Overwater replacing method of structure of stay tube

A technology for pipe structures and components, which is applied in the field of water dismantling and replacement of support pipe structures, can solve the problems of long occupancy docking period and inability to guarantee the replacement accuracy of support pipes, so as to reduce costs, reduce costs, and save labor and flexibility in replacement construction operations. The effect of structural deformation and even instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

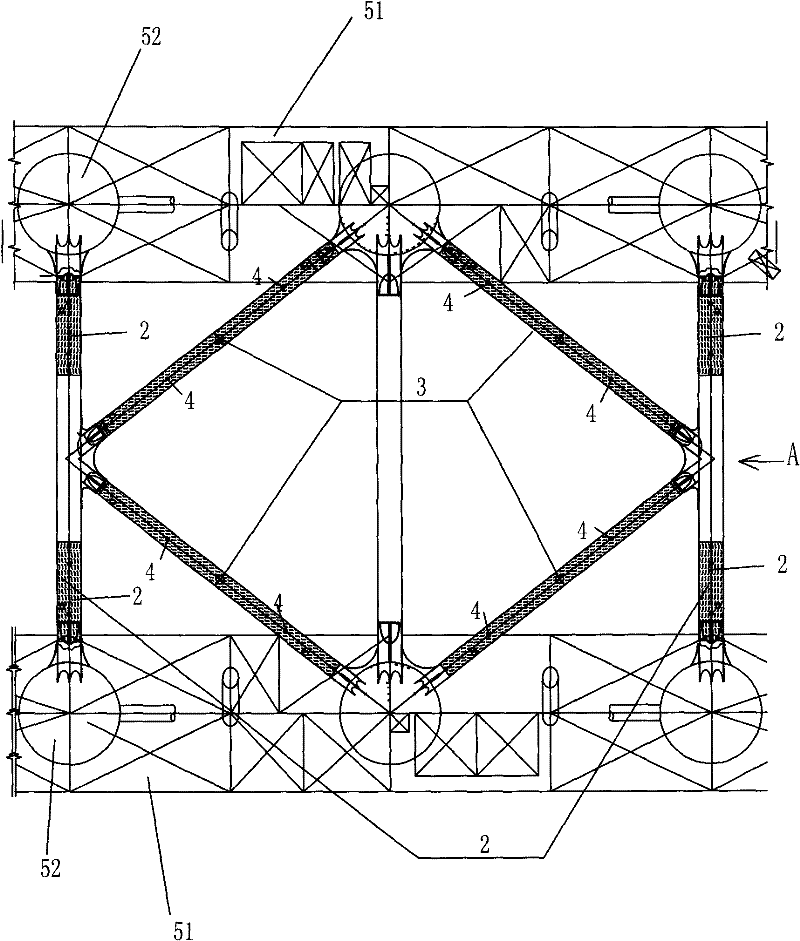

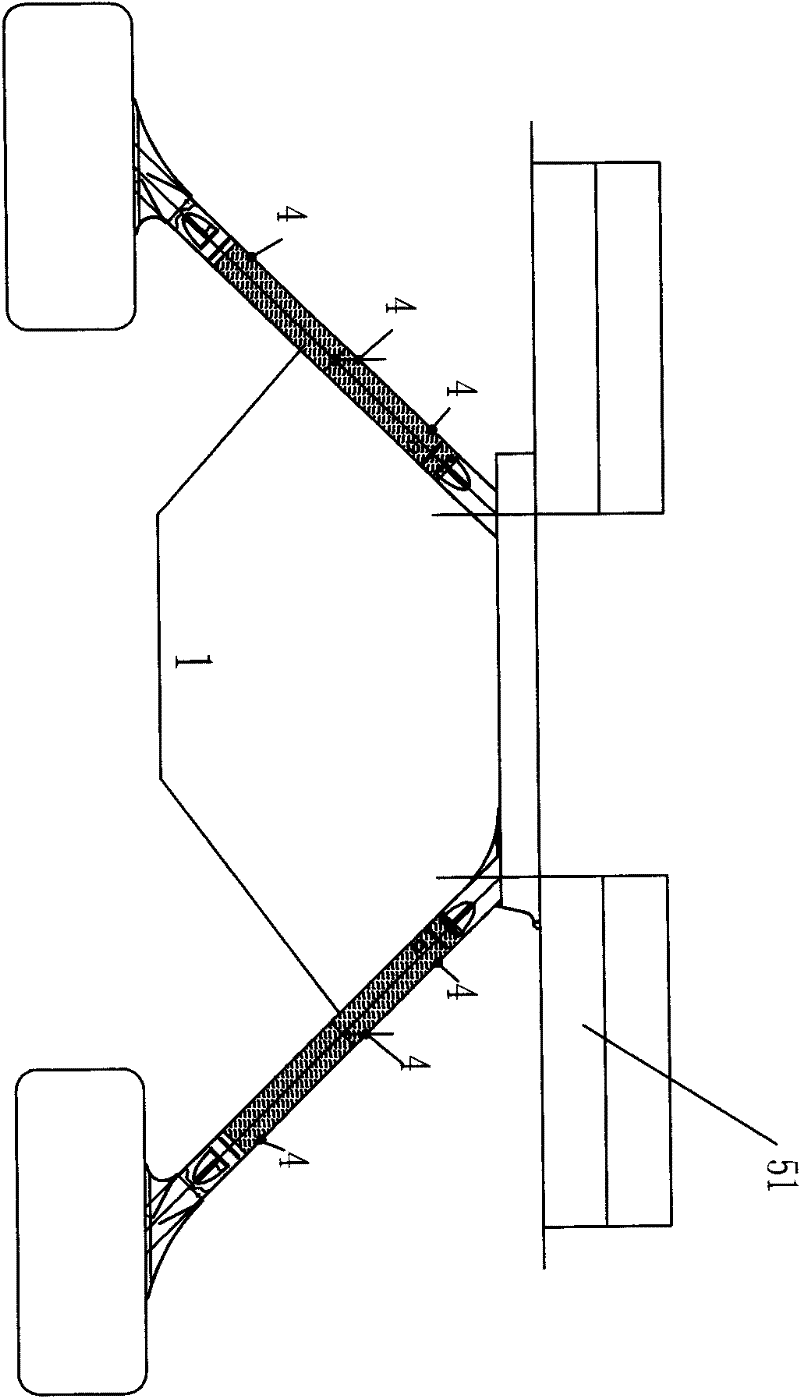

[0022] The method of the present invention mainly includes the general process regulations for removing and replacing the support pipe on the water surface, and its specific content is as follows:

