Method for producing defluorinated ammonium phosphate

A technology for defluorinated ammonium phosphate and production method, which is applied in the directions of phosphates, phosphorus oxyacids, halogenated silicon compounds, etc., can solve the problems of defluorination without wet-process phosphoric acid, reduce fertilizer efficiency, reduce emission pollution, and avoid potassium the effect of the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Raw material 1: Wet-process phosphoric acid, collection location: Shandong Hongri Akang Chemical Co., Ltd.

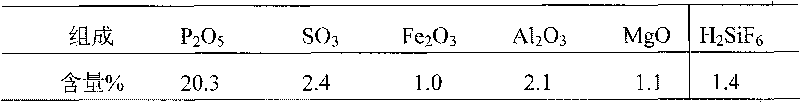

[0019] The chemical composition of wet-process phosphoric acid is shown in the table below

[0020]

[0021] Raw material 2: Potassium sulfate (K 2 SO 4 Content 98%), collection location: Shandong Hongri Akang Chemical Co., Ltd.

Embodiment approach

[0023] The wet-process phosphoric acid is filtered through sedimentation to remove suspended solids, and then massaged by K + : H 2 SiF 6 =2 Add solid potassium sulfate and carry out defluorination reaction at 80℃ for 45min. After the reaction, the material liquid is settled and filtered to remove the solid precipitate. The solid precipitate is washed and dried to become the by-product potassium fluorosilicate; the filtrate is defluorinated phosphoric acid . Neutralize the defluorinated phosphoric acid with ammonia gas, and control the pH value around 6.5.

[0024] The neutralized slurry is concentrated, sprayed and granulated, dried, sieved, and packaged to become the final product of ammonium phosphate.

[0025] Implementation results:

[0026] 1. Defluorinated ammonium phosphate

[0027] The N content in the prepared defluorinated ammonium phosphate is 10.5%, P 2 O 5 The content is 47.3%, the total nutrient NPK≥45%, which meets the requirements of high-concentration compound ferti...

Embodiment 2

[0031] Raw material 1: Wet-process phosphoric acid, collection location: Shandong Hongri Akang Chemical Co., Ltd.

[0032] The chemical composition of wet-process phosphoric acid is shown in the table below

[0033]

[0034] Raw material 2: Potassium chloride (KCl content 98%), collection location: Shandong Hongri Akang Chemical Co., Ltd.

[0035] method of execution:

[0036] The wet-process phosphoric acid is filtered through sedimentation to remove suspended solids, and then massaged by K + : H 2 SiF 6 =1.5 Add solid potassium chloride and carry out defluorination reaction at 60°C for 90 minutes. The reacted material is settled and filtered to remove the solid precipitate. The solid precipitate is washed and dried to become the by-product potassium fluorosilicate; the filtrate is defluorination Phosphoric acid. The defluorinated phosphoric acid and ammonia gas are ammoniated in an ammoniating granulator (control the pH value to be around 6.5), granulating, drying, screening, packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com