Paint immersing method of stator of outdoor open-type motor

A motor stator and open-type technology, which is applied to the field of outdoor open-type motor stator dipping, can solve the problems of loss and loss, and achieve the effect of improving the dipping effect and increasing the amount of remains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

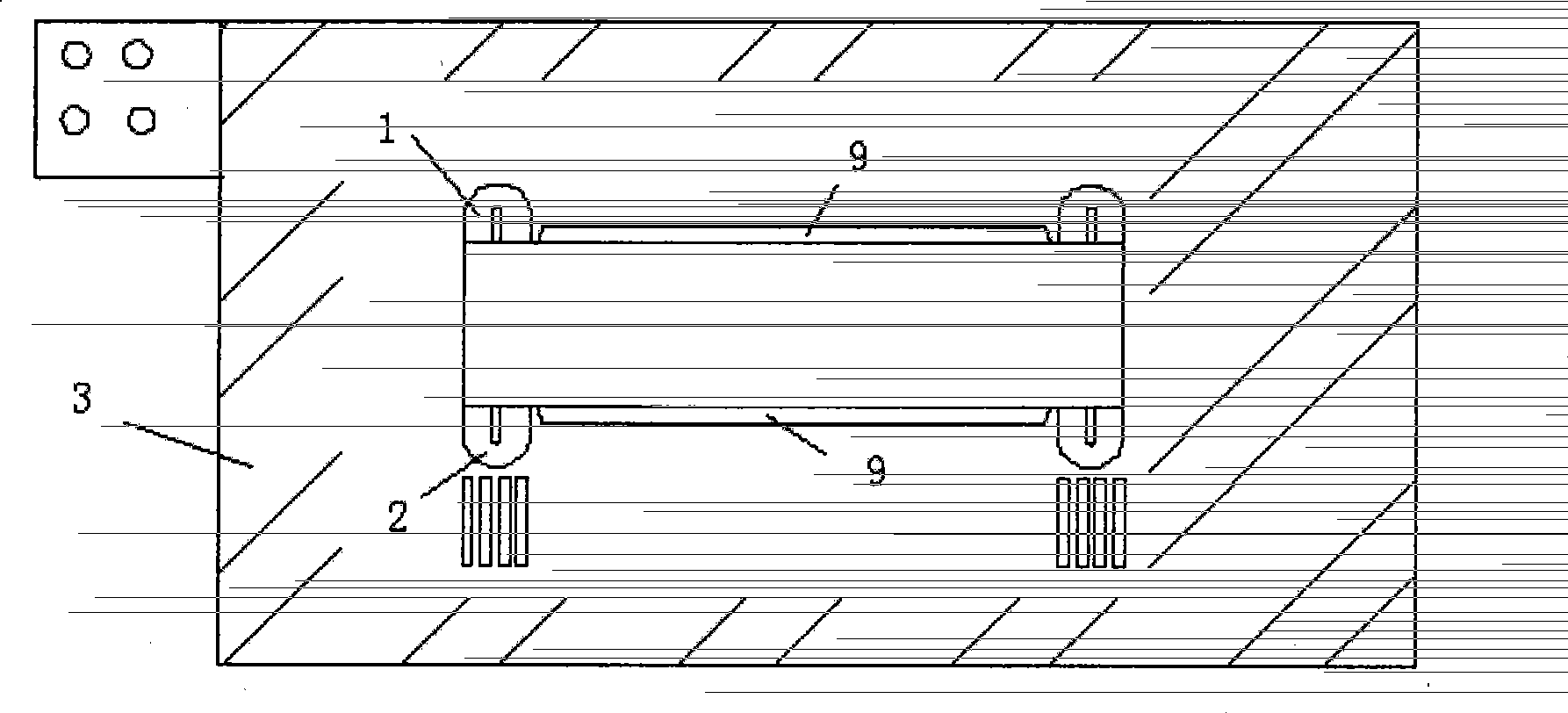

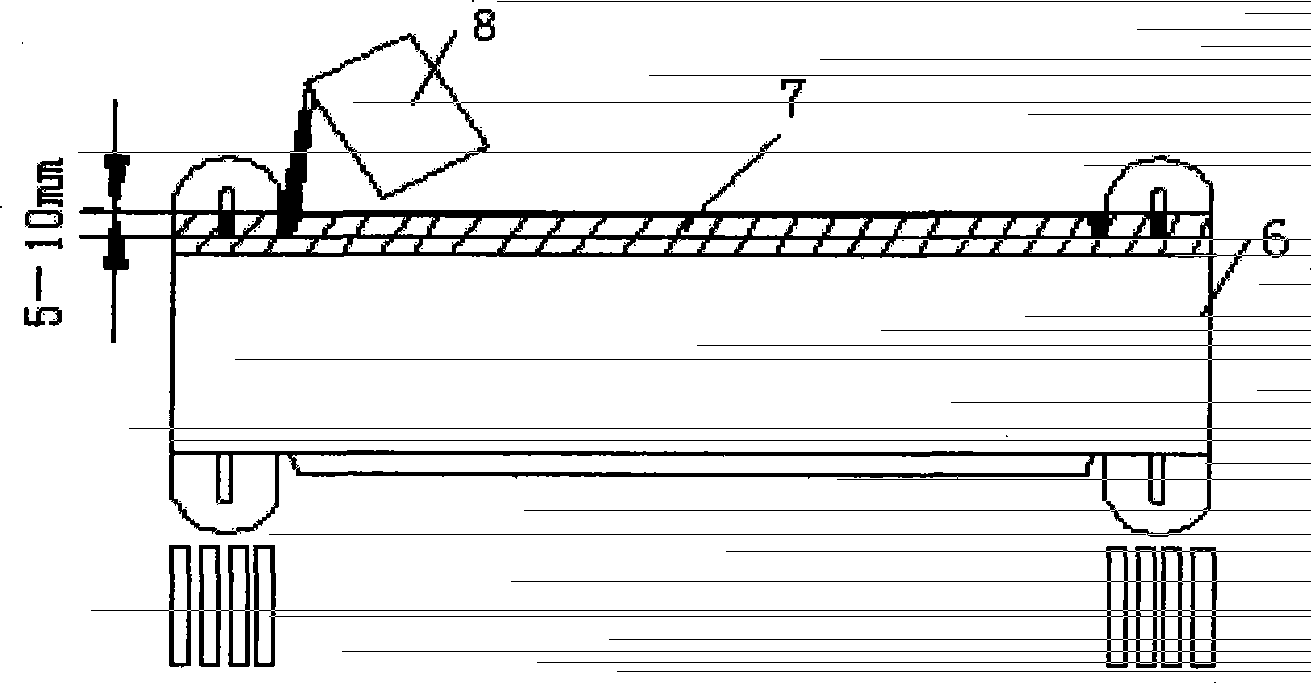

[0022] refer to Figure 1 to Figure 7 One embodiment of the present invention is described:

[0023] (1) Keep the non-outlet end end 1 of the vertical motor stator upward;

[0024] (2) Hang the stator into the drying room 3, keep the temperature at 155°C, and pre-dry for 2.5 to 3 hours;

