Electrochemical super capacitor and manufacturing method thereof

A technology for supercapacitors and manufacturing methods, applied in the field of capacitors, can solve the problems of poor consistency of electrochemical supercapacitor monomers, increased process complexity, and complicated lamination process operations, so as to ensure ion permeability, improve safety and Stability and accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

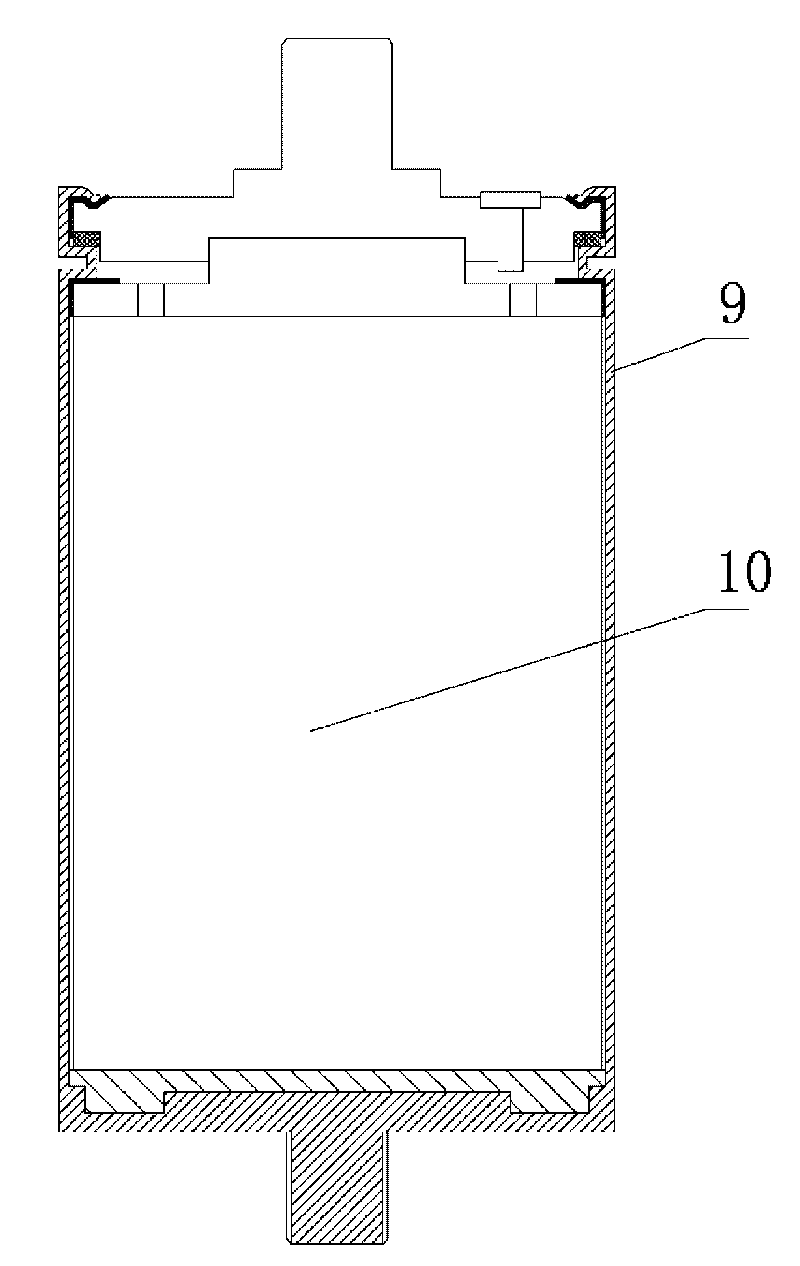

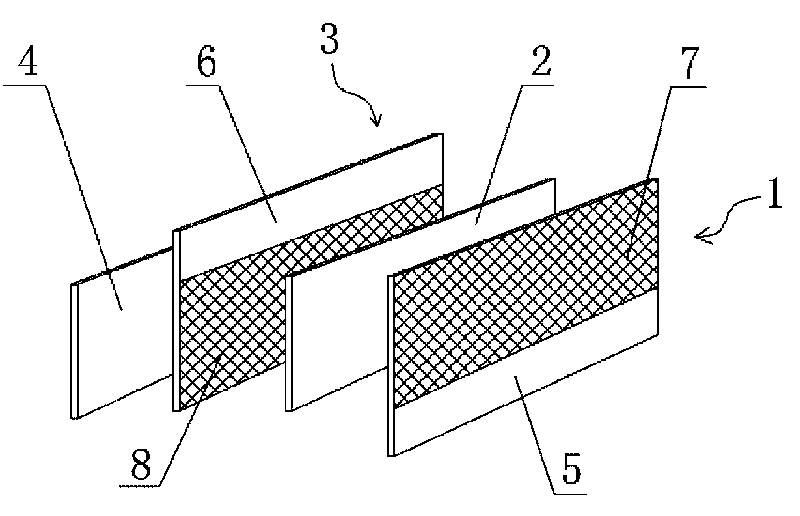

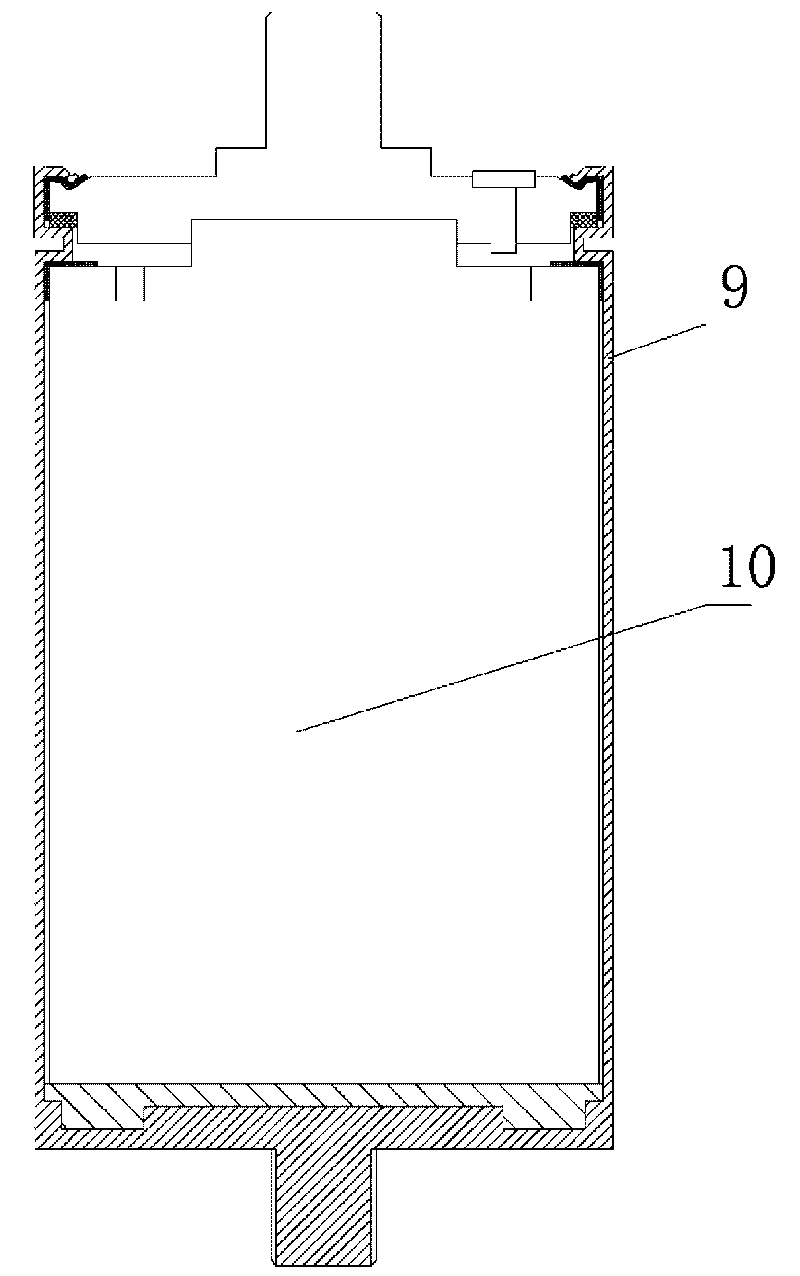

[0019] The structure of the electrochemical supercapacitor provided by the invention is as figure 1 As shown, it includes an electrode winding core 10 and a casing 9, the electrode winding core 10 is inserted into the casing 9, and the casing 9 is an electrode lead-out end of the electrochemical supercapacitor. The schematic diagram of the structure when the electrode winding core 10 is unfolded is as follows: figure 2 As shown, the first pole piece 1, the outer diaphragm 2, the second pole piece 3, and the inner diaphragm 4 are stacked sequentially from outside to inside to form a strip-shaped coil to be wound. After being wound into a roll, it is the supercapacitor Electrode winding core 10. The outer diaphragm 2 comprises a polypropylene non-woven fabric layer and a polyethylene grafted film layer adhered to its surface, the inner diaphragm 4 is a polypropylene porous film, and a lateral side of the first pole piece 1 is integrally provided with a longitudinally extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com