Absorption refrigerating machine

An absorption refrigerator, cold temperature technology, applied in the direction of adsorption machines, refrigerators, refrigeration components, etc., to prevent excessive temperature drop, reduce combustion, and increase the average COP effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

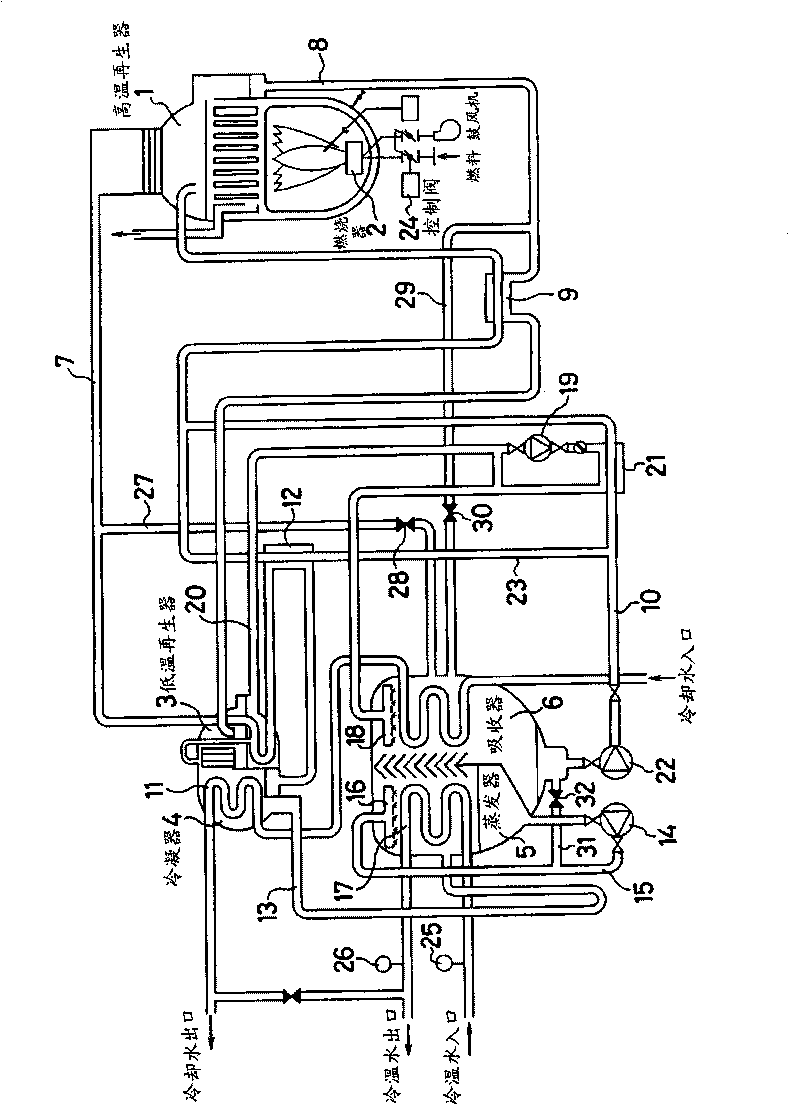

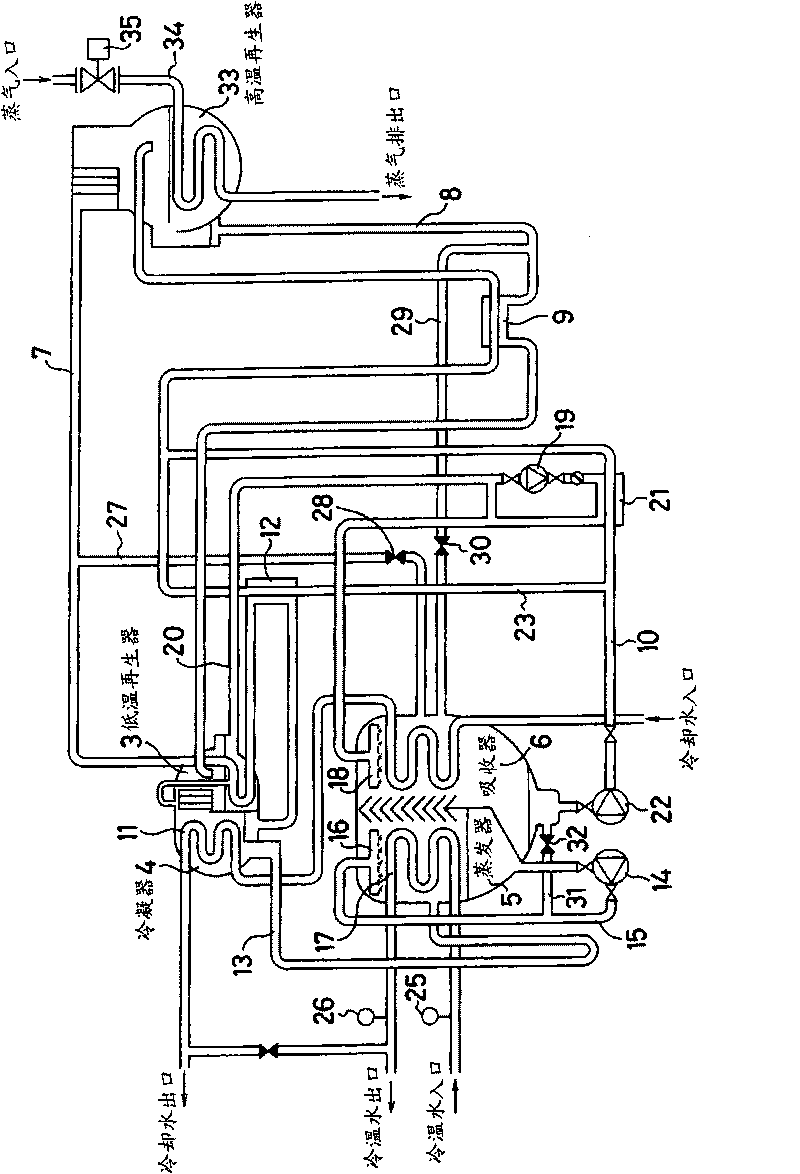

[0060] Hereinafter, embodiments of the present invention will be described based on the drawings. figure 1 It is a structural diagram showing the first embodiment of the absorption refrigerator of the present invention.

[0061] exist figure 1 Among them, reference numeral 1 is a high-temperature regenerator, and has a burner 2 as a heating source, and heats the diluted absorption liquid returned from the absorber 6 to vaporize and separate refrigerant vapor. The high-temperature refrigerant vapor evaporated and separated in the high-temperature regenerator 1 passes through the interior of the low-temperature regenerator 3 via the refrigerant pipe 7 , and is supplied to the bottom of the condenser 4 . In addition, the medium-concentration intermediate absorption liquid obtained by evaporating and separating the refrigerant vapor in the high-temperature regenerator 1 is supplied to the low-temperature regenerator 3 through the intermediate absorption liquid pipe 8 . A high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com