Purification system for inorganic coating spraying room

A technology of purification system and inorganic coating, which is applied in the direction of air conditioning system, ventilation system, heating and ventilation control system, etc. It can solve the problems affecting the quality of spraying, high manufacturing cost, human injury, etc., and achieve indoor dust reduction and simple structure , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

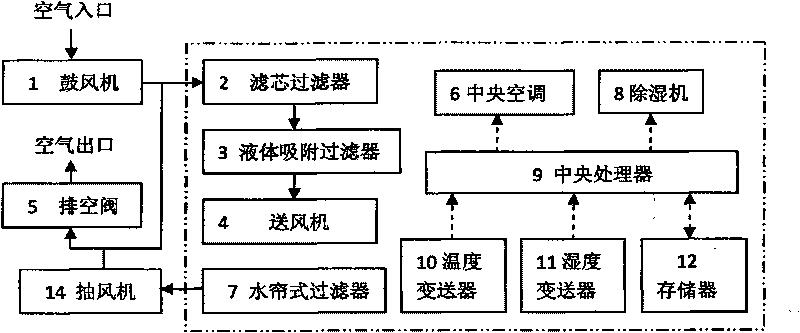

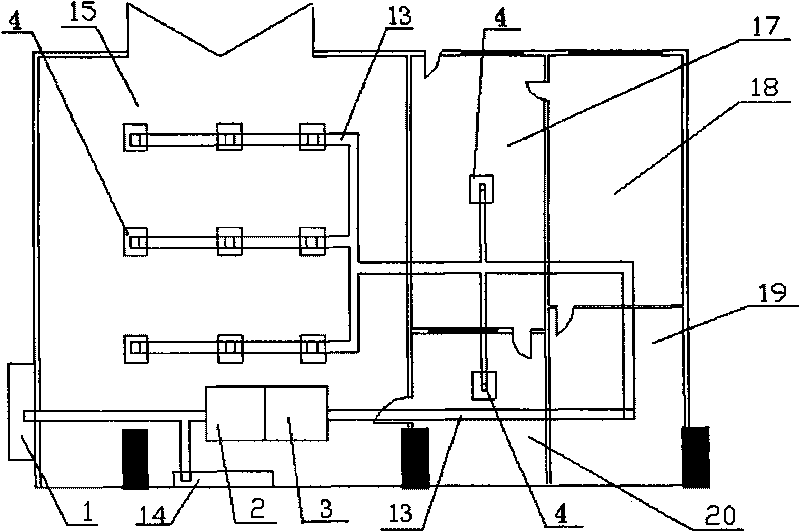

[0021] Such as figure 1 As shown, the present invention is a purification system for an inorganic coating spray booth, including an air purification system and a temperature and humidity control system.

[0022] The air purification system includes a blast subsystem and an exhaust subsystem.

[0023] The blower subsystem is a blower and filtration system, including a blower 1, a filter element filter 2, a liquid adsorption filter 3, and a blower 4 connected in sequence through a pipeline 13. The air inlet of the blower 1 is directly connected to the atmosphere. The filter element filter 2 and The liquid adsorption filter 3 achieves the purpose of purifying the air, so that the cleanliness of the air entering the spraying room from the outside meets the process requirements. The filter element filter 2 has a multi-stage filter element, and the particle size of the dust allowed to pass through the final filter element is smaller than 0.5μm. The efficiency of the liquid adsorpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com