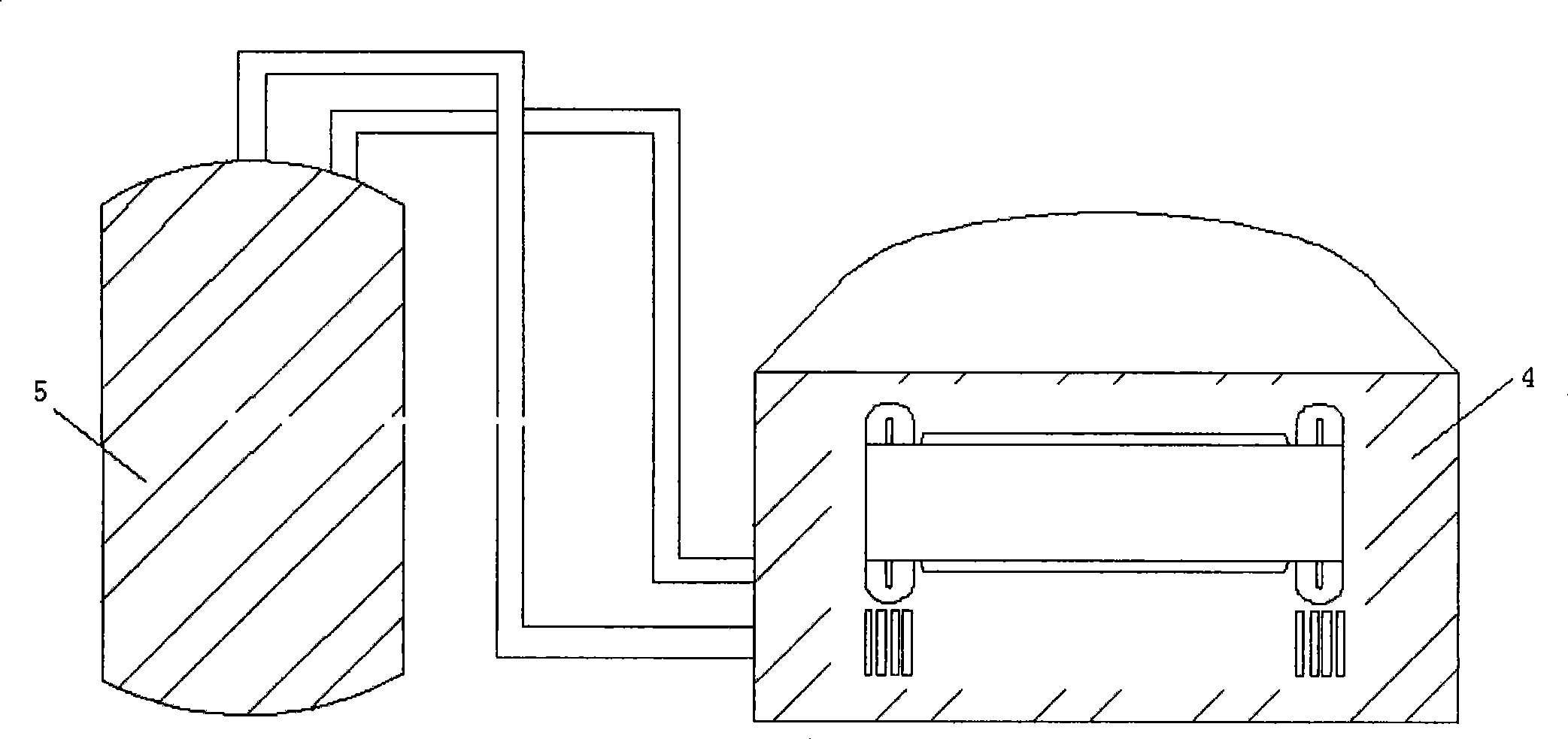

[0025] (3) Vacuuming: Cool the pre-baked motor stator to a specified temperature (such as 60-80°C), then hang it into the paint dipping tank 4, and evacuate it until the residual pressure is below 670Pa. The dipping paint in the paint storage tank 5 is slowly input into the dipping paint tank 4, and the liquid level of the paint is higher than the highest point of the motor stator to reach more than 40mm. During the impregnating paint input process, vacuumize the impregnating paint tank 4 continuously until the input paint liquid no longer bubbles, and then continue for 10 to 15 minutes before releasing the vacuum;

[0026] (4) Pressure impregnation: After the vacuum is released, pressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com