Multi-dimensional transformation system of direct-shear test instrument of large-sized rock mass structure faces

A direct shear tester and conversion system technology, applied in the field of multi-scale conversion systems, can solve the problem of only measuring the shear strength of rock mass structural planes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

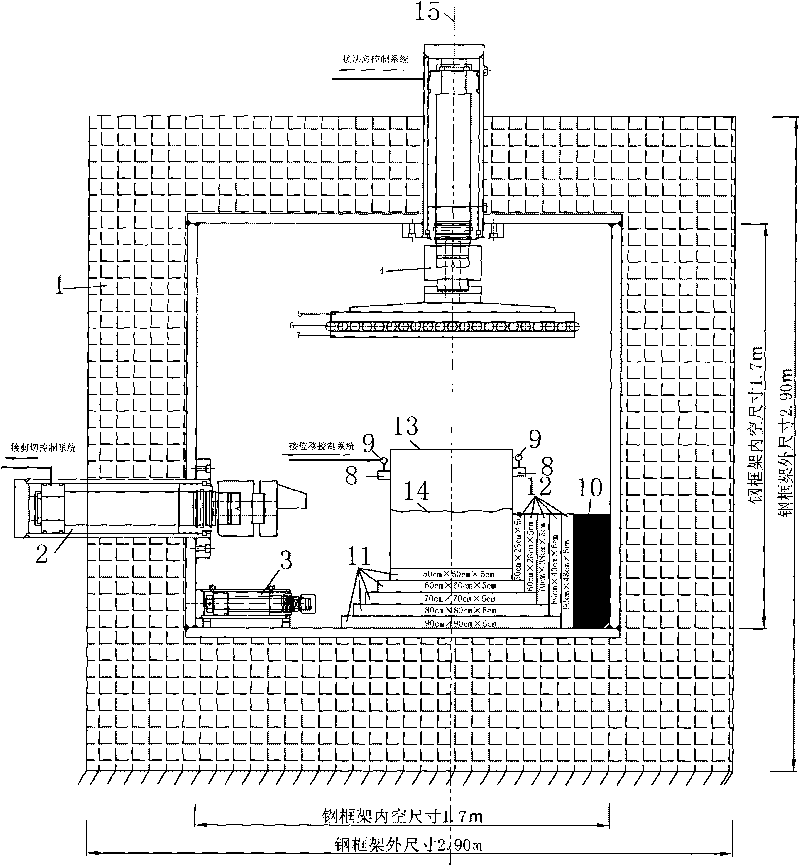

[0084] The present invention will be further described below in conjunction with the accompanying drawings.

[0085] refer to figure 1 and figure 2 , a multi-scale conversion system of a direct shear tester for a large-scale rock mass structural surface, the multi-scale conversion system includes n bottom backing plates 11 and n side backing plates 12, wherein n is a natural number, and 1≤n≤ 9. The n backing plates 11 are stacked sequentially from top to bottom according to the size of the area to form a bottom backing plate assembly. The area of the upper part of the bottom backing plate assembly is equal to the area of the bottom surface of the lower sample of the large-scale rock mass structural surface direct shear tester , the upper part of the backing plate assembly is in contact with the bottom surface of the lower sample under force, the lower part of the backing plate assembly is in force contact with the frame of the large-scale rock mass structural surface dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com