Online metering device and method for automatically determining misalignment

A technology of automatic judgment and metering devices, which is applied to measuring devices, automatic recalibration, testing/calibration devices, etc., can solve the problems of unavailable, inaccurate, difficult to accurately judge measuring sensors, etc., to achieve convenient use, save manpower, The effect of filling the technical gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

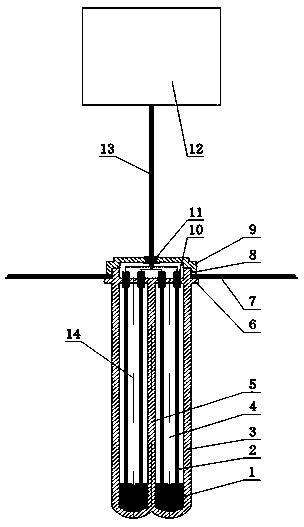

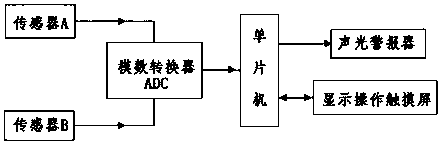

[0033] An online metering device for automatically judging inaccuracy, including sensor A4, sensor B14, analog-to-digital converter, single-chip microcomputer, display operation touch screen and sound and light alarm;

[0034] Sensor A4 and sensor B14 are used to detect the same physical quantity. Sensor A4 and sensor B14 of this embodiment are selected as temperature sensors. According to actual needs, those skilled in the art can also set sensor A4 and sensor B14 as pressure sensors and displacement sensors. , speed sensor, humidity sensor and other types of sensors;

[0035] The sensor A4 and the sensor B14 are integrated in the integrated device. The integrated device includes an insulating protective tube 3, a fixed cover 9 and a mounting plate 7. The insulating protective tube 3 is a cavity container, and the cavity of the insulating protective tube 3 is provided with a vertical partition 5 , the vertical partition 5 divides the inner cavity of the insulating protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com