Wind speed balance method and unit control device of wire feeding pipe of cigarette making machine

A technology of unit control and wire feeding tube, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problem that the stability of the wind speed control of the wire feeding tube is not true, and cannot meet the requirements of fine control, independence and stability Insufficient and other problems, to achieve the effect of compact structure, convenient installation and debugging, and strong independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

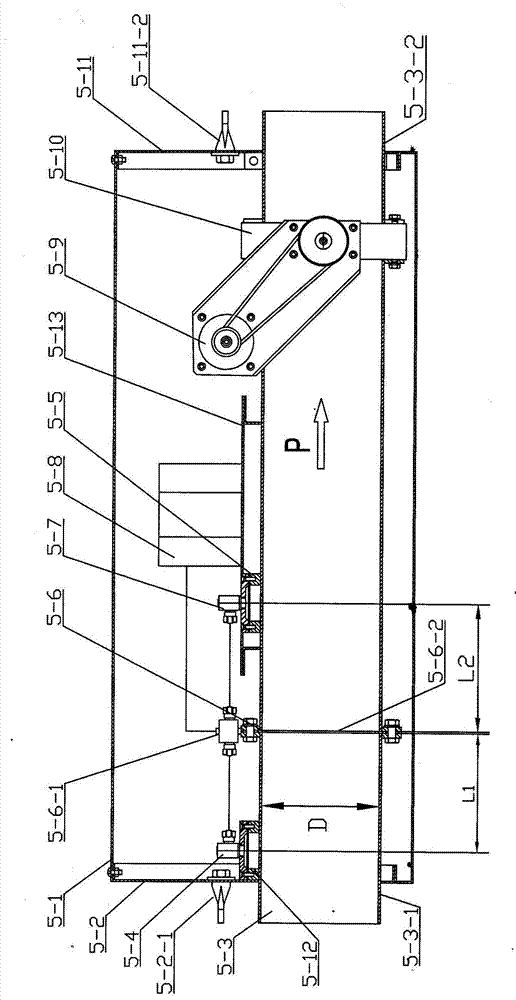

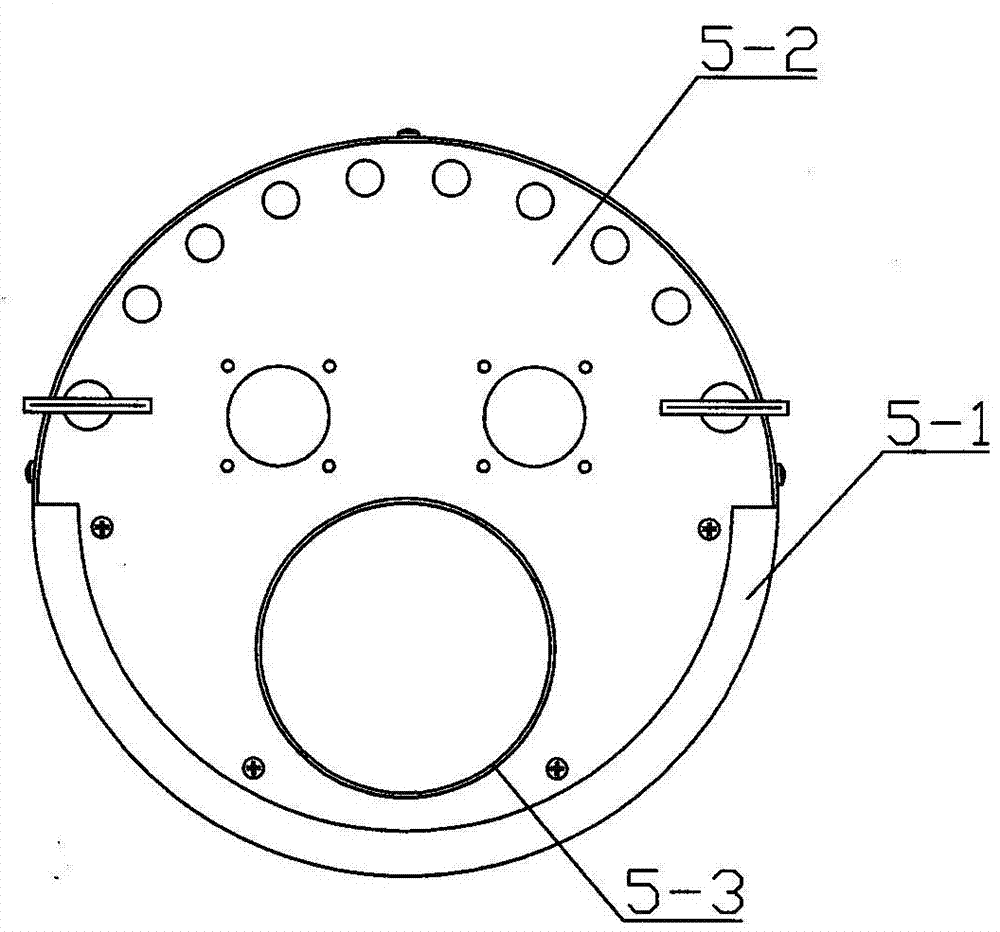

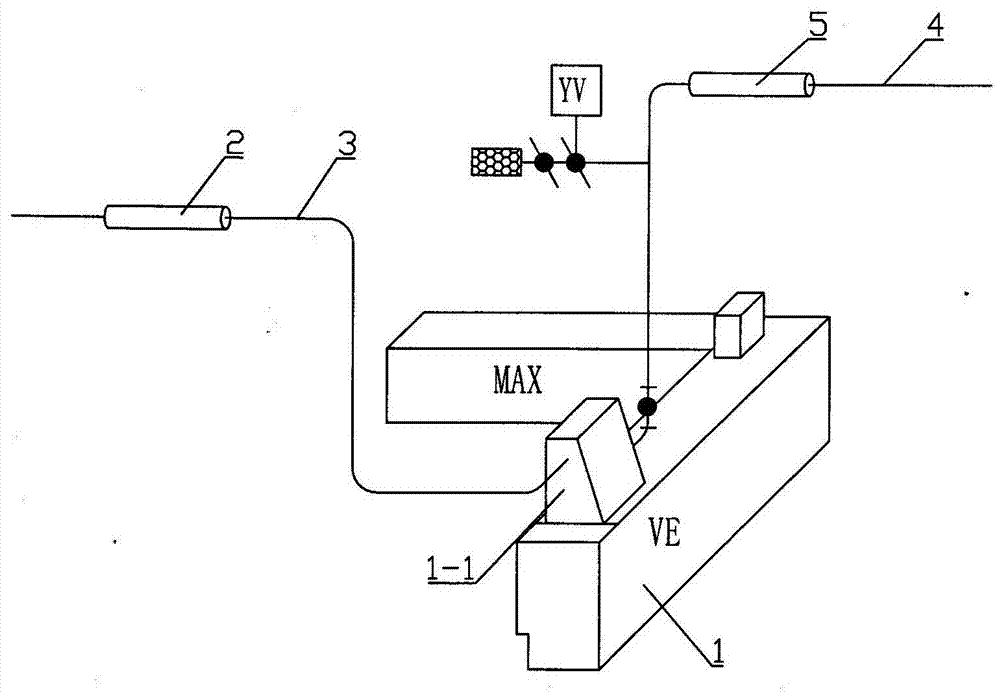

[0032] A method for balancing the wind speed of a wire feeding pipe of a cigarette machine, in which a unit control device 5 is installed on the return air pipe 4 of a cigarette machine 1 to form a closed loop with the wire pipe anemometer 2 originally installed on the wire feeding pipe 3 of the cigarette machine The wire feeding pipe 3 is connected to the air inlet of the silk suction hopper 1-1 on the cigarette machine 1, and the air return pipe 4 is connected to the air outlet of the silk suction hopper 1-1, and a single cigarette machine 1 is used as a control unit , directly collect the wind speed of the wire feeding pipe 3 and the wind speed of the return air pipe 4, use the wind speed of the wire feeding pipe 3 as the feedback signal of the PID closed-loop control, and use the unit control device 5 to directly control the wind speed of the wire feeding pipe 4, so as to realize the air delivery of the cigarette machine Fine control of wire wind balance.

[0033] The unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com