Pitch mixed material cracking resistance tester

A technology of asphalt mixture and anti-cracking performance, applied in the direction of instruments, scientific instruments, analytical materials, etc., can solve the problems of lack of mature test standards and test instruments, unstable test and detection environment conditions, complicated composition and operation, etc. Achieve the effect of solving the overall structure and complex operation, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

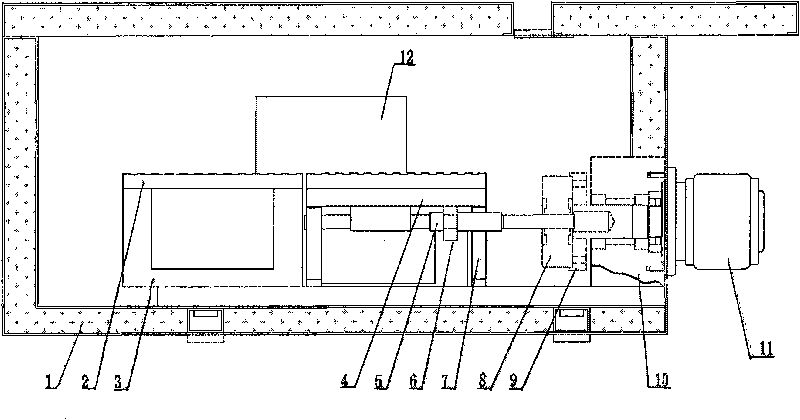

[0014] as attached figure 1 In the shown embodiment, the present invention includes an environmental box 1, a fixed support 3, a bonded platen 2, a sliding plate 4, a sliding plate displacement loading mechanism, a spoke sensor 8, a rotary coupling 9, a servo motor 11, and components of the environmental box 1 The box is equipped with a fixed support 3, and the fixed support 3 is equipped with a bonding platen 2. The bonding platen 2 is dynamically matched with the sliding plate 4, and the bottom of the sliding plate 4 is equipped with a sliding plate displacement loading mechanism. The sliding plate displacement loading mechanism consists of The rotary coupling 9 is connected to the servo motor 11, and a spoke sensor 8 is connected to the coupling disk of the rotary coupling 9. The rotary coupling 9 is equipped with bearings embedded in the side body support 10 of the environmental chamber 1, and the servo motor 11 Installed and connected to the outside of the side body of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com