Graphene and preparation method thereof

A technology of graphene and nitrogen-doped graphene, which is applied in the field of nitrogen-doped graphene and its preparation, can solve the problems of large discharge current, high risk, high hydrogen pressure, etc., and achieve low production cost, simple equipment, and improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

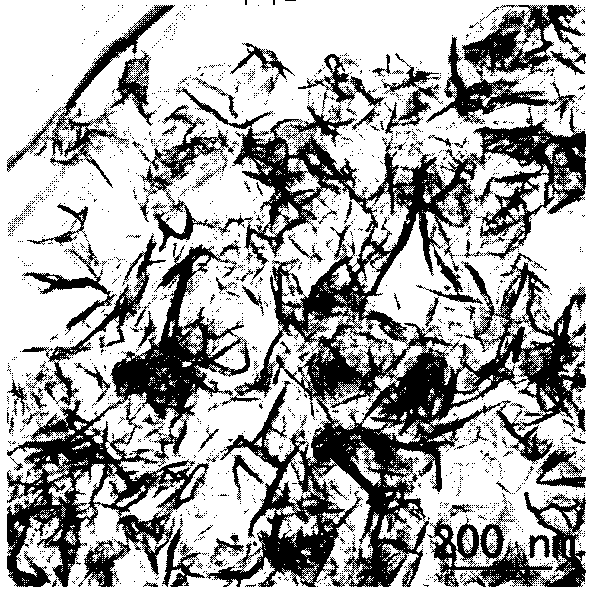

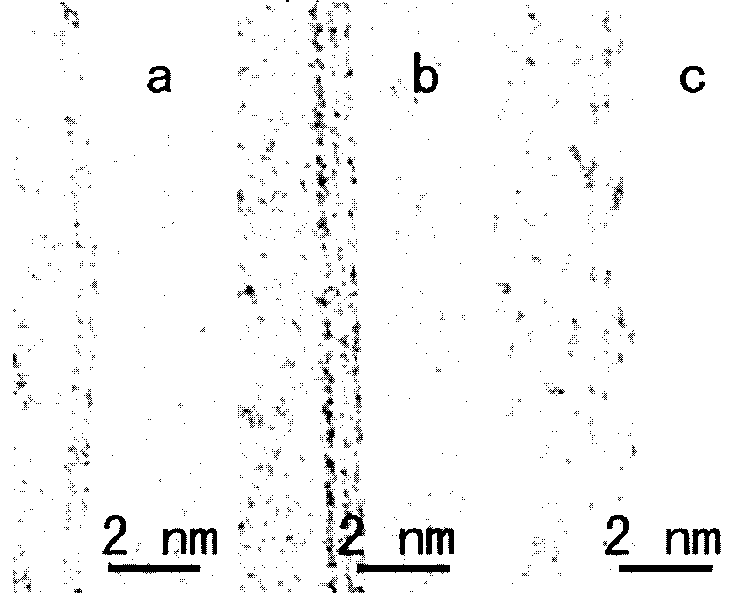

[0030] Graphene is prepared in an electric arc furnace, and the furnace wall of the electric arc furnace is cooled with circulating water. Spectrally pure graphite rods are used as the cathode and anode of the electric arc furnace respectively, and the diameter of the graphite rods at both poles is 8 mm. Under the conditions of a mixture of helium and ammonia (volume ratio 1:1) at a pressure of 760 Torr and a current of 120 A, DC arc discharge is carried out. After the anode was consumed, the product was collected and burned in air at 450°C for 1 hour to obtain nitrogen atom-doped graphene. The scanning electron micrograph of the graphene, as figure 1 shown. From figure 1 The protruding edges of graphene can be seen in the figure, indicating that flake graphene is produced; figure 2 It is a transmission electron micrograph of the graphene, and the size of the graphene sheet is between 100-200 nanometers; image 3 It is a high-resolution transmission electron microscope p...

Embodiment 2

[0032] Graphene is prepared in an electric arc furnace, and the furnace wall of the electric arc furnace is cooled with circulating water. Spectrally pure graphite rods are used as the cathode and anode of the electric arc furnace respectively, and the diameter of the graphite rods at both poles is 8 mm. Under the conditions of a mixture of helium and ammonia (volume ratio 1:2) at a pressure of 760 Torr and a current of 120 A, direct current arc discharge is carried out. After the anode was consumed, the product was collected and burned in air at 450°C for 1 hour to obtain nitrogen atom-doped graphene.

Embodiment 3

[0034] Graphene is prepared in an electric arc furnace, and the furnace wall of the electric arc furnace is cooled with circulating water. Spectrally pure graphite rods are used as the cathode and anode of the electric arc furnace respectively, and the diameter of the graphite rods at both poles is 8 mm. Under the conditions of a mixture of helium and ammonia (volume ratio 1:3) at a pressure of 380 Torr and a current of 80 A, DC arc discharge is performed. After the anode was consumed, the product was collected and burned in air at 500°C for 1 hour to obtain nitrogen atom-doped graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com