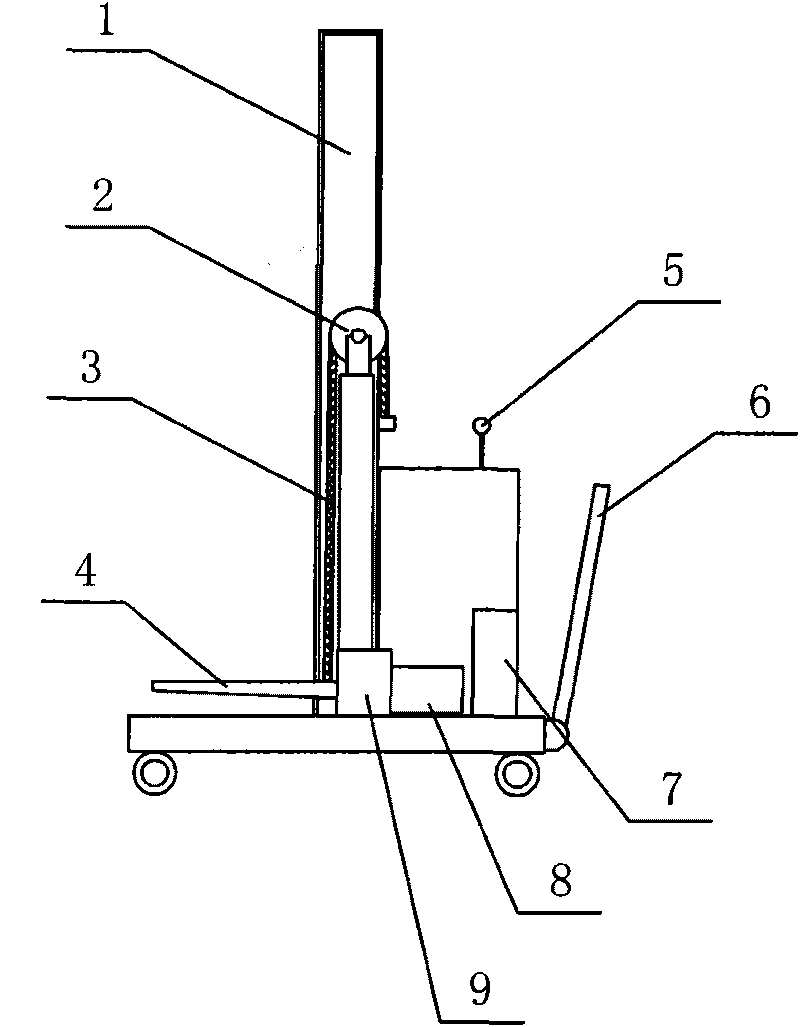

Fork lifting device and electric fork truck

A fork and electric technology, which is applied in the direction of lifting devices, etc., can solve the problems of low service life, low transmission efficiency, and high operating noise, and achieve the effects of long service life, convenient system installation, and low operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

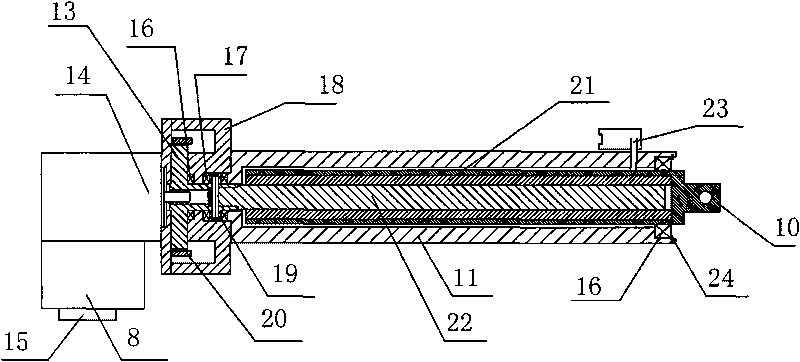

[0032] The fork lifting device of the present invention includes a transmission motor and a motor control system, a reducer linked with the drive motor, an electric ball screw cylinder linked with the reducer, a transmission sprocket and a transmission chain; the electric ball screw cylinder includes a rotating assembly, Translating assembly, brake system; rotating assembly includes bearing chamber, lead screw, and two pressure bearings arranged in the bearing chamber; one end of the lead screw is provided with an external thread, and the other end is coaxially connected with the output shaft of the reducer, and the middle circumference A limiting pillow block perpendicular to the axial direction of the screw is arranged on the side; the limiting pillow block is arranged in the bearing chamber, and two pressure bearings are respectively arranged on both axial sides of the limiting pillow block; The executive rod in the limit seat, the nut that can be combined with the lead scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com