Construction method of constructional column prefabricated dent joint concrete module

A construction method and concrete technology, applied in the direction of building structure, formwork/formwork/working frame, and preparation of building components on site, to achieve the effects of enhancing integrity, ensuring construction quality, and reducing secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Construction column prefabricated horse tooth cha concrete module construction method of the present invention, comprises the following steps:

[0032] a. Prefabricate several horse-toothed concrete modules.

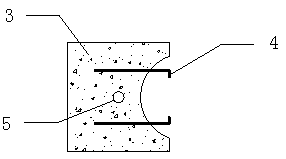

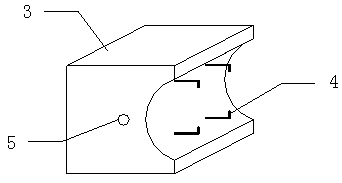

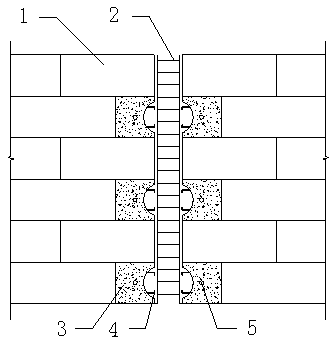

[0033] see now figure 1 , figure 1 is the front view of the lifting device of the embodiment of the present invention, figure 2 It is a side view of the lifting device of the embodiment of the present invention. As shown in the figure, several cube-shaped horse-toothed concrete modules 3 are prefabricated according to the size of the wall blocks. The width and height of the modules are the same as those of the wall blocks. There are 4 anchor bars arranged in correspondence with each other in the groove. One end of the anchor bar is left in the mosaic concrete module, and the other end is in the arc-shaped groove, which is even with the outer surface of the side module. A through hole parallel to the axis of the arc-shaped groove is provided at the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com