Longitudinal shaft assembly for a motor vehicle

A longitudinal axis, automotive technology, used in controls, couplings, shafts and bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

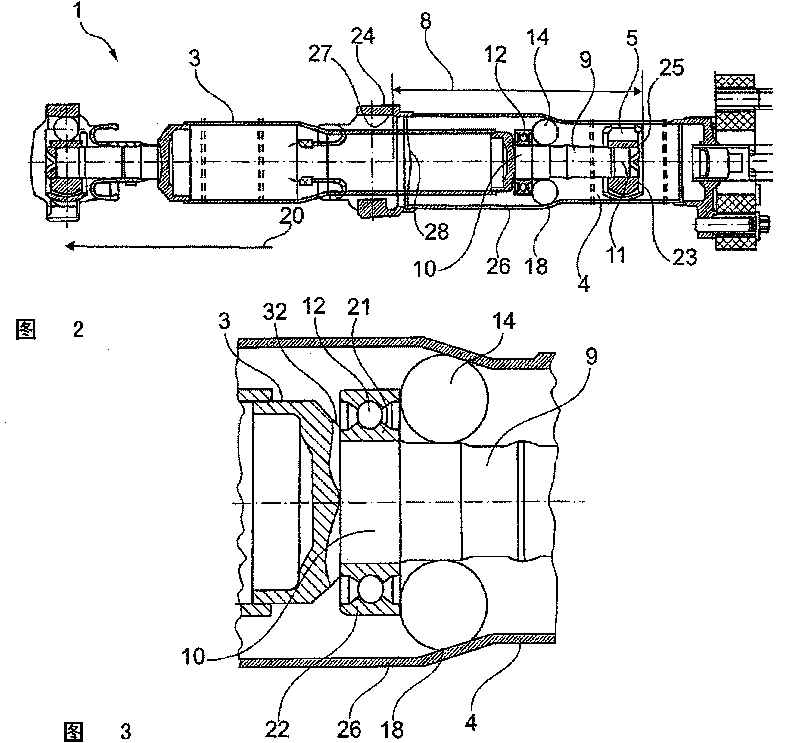

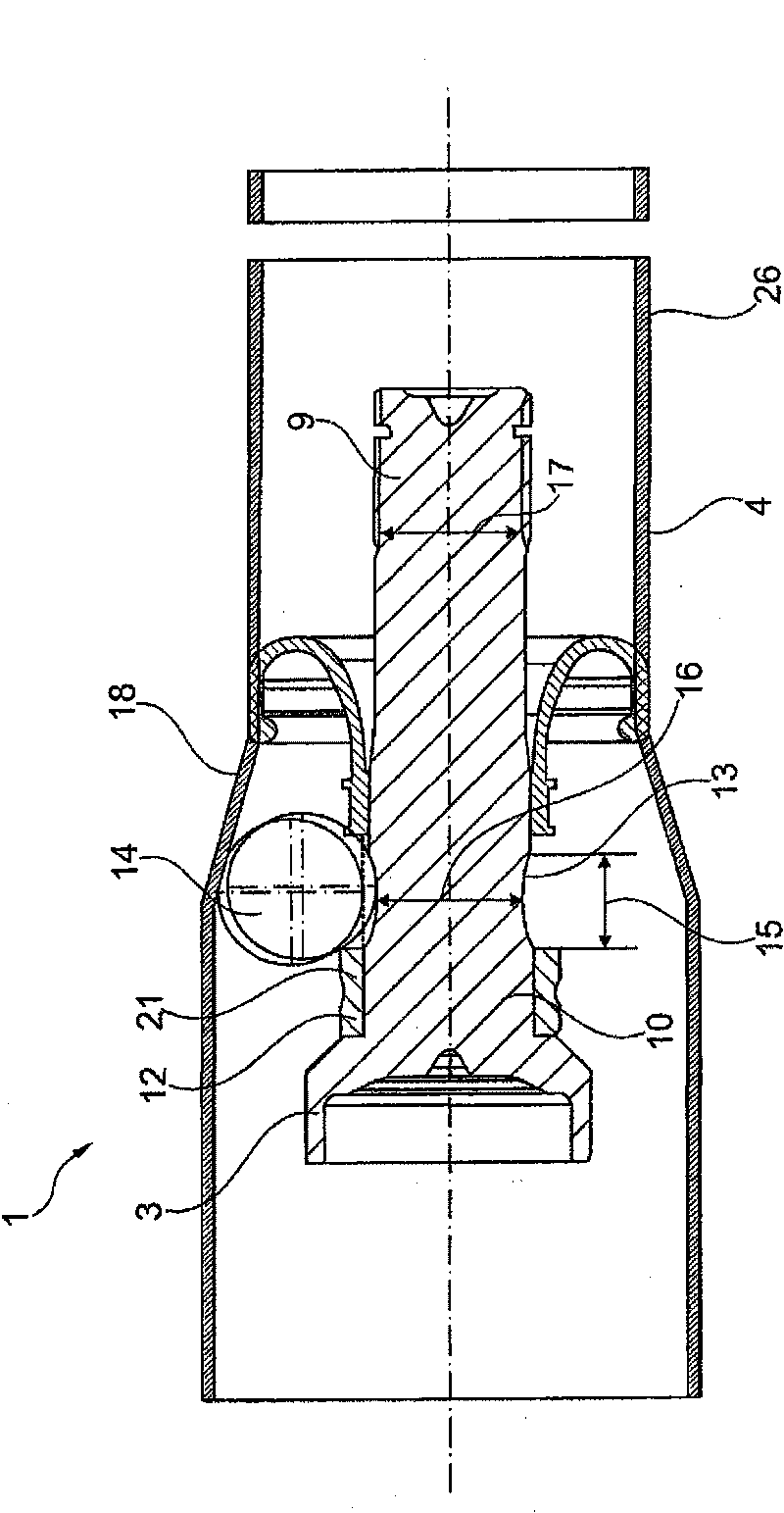

[0025] figure 1 The longitudinal axis device 1 of a motor vehicle 2 is shown, the direction of travel 20 of the motor vehicle 2 is in figure 1 The lower part is shown. The longitudinal axis device 1 consists at least of a first shaft 3 and a second shaft 4, which are connected to each other via a spherical synchronous joint 5, here in the form of an axial joint shown in the middle. Offsetable joints ("moving joints"). The first axis 3 itself consists of several components, which are in figure 1 clearly visible in. In particular, on the first shaft 3 there is an additional spherical synchronous joint arranged on the pin of the first shaft 3, as figure 1 shown on the left. Arranged at the other end of the first shaft 3 is a pin 9 which extends into a ball-shaped synchronous joint of the longitudinal shaft arrangement 1 . This bolt 9 is connected at its first end to the joint inner element 23 of the ball synchronous joint 5 on the one hand via its second end 11 and on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com