Frozen sour milk and manufacturing method thereof

A technology of frozen yogurt and its production method, which is applied in the fields of frozen desserts, food science, and applications. It can solve the problems of large ice edges and ice residues, the inability to restore the delicate taste of ice cream, and affect product quality. It achieves smooth taste, low hardness, The effect of rich and sweet flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

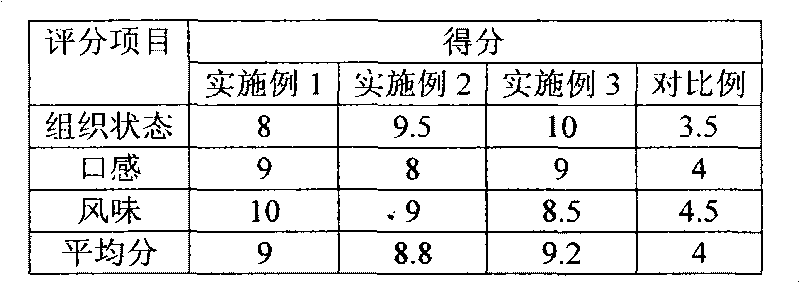

Examples

Embodiment 1

[0037] The raw material formula of the frozen yogurt of the present embodiment: white granulated sugar 9%, corn syrup 3% (sweetness is 35% of sucrose), whole milk powder 3%, whey powder 2%, aspartame 0.012%, anhydrous Butter 4%, coconut oil 4%, stabilizer 0.5% (0.3% starch + 0.15% gelatin + 0.05% pectin), lactic acid bacteria starter (purchased from Danisco MY-75) 0.009%, the balance of milk. The performance indicators of each raw material meet the requirements of relevant quality standards.

[0038] The technological process of the frozen yogurt of the present embodiment is roughly as follows:

[0039] Raw milk inspection, standardization→ingredients→degassing→homogenization→sterilization→cooling→inoculation→stirring→insulation fermentation→demulsification→cooling→filling→freezing. The specific process can be carried out as follows:

[0040] 1. Raw milk inspection: It mainly tests several indicators of raw milk, such as sensory perception, acidity, fat, protein, whole milk ...

Embodiment 2

[0052] The raw material formula of the frozen yogurt of the present embodiment: white granulated sugar 8.5%, corn syrup 3.5%, whole milk powder 3%, whey powder 2%, aspartame 0.02%, anhydrous butter 4.5%, coconut oil 4%, Stabilizer 0.45% (0.2% starch + 0.15% gelatin + 0.1% pectin), lactic acid bacteria starter (purchased from Danisco MY-75) 0.009%, the balance of milk. The performance indicators of each raw material meet the requirements of relevant quality standards.

[0053] The technological process of the frozen yogurt of the present embodiment is roughly as follows:

[0054] Raw milk inspection, standardization→ingredients→degassing→homogenization→sterilization→cooling→inoculation→stirring→insulation fermentation→demulsification→cooling→filling→freezing. The specific process can be carried out as follows:

[0055] 1. Raw milk inspection: It mainly tests several indicators of raw milk, such as sensory perception, acidity, fat, protein, whole milk solids, adulteration, ant...

Embodiment 3

[0067] The raw material formula of the frozen yogurt of this embodiment: white granulated sugar 9.5%, corn syrup 2.5%, whole milk powder 4%, whey powder 1.5%, acesulfame potassium 0.015%, anhydrous butter 3.5%, coconut oil 4.5%, stable 0.5% (0.3% starch + 0.15% gelatin + 0.05% pectin), 0.009% lactic acid bacteria starter (purchased from Danisco MY-75), and the rest of milk. The performance indicators of each raw material meet the requirements of relevant quality standards.

[0068] The making method of the frozen yogurt of the present embodiment is roughly as follows:

[0069]1. Raw milk inspection: It mainly tests several indicators of raw milk, such as sensory perception, acidity, fat, protein, whole milk solids, adulteration, antibiotics, etc., and standardizes the qualified milk according to the indicators;

[0070] 2. Ingredients: Heat the standardized milk to about 80°C, add the above-mentioned stabilizer, whole milk powder, whey powder, aspartame, anhydrous butter, coc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com