Reinforced concrete embedded type corrosion sensor

A corrosion sensor, reinforced concrete technology, applied in the field of sensors, to achieve the effects of convenient processing, simple and accurate testing methods, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

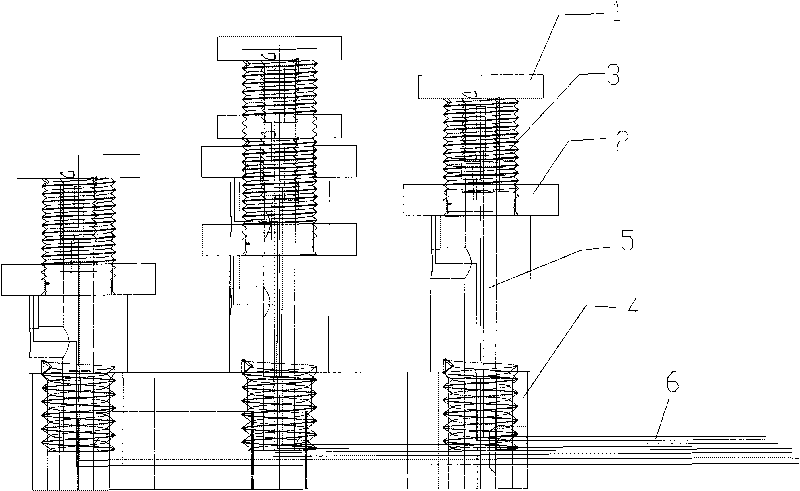

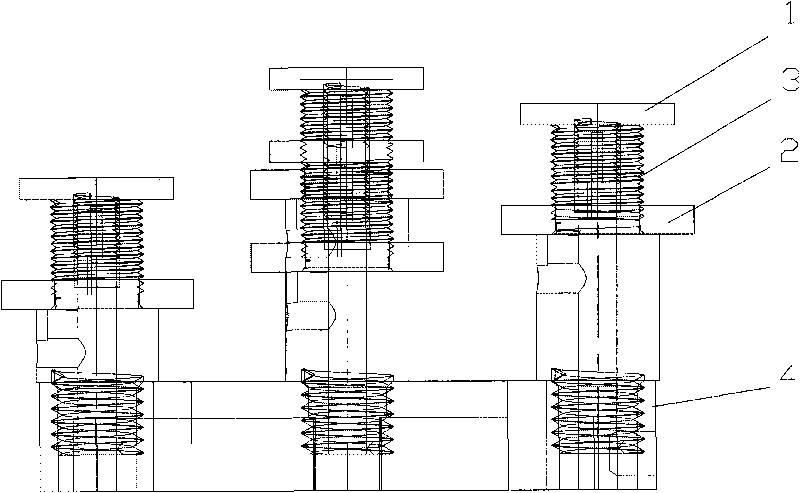

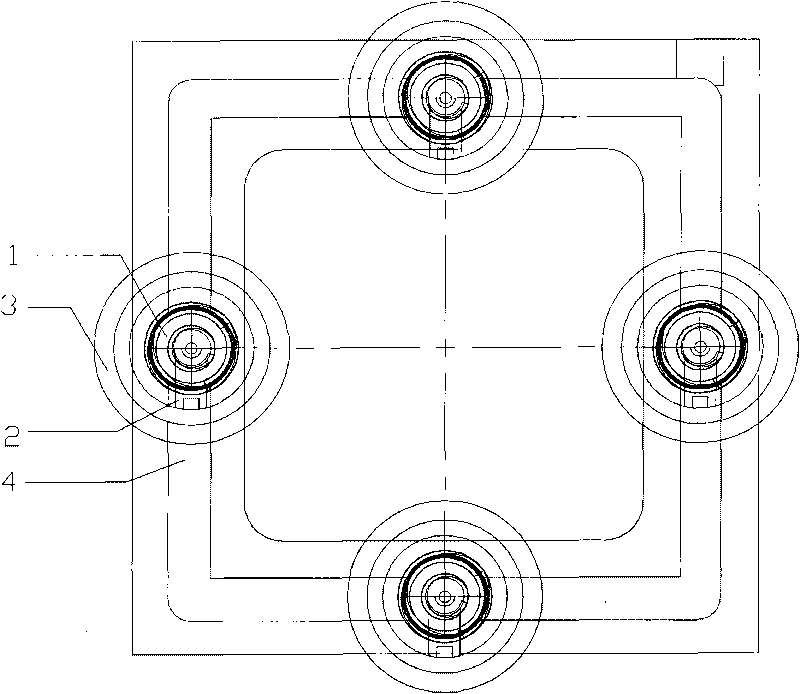

[0035] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0036] like Figure 1~3 As shown, the present invention is provided with 4 reinforced sheet anodes 1, 4 316L stainless steel sheet cathodes 2, 4 polyoxymethylene hollow rods 3, 1 polyoxymethylene base 5 and 1 eight-core wire 6. The steel sheet serves as the anode, and the 316L stainless steel sheet serves as the cathode, forming 4 pairs of galvanic couples with different heights. Each pair of galvanic couples is connected by a corresponding wire 6. The anode 1 of the steel sheet and the cathode 2 of the stainless steel sheet are kept parallel in the horizontal direction. In the vertical direction, the fixed difference is 12mm. The anodes 1 of the four reinforcement sheets are 5mm apart in the vertical direction. The connection of the whole sensor, such as steel sheet anode 1 and polyformaldehyde hollow rod 3, stainless steel sheet cathode 2 and poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com