Self-operated three-way reversing valve

A three-way reversing valve, self-operated technology, used in fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve the problems of unsatisfactory reliability, consumption of materials, and high production costs, and achieve high reliability, The effect of high sealing performance and improved cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

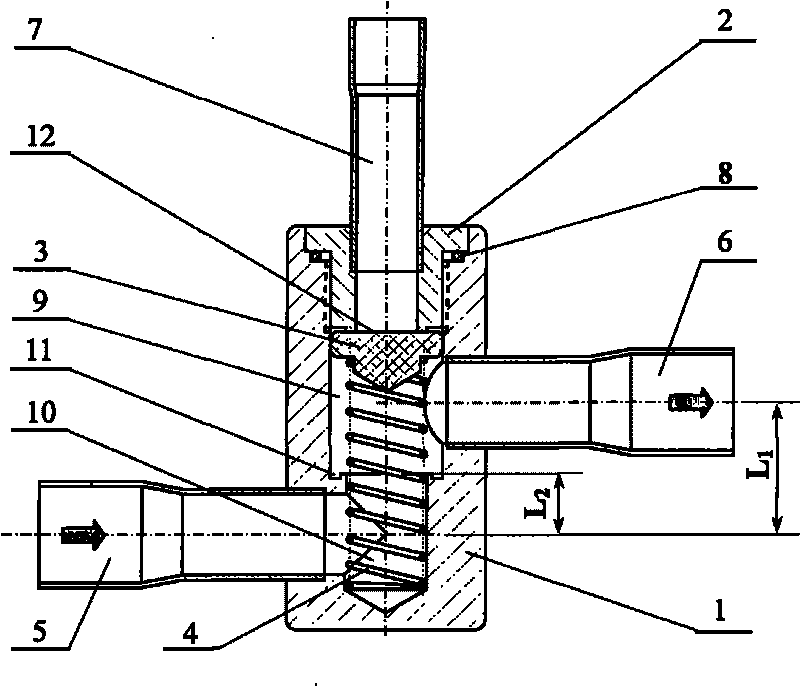

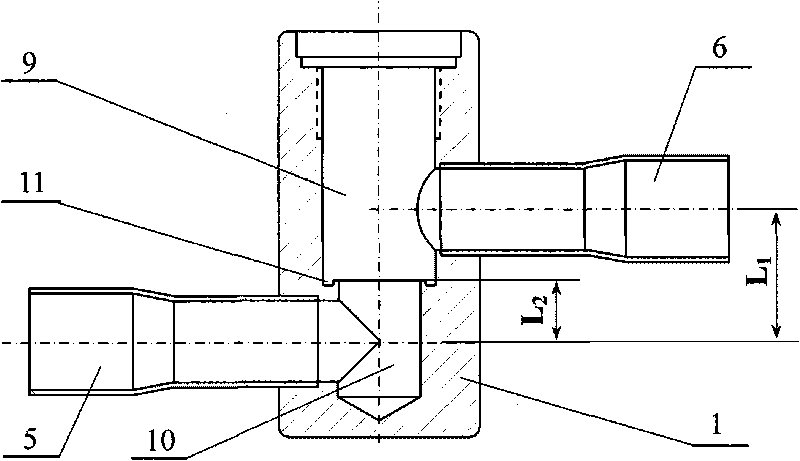

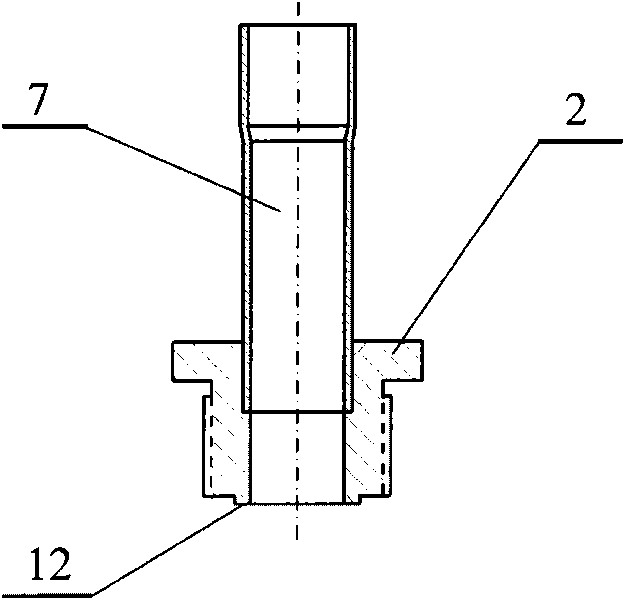

[0019] see figure 1 , 2 , 3 and Figure 4 The self-operated three-way reversing valve proposed by the present invention includes a valve body 1, a valve cover 2, a valve core 3, a spring 4, an evaporator connecting pipe 5, a condenser connecting pipe 6, a compressor exhaust connecting pipe 7, and a sealing ring 8; On the valve body 1, the evaporator connecting pipe 5 and the condenser connecting pipe 6 perpendicular to the axis of the valve body are arranged in dislocation, and the distance L between the axis line of the evaporator connecting pipe and the axis line of the condenser taking over 1 It should be greater than the sum of the inner radius of the evaporator connecting pipe 5 and the inner radius of the condenser connecting pipe 6; the compressor exhaust connecting pipe 7 is arranged on the valve cover 2, and a stepped hole with a large upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com