Automatic cutter relieving mechanism

A driving mechanism and automatic technology, applied in sawing machines, metal sawing equipment, metal processing equipment, etc., can solve the problems of reducing the service life of the saw blade, scratching the cutting section, affecting the cutting quality, etc., to improve the surface accuracy, machining High precision, saving the effect of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

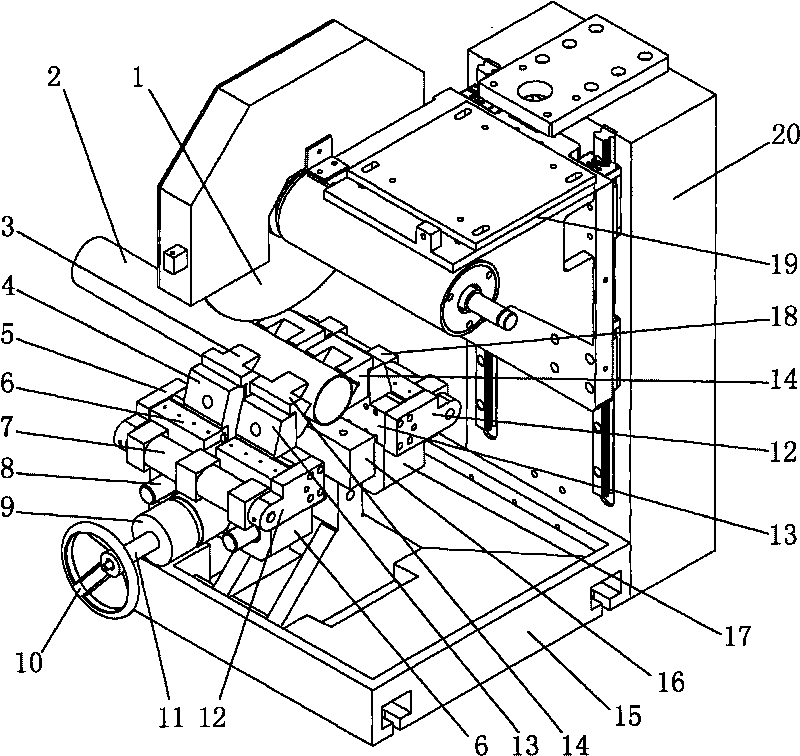

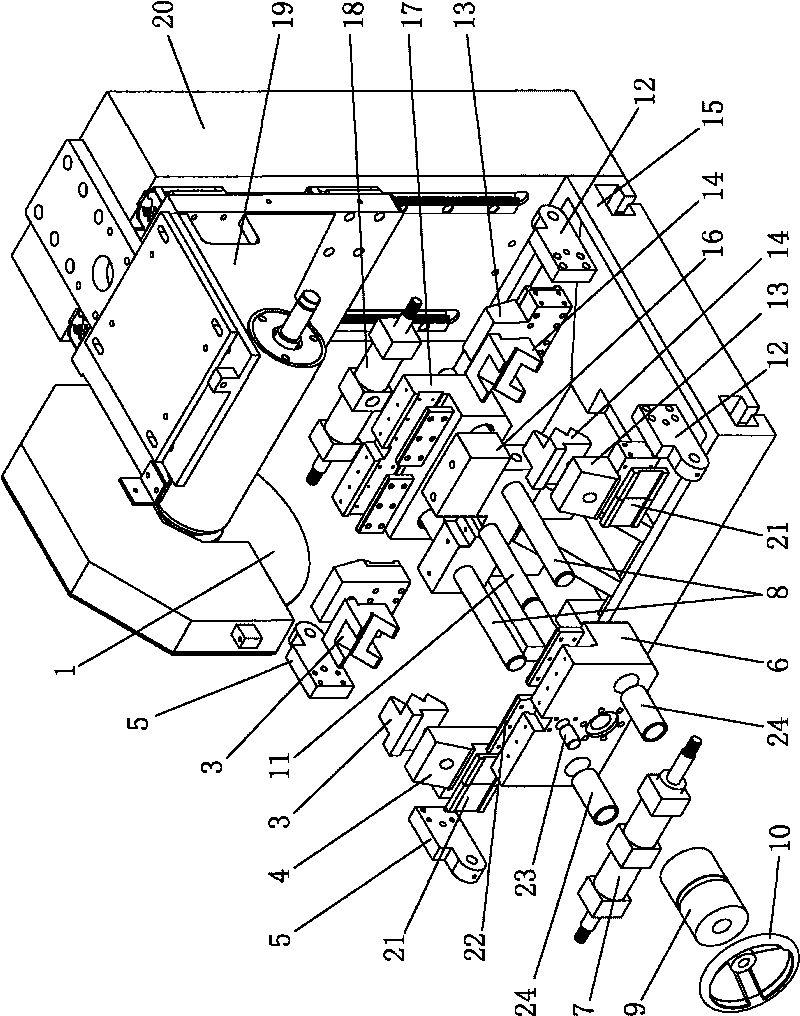

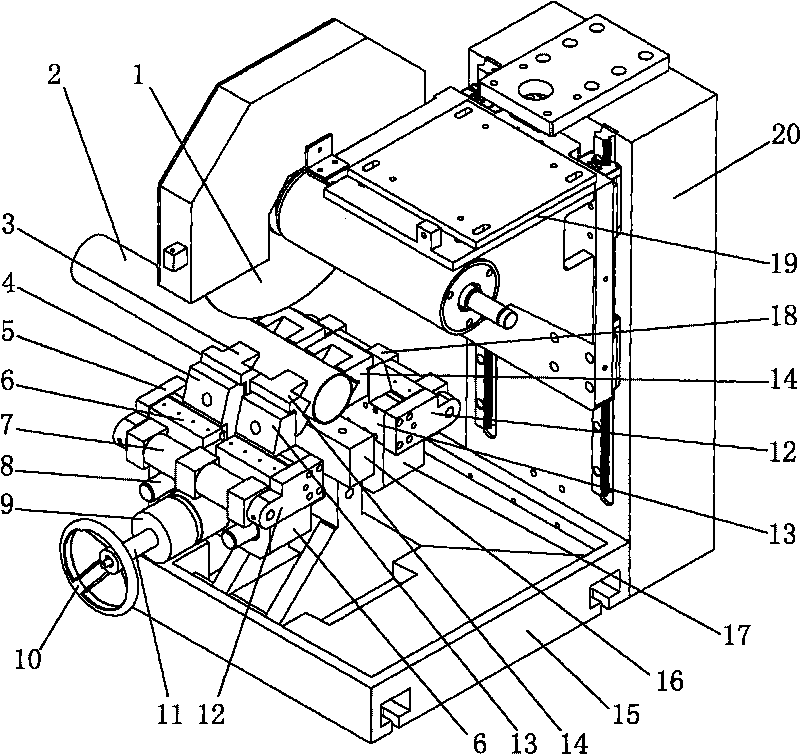

[0016] Such as figure 1 , figure 2 A kind of automatic tool letting mechanism shown, comprises the support 16 that is arranged on the base 15, and a main clamping screw 11 is erected on the support 16, and the axis of the main clamping screw 11 is parallel to the plane of the saw blade 1, and the main clamping screw 11 can rotate but cannot Move along its axial direction; the front main clamp body 6 and the rear main clamp body 17 are sleeved on the main clamp screw rod 11 respectively, the front main clamp body 6 and the main clamp screw rod 11 are empty, and the rear main clamp body 17 and the main clamp screw rod 11 Threaded connection, the front main clip body 6 and the rear main clip body 17 are respectively slidably connected with two main clip optical axes 8 erected on the bracket 16 in parallel with the main clip screw rod 11 through the guide sleeve 24, thus, the front main clip body 6 and the rear main clip body Rear main clip body 17 all can move relative to main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com