Process for treating cut stems of tobacco leaves

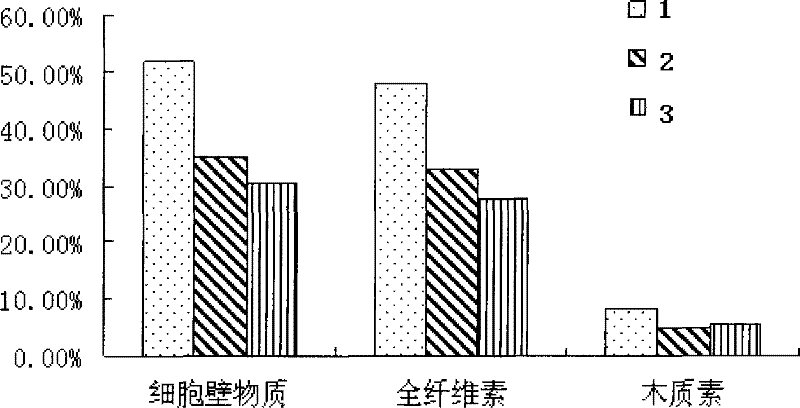

A technology of shredded stems and tobacco leaves, applied in the field of tobacco, can solve problems such as complicated process and negative impact on aroma, and achieve the effects of improving sensory quality, reducing woodiness and irritation, and improving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

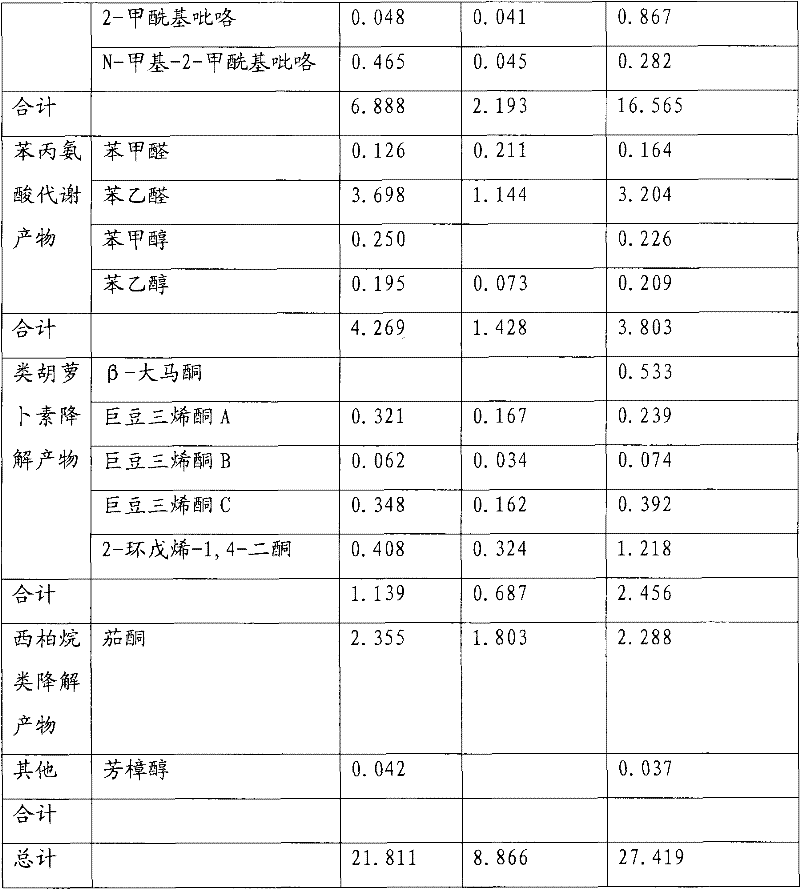

[0032] Embodiment 1: Existing method handles shredded tobacco leaf stalks (abbreviation alkali-oxygen treatment)

[0033] Take cut stems of a certain quality, spray and add 10% ammonia water in a mass ratio of 5: 1 (cut stems: ammonia water), and add 10% ammonia water in a mass ratio of 7: 1 (cut stems: H 2 o 2 ) proportional spraying and adding 10% H 2 o 2 , placed in a constant temperature oven at 60°C for 2 hours, sprayed with 10% citric acid at a ratio of 3:1 (stem: citric acid), and dried at 40°C.

Embodiment 2

[0034] Embodiment 2: the method of the present invention handles shredded tobacco leaf stems

[0035] Take cut stems of a certain quality, spray and add 1.5% ammonia water in a mass ratio of 15: 1 (cut stems: ammonia water), and add 1.5% ammonia water in a mass ratio of 7: 1 (cut stems: H 2 o 2 ) proportional spraying with 3% H 2 o 2 , placed in a constant temperature oven at 40°C for 3 hours, sprayed with 5% citric acid at a ratio of 5:1 (stem: citric acid), and dried at 40°C.

[0036] Accurately weigh 100 g of the above-mentioned treated cut stems, spray and add compound enzyme liquid (containing 0.5% amylase, 0.5% protease, and 0.5% cellulase) in a mass ratio of 10:1 (stem cut: compound enzyme liquid) , placed in a constant temperature oven at 30°C for 4 hours, then raised the temperature to 85°C for 4 hours to inactivate the enzyme to terminate the reaction.

Embodiment 3

[0037] Embodiment 3: the method of the present invention handles shredded tobacco leaf stems

[0038] Take cut stems of a certain quality, spray and add 15% ammonia water in a mass ratio of 5: 1 (cut stems: ammonia water), and add 15% ammonia water in a mass ratio of 2: 1 (cut stems: H 2 o 2 ) proportional spraying and adding 15% H 2 o 2 , placed in a constant temperature oven at 80°C for 2 hours, sprayed with 15% citric acid at a ratio of 15:1 (stem: citric acid), and dried at 40°C.

[0039] Accurately weigh 100 g of the above-mentioned treated cut stems, spray and add compound enzyme solution (containing 3% amylase, 3% glucoamylase, and 3% hemicellulase) in a mass ratio of 5:1, and place in a constant temperature oven at 60°C. Leave the reaction for 1 hour, raise the temperature to 95°C and leave it for 1 hour to inactivate the enzyme to terminate the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com