Fiber optic gyro coil wound by square section preformed fibers

A technology of fiber optic gyroscope and cross-section, which is applied in the direction of Sagnac effect gyroscope to achieve the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

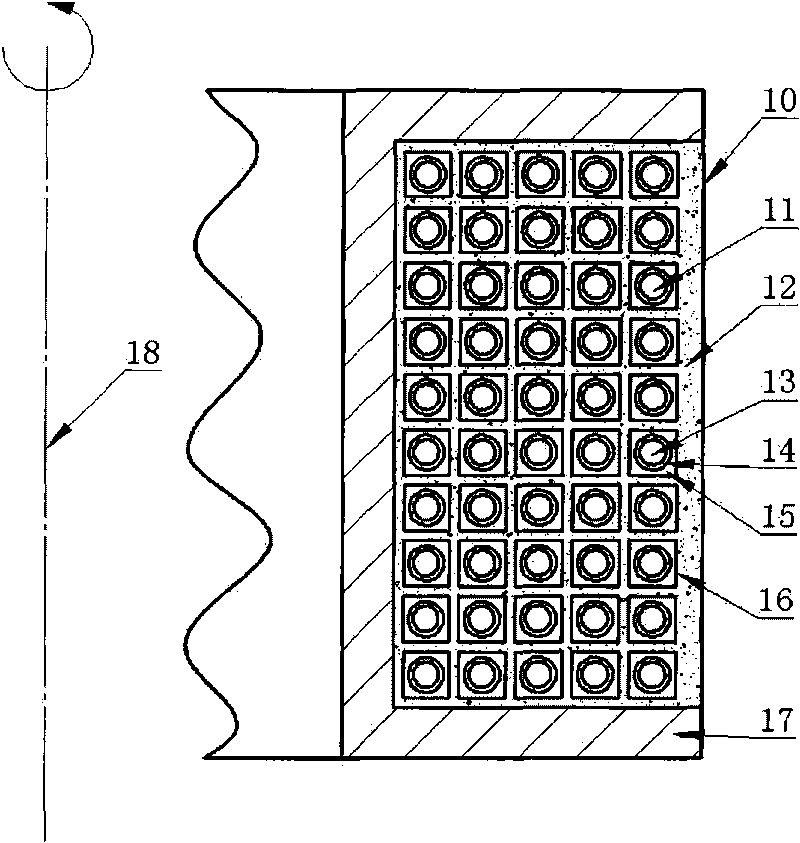

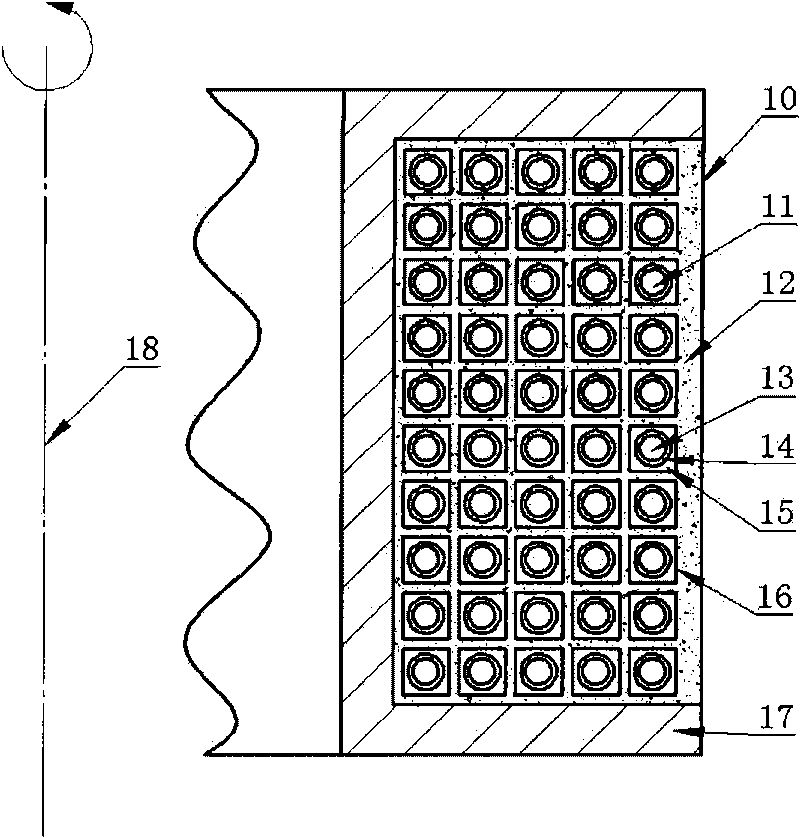

[0021] Such as figure 1 , figure 2 As shown, the fiber optic gyroscope coil 10 of the present invention is formed by winding a continuous prefabricated optical fiber 11 onto the skeleton 17 layer by layer using a quadrupole winding method or other symmetrical winding methods to enhance the reciprocity of the fiber optic gyroscope. The outer surface 16 of the optical fiber