Method for treating tobacco stem

A technology for cut stems and tobacco leaves, applied in the field of tobacco, can solve problems such as complex processes, and achieve the effects of reducing lignin gas, reducing lignocellulose content, and improving filling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

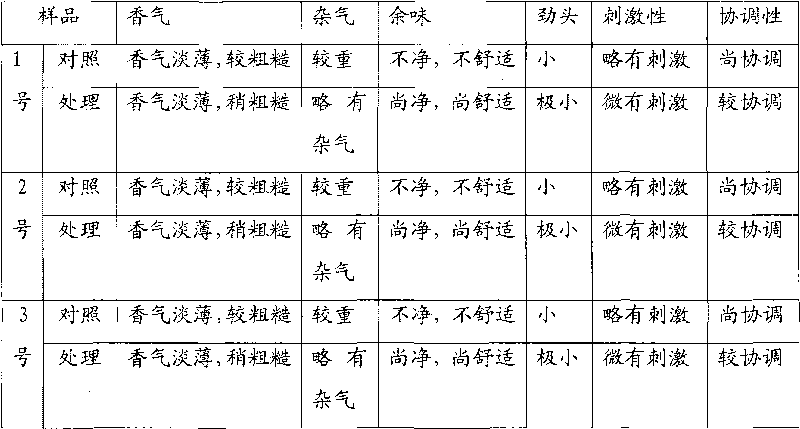

[0027] Embodiment 1: the method of the present invention handles shredded tobacco leaf stems

[0028] Several parts (10g / part) cut stems were mixed with 4% (mass percent) ammonia solution and 3.6% (volume percent) H 2 o 2 Soak in the mixed solution for 3 hours at 90°C, filter, rinse the filter residue twice with tap water, and dry at 80°C for 6 hours. Its water content is 13% after testing.

Embodiment 2

[0029] Embodiment 2: the method of the present invention handles shredded tobacco leaf stems

[0030] Several parts (10g / part) cut stems were mixed with 0.5% (mass percentage) ammonia solution and 0.5% (volume percentage) H 2 o 2 Soak in the mixed solution for 0.5h at 50°C, filter, rinse the filter residue twice with tap water, and dry at 80°C for 4h, the water content is 11% after testing.

Embodiment 3

[0031] Embodiment 3: the method of the present invention handles shredded tobacco leaf stems

[0032] Several parts (10g / part) cut stems were mixed with 4% (mass percentage) ammonia solution and 0.5% (volume percentage) H 2 o 2 Soak in the mixed solution for 1 hour at 60°C, filter, rinse the filter residue twice with tap water, and dry at 80°C for 4 hours. The water content is 11.5% after testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com