Hydraulic control one-way valve

A technology of hydraulically controlled one-way valves and pilot valves, which is applied in the direction of control valves, valve details, valve devices, etc., which can solve the problems of high hydraulic pressure, large impact force of subsequent components, and unstable startup of subsequent components, so as to reduce the impact force , start and reset smoothly, and reduce the effect of hydraulic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

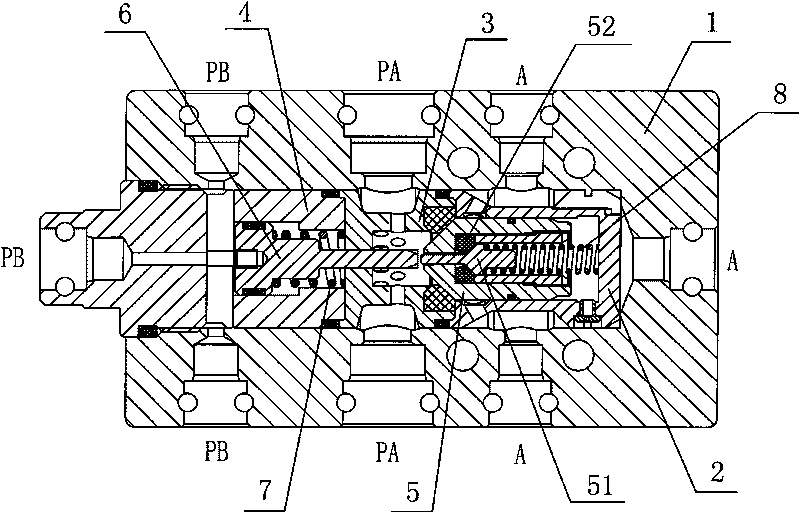

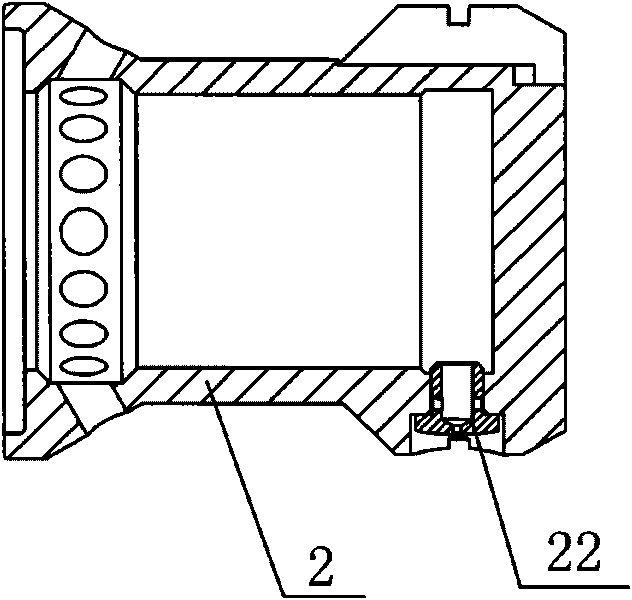

[0012] As shown in the figure, a hydraulically controlled one-way valve includes a valve body 1 and a pilot valve 2 sealed in the valve body 1, a valve seat 3 and a valve sleeve 4, and the valve seat 3 is arranged on the pilot valve 2 and the valve sleeve 4 Between, the pilot valve 2 is provided with a spool 5, the end of the spool 5 is connected to the valve seat 3, the spool 5 is provided with an auxiliary spool 51 and an auxiliary valve seat 52, and the front end of the auxiliary spool 51 extends Out of the front end of the spool 5, the distance between the front end surface of the auxiliary spool 51 and the front end surface of the spool 5 is 1mm, and a second spring 8 is connected between the rear end of the auxiliary spool 51 and the inner end surface of the pilot valve 2, The valve sleeve 4 is sealed with a piston 6. The end of the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com