Low-stress nickel plating technology

A technology of nickel plating and process, which is applied in the field of protective treatment of low-alloy high-strength steel parts, can solve problems such as fracture, and achieve the effects of simple process operation, uniform appearance, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

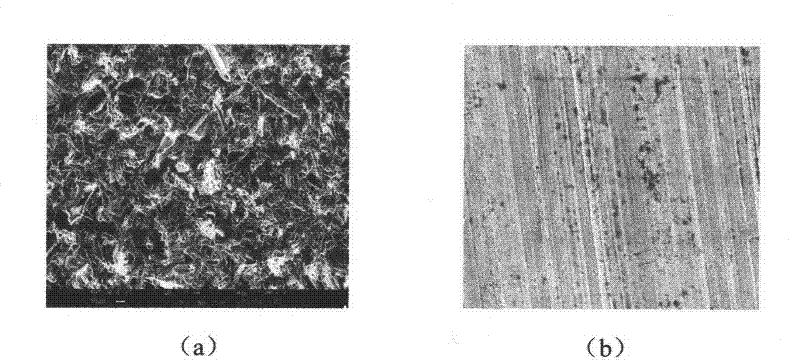

Image

Examples

Embodiment 1

[0045] Use a ¢0.8 steel wire to fold into a ¢75 circle, and dip it in the plating solution to check that the transparent film 30S of the bath is not broken. Put the CF6-80E engine front fan coupling nut at 246°C for 190 minutes to remove stress.

[0046] Anodic degreasing is performed on the stress-relieved parts in the degreasing tank, and the current density is 3.5A / dm 2 , electrolysis time 2min, temperature 60°C, check the water film on the surface of the plated parts for 20S continuous. Afterwards, put the degreased parts in a corrosion solution of 160ml / l hydrochloric acid and 1.5g / l rhodin for 0.6min.

[0047] The pre-treated parts are pre-plated with nickel in a pre-nickel bath, and the parts are placed in NiCl at 24°C (room temperature) 2 .6H 2 O 246.3g / l, HCl 190.7g / l pre-plating nickel solution for 3 minutes, then electroplating for 4 minutes, the current density is 6.5A / dm 2 , the part area (including fixture area) is 5dm 2 .

[0048] The pre-plated parts are ...

Embodiment 2

[0051] Use a ¢0.8 steel wire to fold into a ¢75 circle, and dip it in the plating solution to check that the transparent film 20S of the bath solution is not broken. Put the CF6-80E engine front fan coupling nut at 246°C for 180min to remove the stress.

[0052] Anodic degreasing of stress-relieved parts in the degreasing tank with a current density of 4A / dm 2 , electrolysis time 2min, temperature 60°C, check the water film on the surface of the plated material for 20S continuous. Afterwards, put the degreased parts in a corrosion solution of 190ml / l hydrochloric acid and 1.0g / l rhodin for 0.8min.

[0053] Use a pre-nickel-plating tank to pre-nickel the pre-treated parts, and place the parts in NiCl at 24°C (room temperature) 2 .6H 2 O 242.9g / l, HCl 190.1g / l pre-plating nickel solution for 3.5min, then electroplating for 4.5min, the current density is 6A / dm 2 , the part area (including fixture area) is 5dm 2 .

[0054] The pre-plated parts are nickel-plated in the nickel...

Embodiment 3

[0057] Use a ¢0.8 steel wire to fold into a ¢75 circle, and dip it in the plating solution to check that the transparent film 20S of the bath solution is not broken. Put the CF6-80E engine front fan coupling nut at 246°C for 180min to remove the stress.

[0058] Anodic degreasing of stress-relieved parts in the degreasing tank with a current density of 4A / dm 2 , electrolysis time 2min, temperature 60°C, check the water film on the surface of the plated material for 20S continuous. Afterwards, put the degreased parts in a corrosion solution of 160ml / l hydrochloric acid and 1.8g / l rhodin for 0.6min.

[0059] Use a pre-nickel-plating tank to pre-nickel the pre-treated parts, and place the parts in NiCl at 24°C (room temperature) 2 .6H 2 In the pre-plating nickel solution of O 242.3g / l and HCl 194.9g / l for 3 minutes, then electroplating for 4 minutes, the current density is 6.5A / dm 2 , the part area (including fixture area) is 5dm 2 .

[0060] The pre-plated parts are nickel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com