Automobile disk-type braking method and device based on motor drive

A disc brake, motor-driven technology, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve the problems of high price and complex structure, and achieve the effect of low cost, simple and compact structure, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

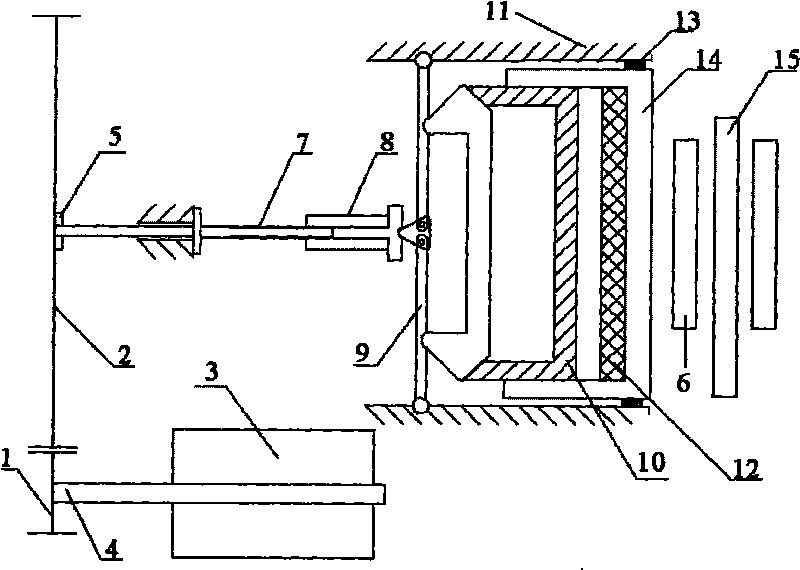

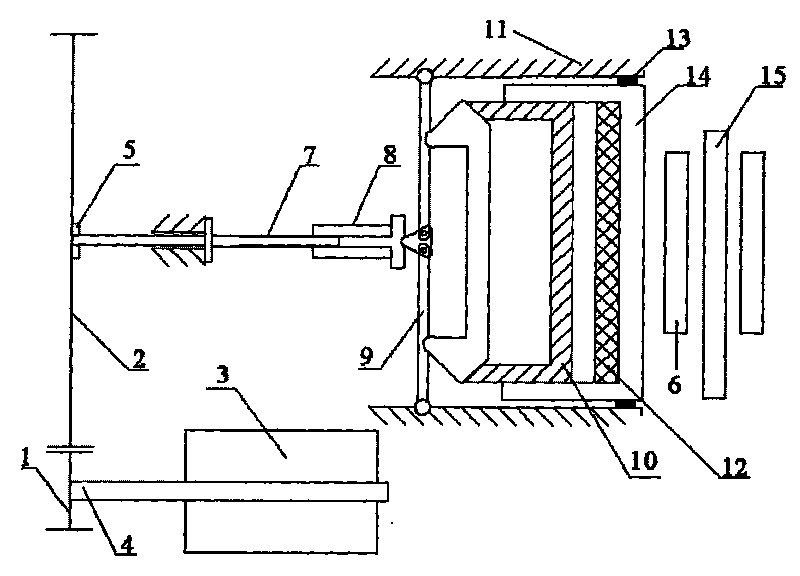

[0019] As shown in the figure, the brake includes a brake piston 14, a brake block 6, and a brake disc 15. The brake piston 14 can push the brake block 6 to press the brake disc 15, which is the prior art.

[0020] The power output shaft 4 of the 12V DC brushless motor 3 is equipped with a driving gear 1, and the driven gear 2 meshes with the driving gear. The transmission ratio of the driving gear 1 and the driven gear 2 is 1:40; the driven gear 2 passes through the spline 5 Connected with the screw rod 7, there is a nut 8 matched with the screw rod, the nut 8 is connected to the end of the booster lever 9, a transmission sleeve 10 is arranged between the booster lever 9 and the brake piston 14, and the booster lever 9 passes through The transmission sleeve 10 drives the brake piston 14 to move. A pressure sensor 12 is installed inside the brake piston, which is used to measure the output braking torque and realize precise control of braking. A return rubber ring 13 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com