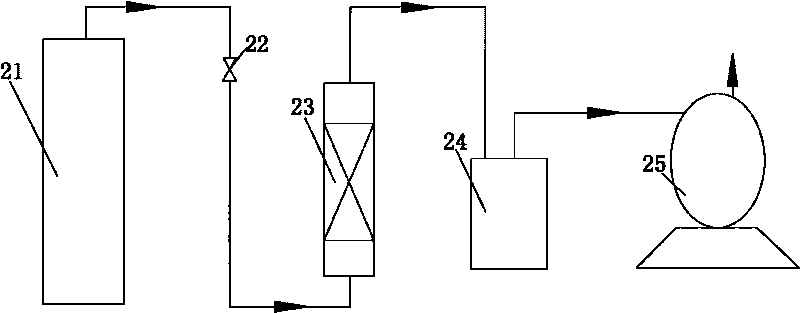

[0051] Weigh 1.0g (accurate to 0.001g), approximately 160 mesh JX-1 type desulfurizer sample, then fill the desulfurizer into the glass reactor 23 and ensure that the filling is uniform and compacted, and the desulfurizer particles after filling The aspect ratio in the reactor 23 is about 4, and then the two ends of the reactor are filled with cotton, and then the reactor 23, the mixed gas cylinder 21 containing hydrogen sulfide, and the needle-type The valve 22, the hydrogen sulfide detector 24 and the wet gas flow meter 25 are connected through pipelines and ensure airtightness. Wherein the concentration of the silver nitrate solution in the hydrogen sulfide detector 24 is 0.01mol / L. The volume content of hydrogen sulfide in the mixed gas provided by steel cylinder 21 is 3.8%.

[0052] Open the valve of steel cylinder 21 and adjust the outlet pressure to 0.2Mpa, open the needle valve 22 and control the airspeed to 200h -1 , the wet gas flow meter 25 starts to record data. ...

Embodiment 2

[0054] Weigh 1.0g (accurate to 0.001g), about 120 mesh JX-3C type desulfurizer sample, then fill the desulfurizer into the glass reactor 23 and ensure that the filling is uniform and compacted, and the desulfurizer particles after filling The aspect ratio in the reactor 23 is about 6, and the two ends of the reactor are filled with chemical fiber cotton, and then the reactor 23, the mixed gas delivery pipeline 21 containing hydrogen sulfide are provided according to the order of each part in the device. The rotameter 22, the hydrogen sulfide detector 24 and the wet gas flowmeter 25 are connected through pipelines to ensure airtightness. Wherein the concentration of the silver nitrate solution in the hydrogen sulfide detector 24 is 0.1mol / L. The volume content of hydrogen sulfide in the mixed gas provided by the mixed gas delivery pipeline 21 is 4.0%.

[0055] Open the valve of the mixed gas delivery pipeline 21 and adjust the outlet pressure to 0.2Mpa, open the needle valve o...

Embodiment 3

[0057] Weigh 1.0g (accurate to 0.001g), about 100 mesh 4D-1 type desulfurizer samples, then fill the desulfurizer into the glass reactor 23 and ensure that the filling is uniform and compacted, and the desulfurizer particles after filling The height-to-diameter ratio in the reactor 23 is about 5, and then the two ends of the reactor are filled with hemp fiber, and then the reactor 23, the mixed gas cylinder 21 that contains hydrogen sulfide, and the rotor are provided according to the order of each part in the device. The flowmeter 22, the hydrogen sulfide detector 24 and the wet gas flowmeter 25 are connected through pipelines and ensure airtightness. Wherein the concentration of the silver nitrate solution in the hydrogen sulfide detector 24 is 0.05mol / L. The volume content of hydrogen sulfide in the mixed gas provided by steel cylinder 21 is 4.2%.

[0058] Open the valve of steel cylinder 21 and adjust the outlet pressure to 0.2Mpa, the needle valve 22 and control the airs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com