is always parallel to the coil axis 18 , and the gap between the optical fibers can be filled with an appropriate packaging material 12 .

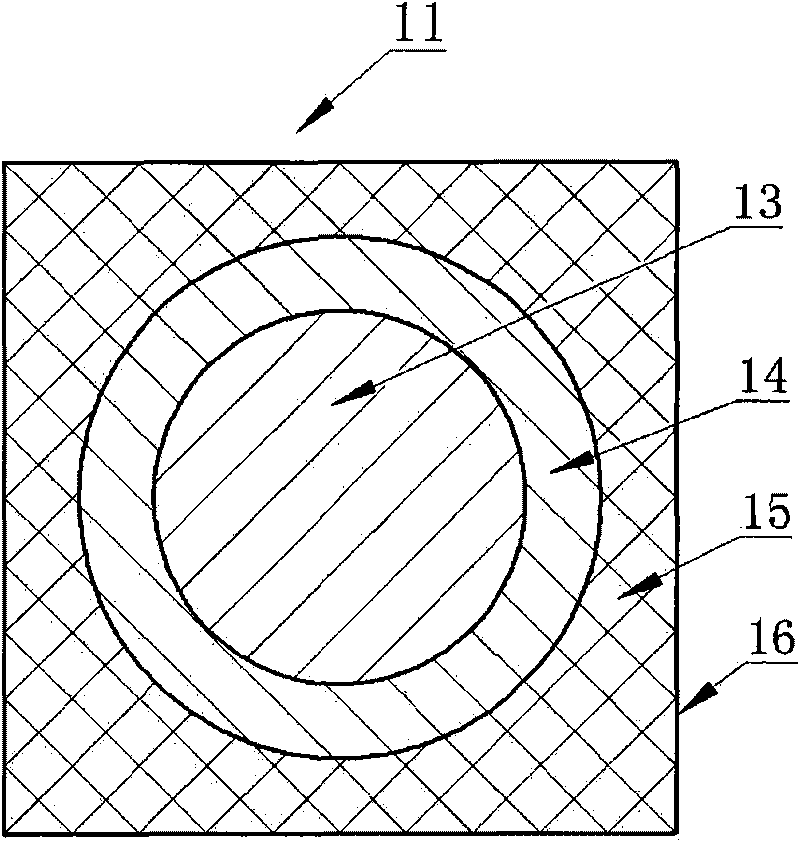

[0022] Such as figure 2 As shown, the prefabricated optical fiber 11 is formed by sequentially coating and curing the buffer layer 14 and the strengthening layer 15 outside the polarization maintaining or ordinary single-mode optical fiber 13; It is composed of a soft material with a very low thermal expansion coefficient and close to the polarization maintaining or ordinary single-mode optical fiber 13. An optional material is silicon rubber; It is composed of a har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com