[0023] 1. First remove and replace the support tubes that have less influence on the platform deformation, and finally remove and replace the support tubes that have a greater influence on the platform deformation;

[0024] 2. Before the original pipe is cut, in order to prevent the structural deformation of the support pipe, the temporary reinforcement support pipe must be installed in advance, and the new support pipe must be replaced and welded before the temporary reinforcement support pipe can be removed;

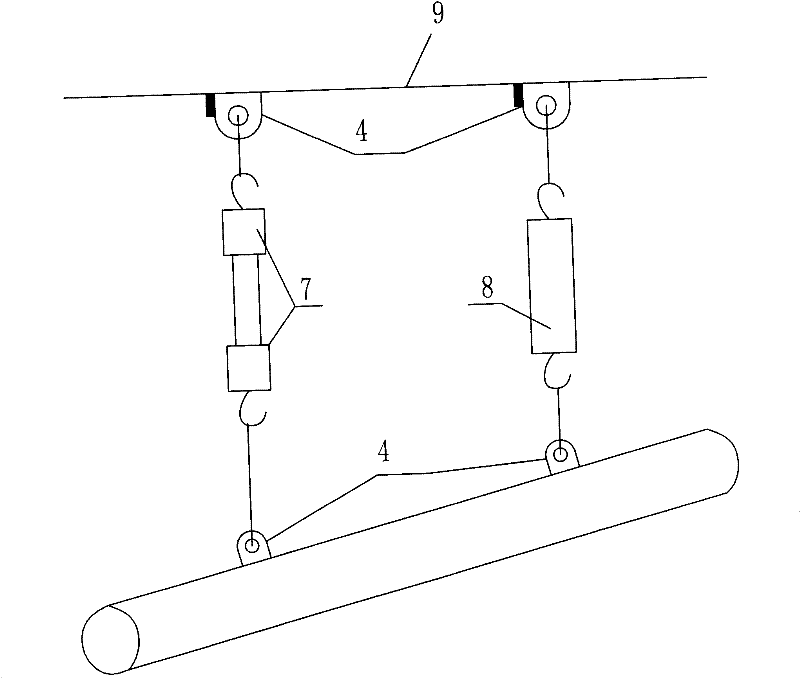

[0025] 3. The removal and installation of the switching support tubes on the water surface is carried out by hanging the pulley block as the main method and the chain hoist as the auxiliary method. The removal and the transportation of the new support tubes need to be carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com